Ninefold molten bamboo salt high-temperature melting furnace system and preparation method of ninefold molten bamboo salt

A melting furnace and sub-melting technology, applied in furnaces, crucible furnaces, furnace components, etc., can solve the problems that the quality of molten bamboo salt cannot be guaranteed, it is impossible to collect bamboo salt in a large area, and the bamboo salt that cannot be melted can be collected at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The objects and functions of the present invention and methods for achieving the objects and functions will be clarified by referring to the exemplary embodiments. However, the present invention is not limited to the exemplary embodiments disclosed below; it can be implemented in various forms. The essence of the description is only to help those skilled in the relevant art comprehensively understand the specific details of the present invention.

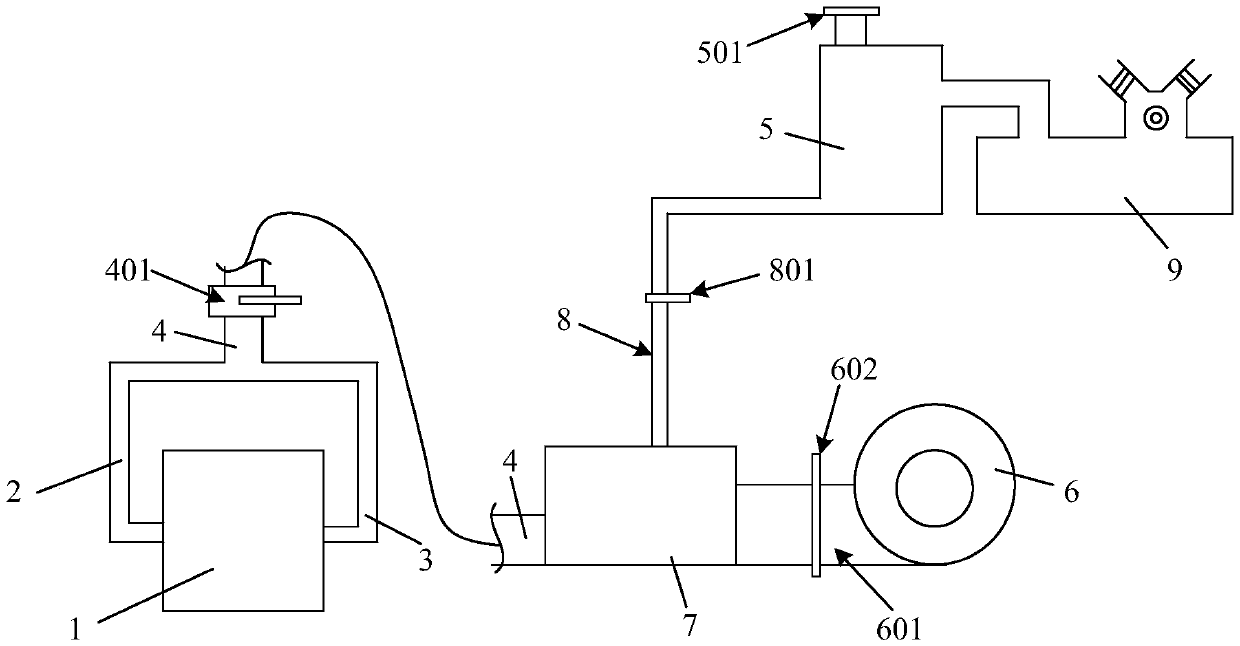

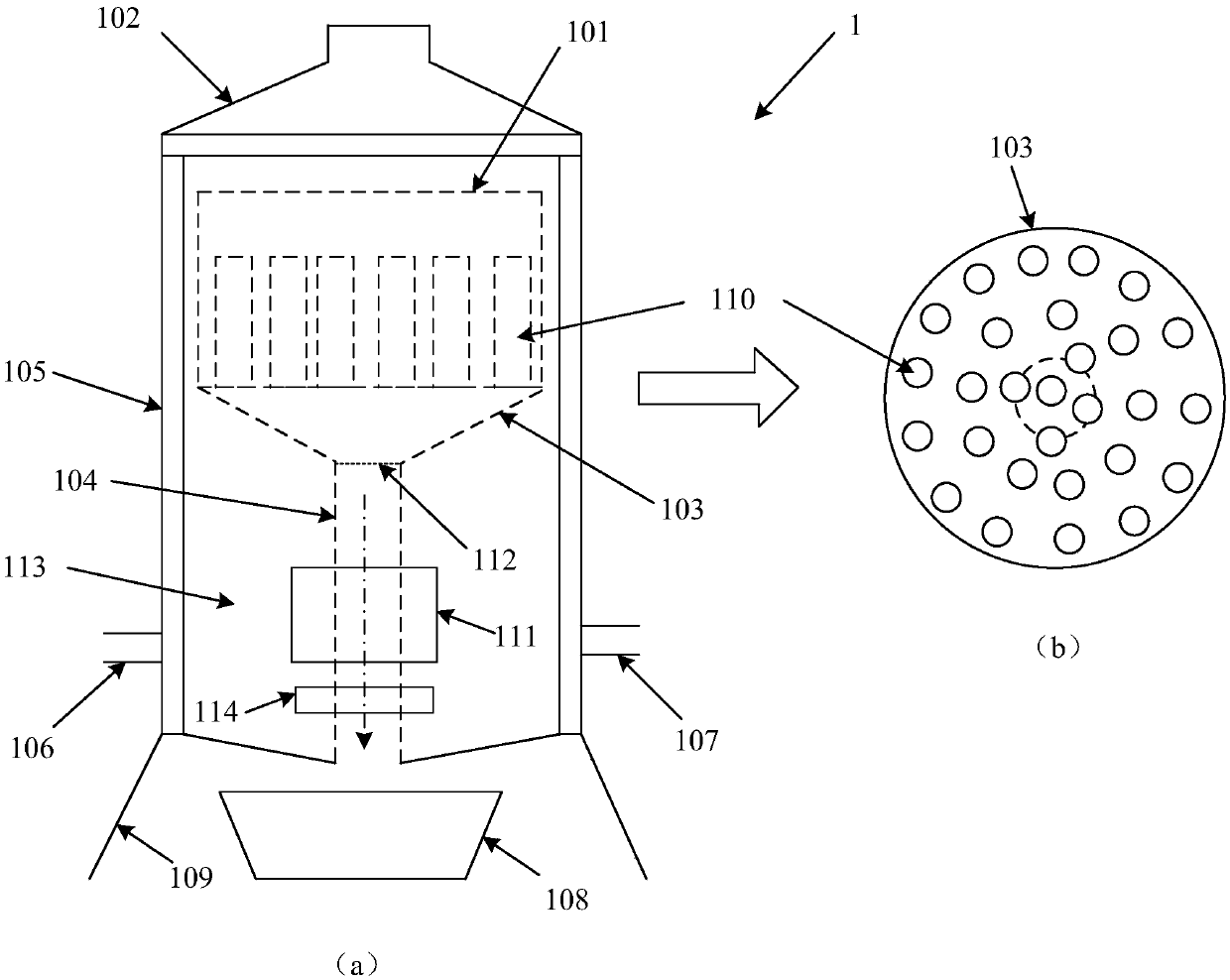

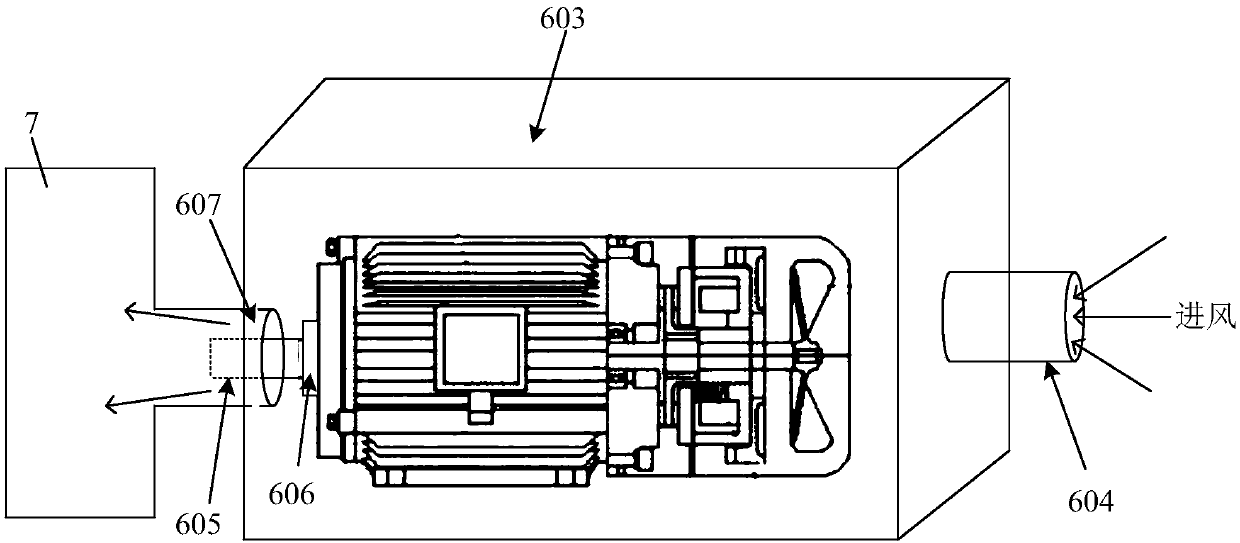

[0034] Hereinafter, embodiments of the present invention will be described with reference to the accompanying drawings, and related technical terms should be familiar to those skilled in the art. In the drawings, the same reference numerals represent the same or similar components, or the same or similar steps, unless otherwise specified. A kind of nine times of melting bamboo salt high temperature melting furnace system provided by the present invention and the preparation method of nine times of melting bamboo salt are des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com