Preparation method of composite reactive black dye

A technology of reactive black and dyes, which is applied in the field of preparation of composite reactive black dyes, can solve the problems of increasing the difficulty of color matching, low solid content of slurry, and high energy consumption, so as to save reaction time, dye shade and The effect of increasing yield and improving liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1: preparation of raw material sulfomethyl J acid

[0042] Add 23.93g of 100% J acid into a 500mL four-necked flask, add 140mL of water to disperse evenly, raise the temperature to 40°C, adjust the pH to 6.3-6.5 with 30wt% liquid caustic soda until dissolved, continue to add 16g of sodium hydroxymethanesulfonate solid, mix After homogeneity, use soda ash dry powder to maintain pH 6-6.5, keep warm at 40°C and react for 4-5 hours until the acid reaction is completed. The reaction solution was concentrated and crystallized under reduced pressure, and dried to obtain a solid of sulfomethyl J acid with a yield of over 95%.

Embodiment 2

[0043] Embodiment 2: preparation of composite reactive black

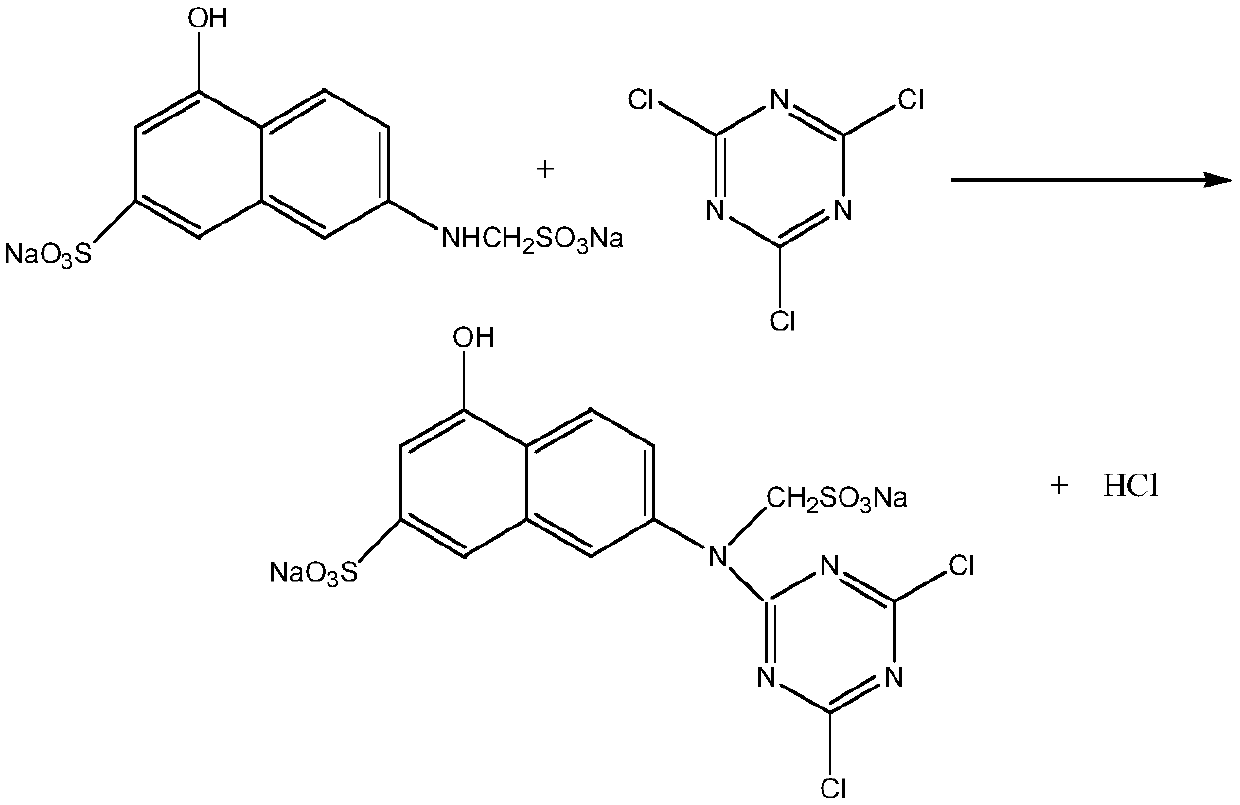

[0044] (1) One condensation

[0045] Weigh 3.73g of cyanuric chloride and place it in a 500mL beaker in an ice bath at 0-3°C for beating for 30min. After the beating is completed, add 7.39g of sulfomethyl J acid dry powder and continue beating for 1h. Use a mixed alkali solution of soda ash and baking soda (soda ash The mass ratio to baking soda is 2:3), adjust and maintain the pH at 3.5-4, control the temperature at 3-8°C, and react for 2-3 hours until the end point is reached.

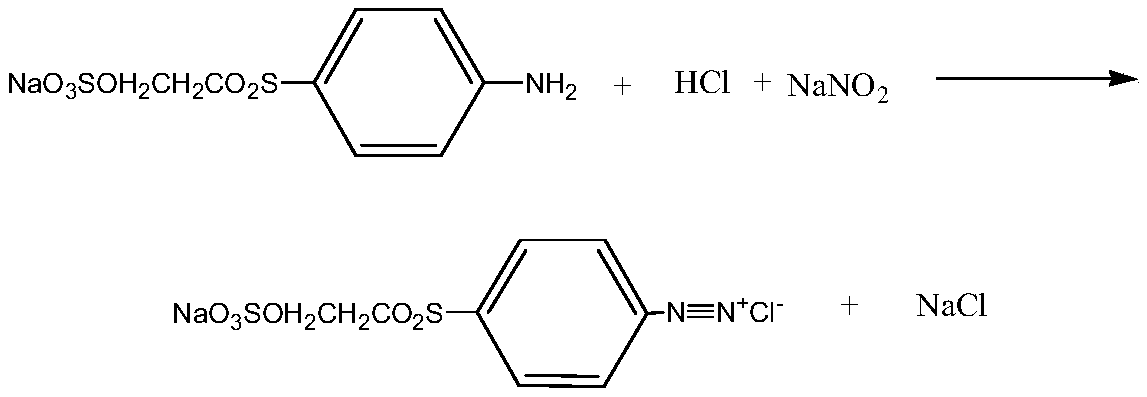

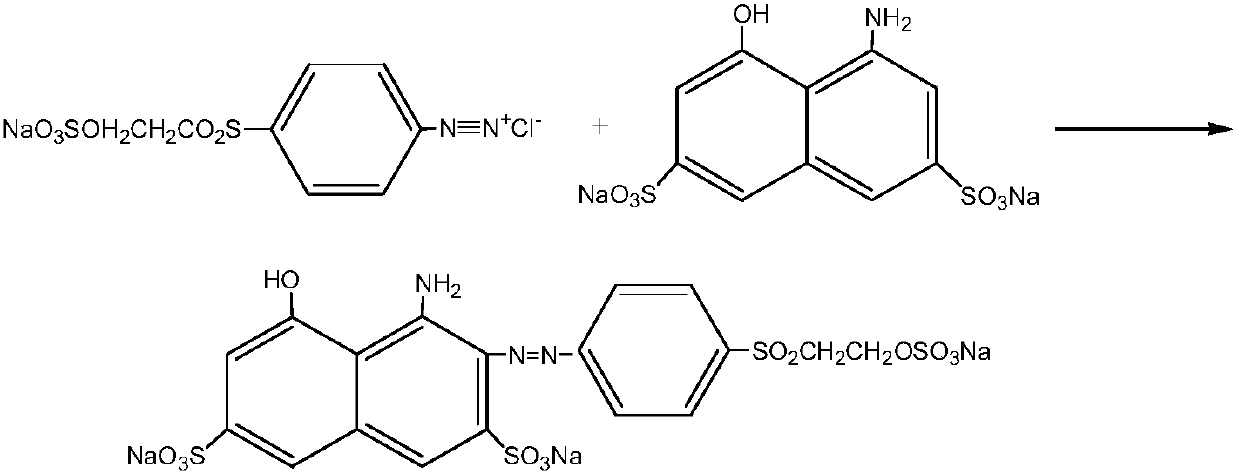

[0046] (2) para-ester diazo

[0047] Take by weighing 28.29g of para-ester percent (the mol ratio of para-ester and H acid is 1:0.385, and the mol ratio of para-ester and sulfomethyl J acid is 1:0.2) in a 1000mL beaker for beating in an ice bath, After beating, add technical amount of hydrochloric acid, stir for 5 minutes, continue to add technical amount of sodium nitrite, after 10-15 minutes, the pH is 1-1.3, keep warm at 2-5°C, and r...

Embodiment 3

[0052] Embodiment 3: preparation of composite reactive black

[0053] (1) One condensation

[0054] Weigh 2.8g of cyanuric chloride, place it in a 500mL beaker in an ice bath at 0-3°C for beating for 30min, and after the beating is completed, add 5.54g of sulfomethyl J acid dry powder to continue beating for 1h, using a mixed alkali solution of soda ash and baking soda (soda ash The mass ratio to baking soda is 2:3), adjust and maintain the pH at 3.5-4, control the temperature at 3-8°C, and react for 2-3 hours until the end point is reached.

[0055] (2) para-ester diazo

[0056] Take by weighing 28.02g of the para-ester equivalent (the mol ratio of the para-ester to the H acid is 1:0.413, and the mol ratio of the para-ester to the sulfomethyl acid is 1:0.147) and make a slurry in an ice bath in a 1000mL beaker, After beating, add technical amount of hydrochloric acid, stir for 5 minutes, continue to add technical amount of sodium nitrite, after 10-15 minutes, the pH is 1-1.3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com