Circular-hole-installed honeycombed beam reinforced by using carbon fiber reinforced composite material

A technology of reinforcing composite materials and circular holes, which is used in building maintenance, construction, building construction, etc., can solve the problem of easy local instability of the edge of the hole of the honeycomb beam, and achieves clear and definite force, small volume, and construction period. short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

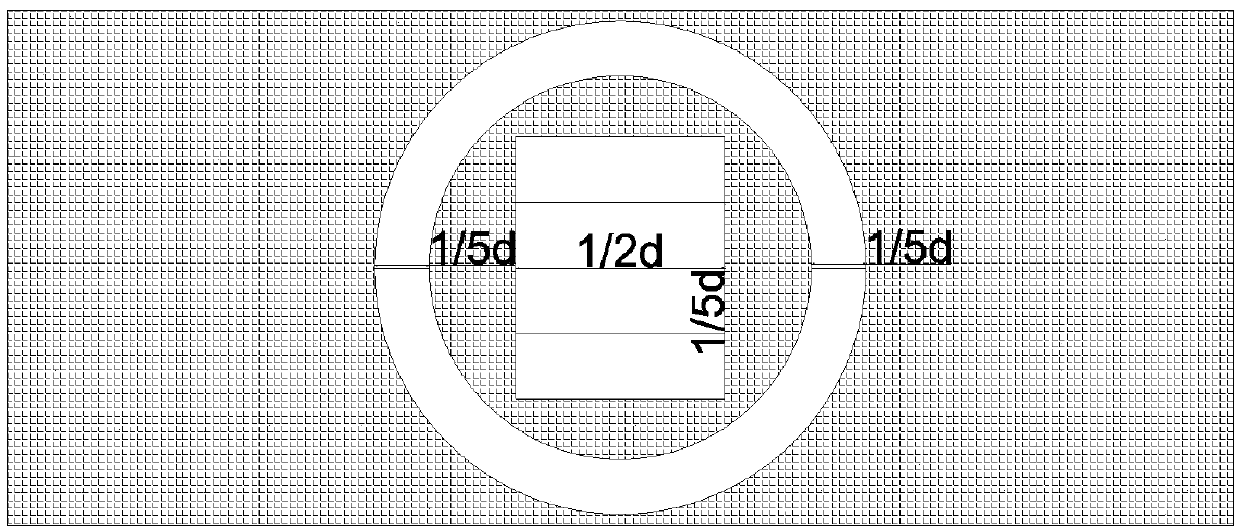

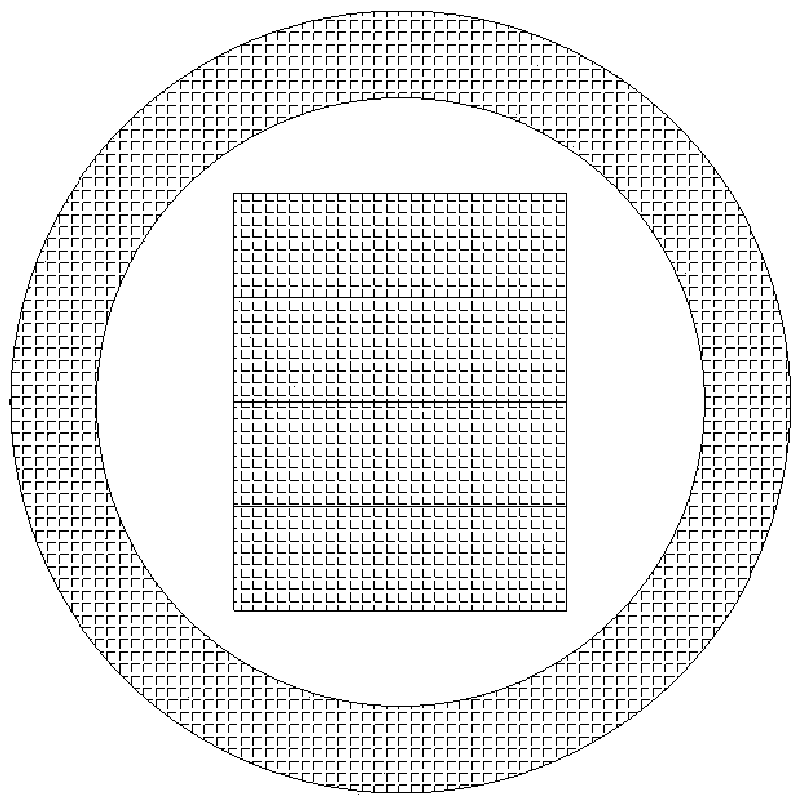

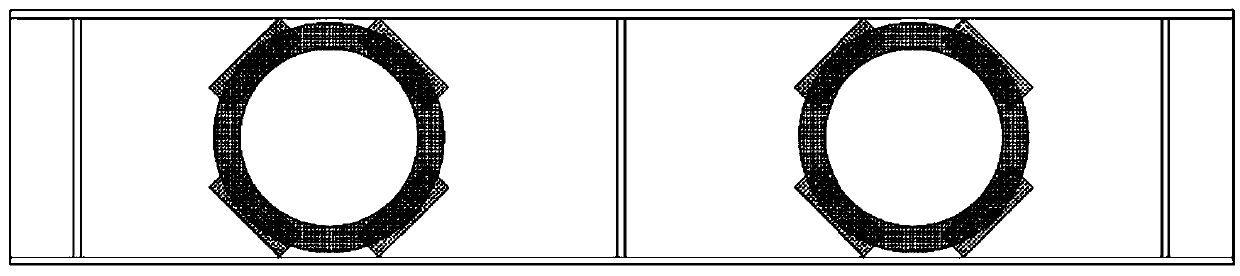

[0020] The carbon fiber cloth shown in Figure 1 should first be made according to the required size. The honeycomb steel beam strengthened by the carbon fiber composite material of the present invention comprises a honeycomb beam 1-1 with circular holes, a strip carbon fiber cloth 1-2 and an annular carbon fiber cloth 1-3.

[0021] The honeycomb beam with circular holes is an I-shaped steel beam, and a circular hole is opened between every two stiffeners. The two kinds of carbon fiber cloth should be cut out in the way shown in Figure 1 in a large carbon fiber cloth, which can save the carbon fiber cloth material. As shown in Figure 1, the diameter of the inner circle of the ring is the diameter of the circular opening, and the width of the ring is 1 / 5-1 / 3 of the diameter of the circular hole. Each strip of carbon fiber composite material i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com