Polylactic acid material with high stereocomplex crystal content and high molecular weight, and preparation method thereof

A polylactic acid material and a technology of stereocompositing, which is applied in the field of high molecular polymer materials, can solve the problems of poor stereo crystallization ability and weak crystal properties of left and right polylactic acid, and achieve the improvement of content and crystallization rate, low production cost, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

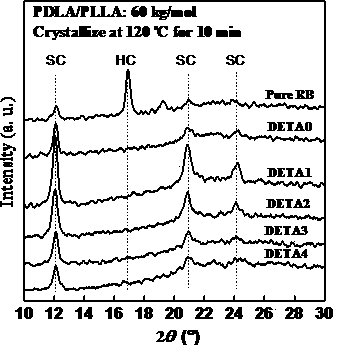

Image

Examples

preparation example Construction

[0022] The preparation method of the present invention comprises the following steps: Step 1, preparatory work: Weigh a certain amount of L-polylactic acid and D-polylactic acid and place them in a clean container, measure a certain amount of chloroform liquid, and divide it into three parts , weigh a certain amount of epoxy resin and amine curing agent and put them into clean containers respectively;

[0023] Step 2, preparation of the polylactic acid blend: dissolve the weighed L-polylactic acid and D-polylactic acid in one part of the chloroform liquid, stir with a magnetic stirrer for 5-8min, and the rotation speed is 200rpm;

[0024] Step 3, preparing epoxy resin solution: dissolving epoxy resin in the second part of chloroform liquid to prepare 1-3% epoxy resin solution;

[0025] Step 4, prepare the curing agent solution: configure the amine curing agent solution in another part of chloroform liquid to form a 0.05% to 0.6% curing agent solution;

[0026] Step 5, fully m...

Embodiment 1

[0028] The mass percentage of each component is: 5% of L-polylactic acid, 5% of D-polylactic acid, 2% of epoxy resin, 0.1% of diethylenetriamine, and 87.9% of chloroform.

Embodiment 2

[0030] The mass percentage of each component is: 5% of L-polylactic acid, 5% of D-polylactic acid, 2% of epoxy resin, 0.2% of diethylenetriamine, and 87.8% of chloroform.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com