Factory prefabricated outdoor electrical equipment base, and manufacturing method and mounting method thereof

A technology of factory prefabrication and power equipment, applied in infrastructure engineering, manufacturing tools, ceramic molding machines, etc., can solve the problems of construction efficiency, difficult control of construction quality, low turnover rate and industrialization degree, and high construction complexity. The quality is easy to control, the turnover rate and the degree of industrialization are high, and the effect of reducing construction waste and dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

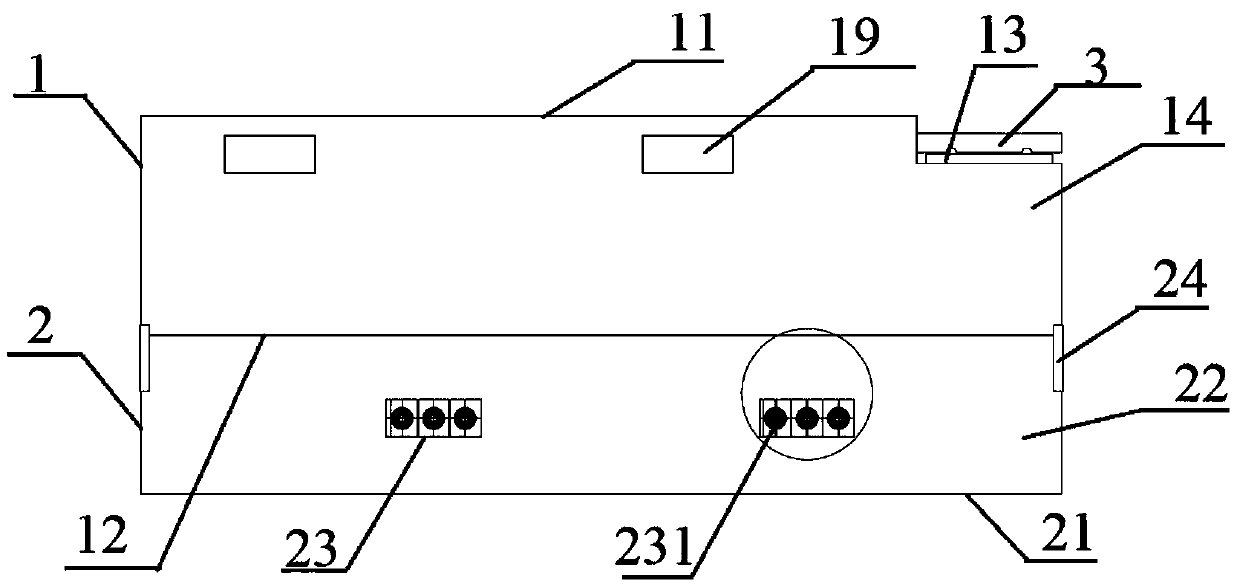

Embodiment 1

[0044] The factory prefabricated outdoor power equipment foundation described in this embodiment, see Figure 1-7 , including an upper foundation 1, a lower foundation 2 and a manhole cover 3, the lower foundation 2 is connected with the upper foundation 1, the upper foundation 1 is provided with a foundation upper opening 11, a foundation lower opening 12 and a lower wellhead 13, the lower foundation The wellhead 13 is provided with a well cover 3; the lower foundation 2 is an integrally formed rectangular box structure composed of a lower bottom plate 21 and a lower foundation side plate 22; Formed rectangular frame construction. The side wall of the lower foundation 2 is provided with several cable holes 23; the cable hole 23 is provided with a cable sealing device 231, see Figure 8 And Fig. 9; the upper part of the side wall of the upper foundation 1 is provided with several ventilation openings 19, and the ventilation openings 19 are provided with mesh covers. The uppe...

Embodiment 2

[0046] The manufacturing method of the factory prefabricated outdoor power equipment foundation described in Embodiment 1 includes the following steps:

[0047] (1) Design the reinforcement drawings of the upper foundation 1, the lower foundation 2 and the manhole cover 3 according to the outline and structural dimensions of the drawings of the factory prefabricated outdoor power equipment foundation;

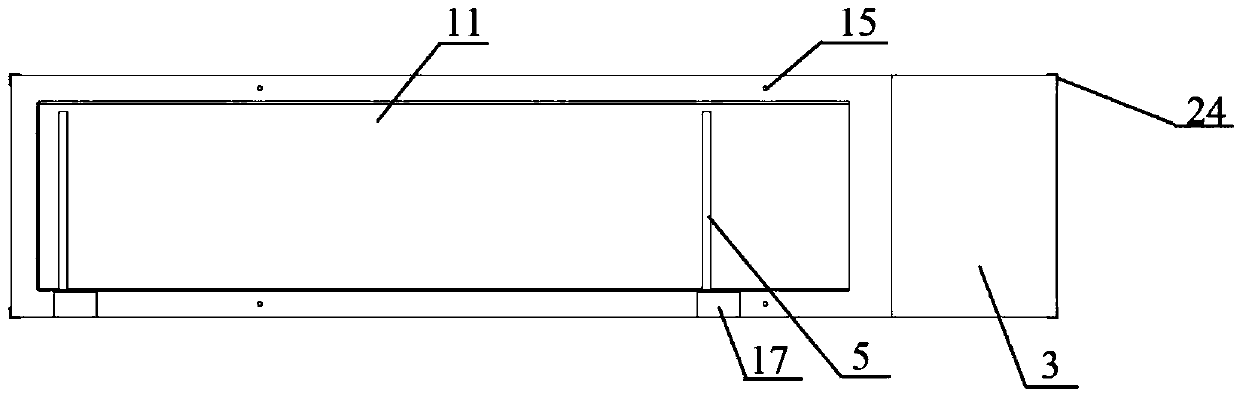

[0048] (2) According to the reinforcement diagram of upper foundation 1, lower foundation 2 and manhole cover 3 described in step (1), bend and bind the reinforcement skeleton, at the position required by the drawing in step (1), place the reinforcement on upper foundation 1 and lower foundation 2 Fix the hoisting embedded part 15, install the embedded part 16, the first metal conductor 17, the second metal conductor 18, and the guide part 24 in the skeleton, connect the first metal conductor 17 and the steel bar inside the upper foundation 1 by welding, and connect all the The...

Embodiment 3

[0055] The installation method of the factory prefabricated outdoor power equipment foundation described in Embodiment 1 includes the following steps:

[0056] (1) The lower foundation 2 is fully buried underground, pouring mortar on the upper surface of the lower foundation 2, and then the upper foundation 1 is installed on the upper surface of the lower foundation 2 through the guide 24 on the lower foundation 2;

[0057] (2) The air vent 19 on the upper part of the side wall of the upper foundation 1 is exposed to the ground, and the wellhead 13 of the lowering is higher than the ground, and the cable support 4 is fixed by screwing on the inner surface of the upper foundation side plate 14 by installing the embedded part 16 Connecting, connecting the ground bus bar 5 to the first metal conductor 17, the second metal conductor 18, and the cable support 4, and the lower end of the ground bus bar 5 extends to the lower base plate 21 of the lower foundation 2;

[0058] (3) A ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com