A kind of transparent polylactic acid film and its preparation method and application

A polylactic acid and transparent technology, applied in the field of transparent polylactic acid film and its preparation, can solve the problems of poor toughness of transparent polylactic acid film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

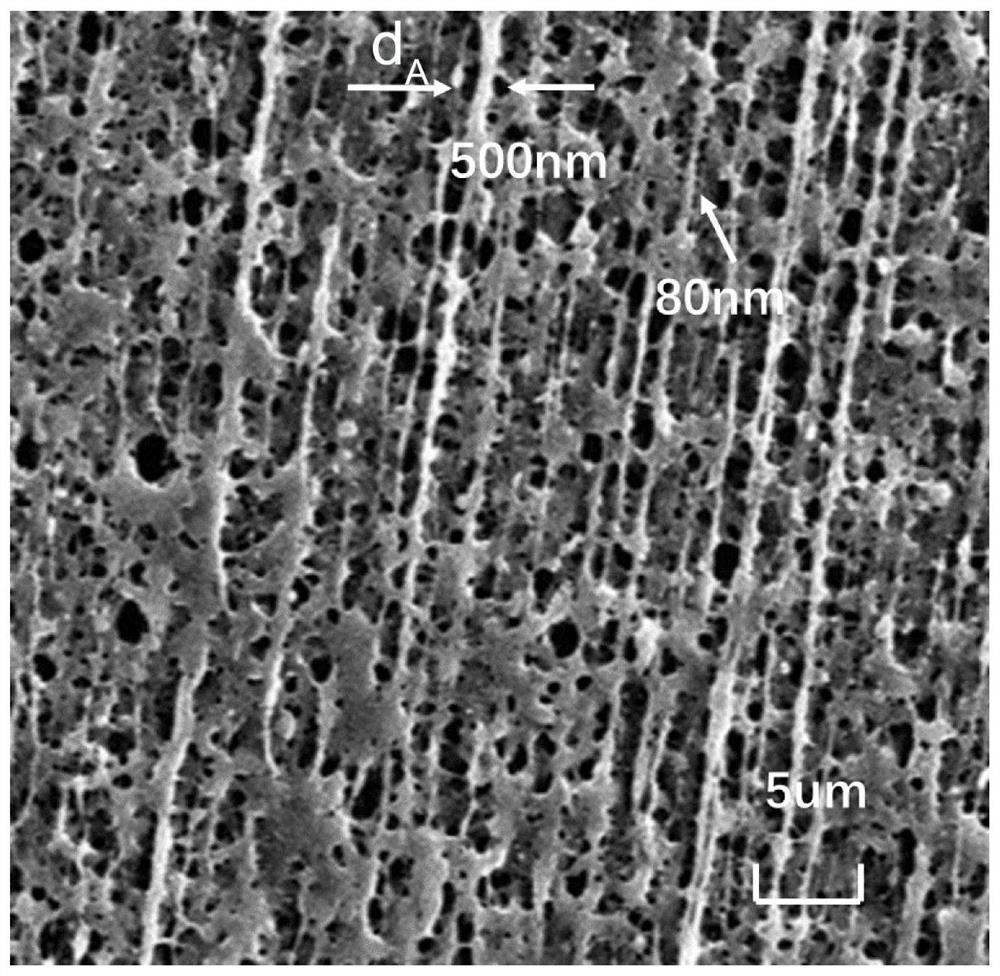

Image

Examples

Embodiment 1

[0051] In this embodiment, put the dried PLA-2003D polylactic acid with a melt index of 7.8g / 10min into the screw extruder when the temperature of the screw extruder reaches the preset temperature, wait for 3-5min, and start the device (air removal knife) ), PLA-2003D polylactic acid is melted, the melt is extruded by the screw extruder, and the air knife is turned on when the melt is stable Polylactic acid film; wherein, the temperature of the extruded film of the screw extruder is 190°C to 210°C, the ratio of the speed of the melt at the extruded film of the screw to the line speed of the casting roll is 1:40, and the air knife is set at the extruded film Between the casting roll and the direction of the tuyere of the air knife and the melt surface, the angle formed is 75°, the distance between the extrusion mouth film and the casting roll is 150mm, and the blowing volume of the air knife is 150m 3 / min, the blast temperature of the air knife is 10°C, and the roll temperatur...

Embodiment 2

[0054] In this embodiment, put the dried PLA-2003D polylactic acid with a melt index of 7.8g / 10min into the screw extruder when the temperature of the screw extruder reaches the preset temperature, wait for 3-5min, and start the device (air removal knife) ), PLA-2003D polylactic acid is melted, the melt is extruded by the screw extruder, and the air knife is turned on when the melt is stable Polylactic acid film; wherein, the temperature of the extruded film of the screw extruder is 190°C to 210°C, the ratio of the speed of the melt at the extruded film of the screw to the line speed of the casting roll is 1:120, and the air knife is set at the film extruded Between the casting roll and the direction of the tuyere of the air knife and the melt surface, the angle formed is 75°, the distance between the extrusion mouth film and the casting roll is 150mm, and the blowing volume of the air knife is 150m 3 / min, the blast temperature of the air knife is 10°C, and the roll temperatu...

Embodiment 3

[0057] In this embodiment, put the dried PLA-4043D polylactic acid with a melt index of 8g / 10min into the screw extruder when the temperature of the screw extruder reaches the preset temperature, wait for 3-5min, and start the device (air removal knife) , PLA-4043D polylactic acid is melted, the melt is extruded by the screw extruder and the air knife is turned on when it is stable, the melt is cooled by the air knife, then stretched by the casting roll, pulled by the traction roll, and the transparent poly Lactic acid film; wherein, the temperature of the extruded film of the screw extruder is 190 ℃ ~ 210 ℃, the ratio of the speed of the melt at the extruded film of the screw to the line speed of the casting roll is 1:40, and the air knife is set between the film at the extruded film and Between the casting rolls, the angle formed between the tuyere direction of the air knife and the surface of the melt is 75°, the distance between the extrusion film and the casting roll is 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com