A safety ignition device that can effectively prevent jamming

An ignition device and caliper technology, which is applied to offensive equipment, fuzes, weapon accessories, etc., can solve the problems of reducing the success rate of weapon system launch, threatening the survivability of weapons and equipment on the battlefield, and prone to caving, and achieve symmetrical force. The structure design is smooth, the launch reliability is improved, and the effect of preventing the jamming phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings.

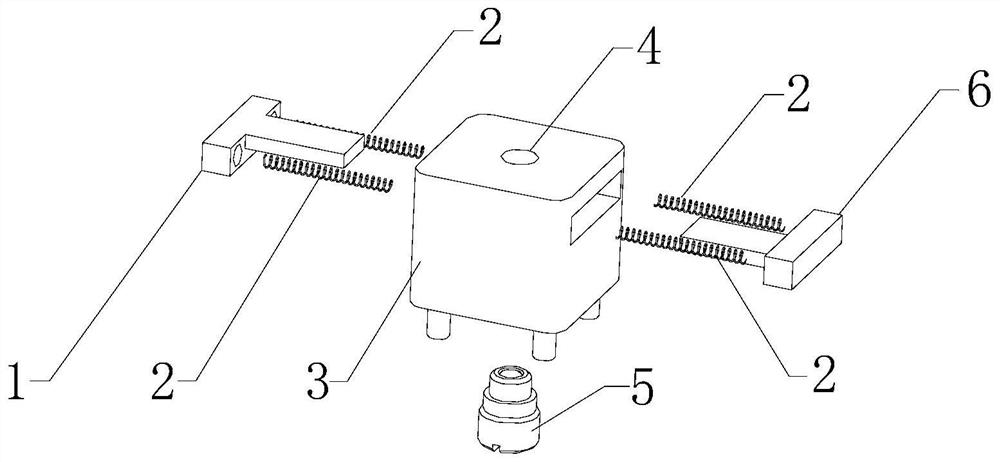

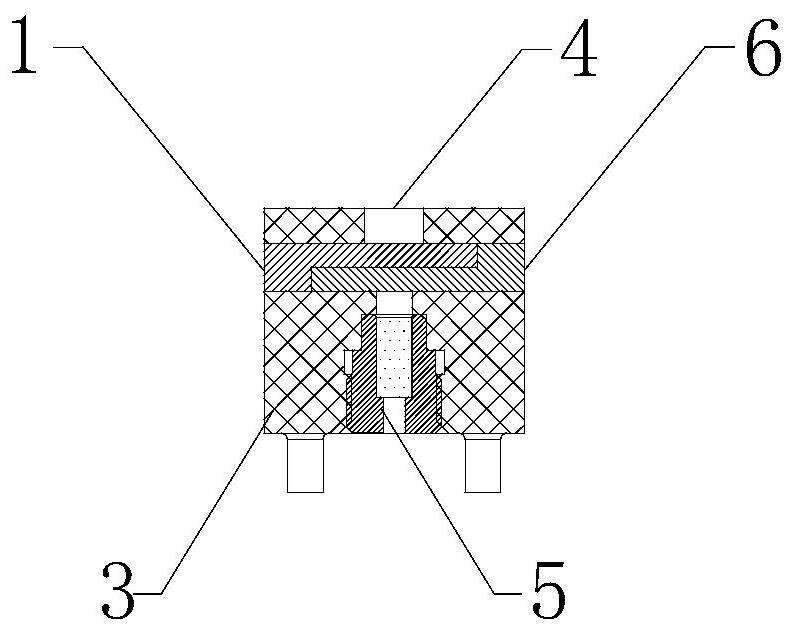

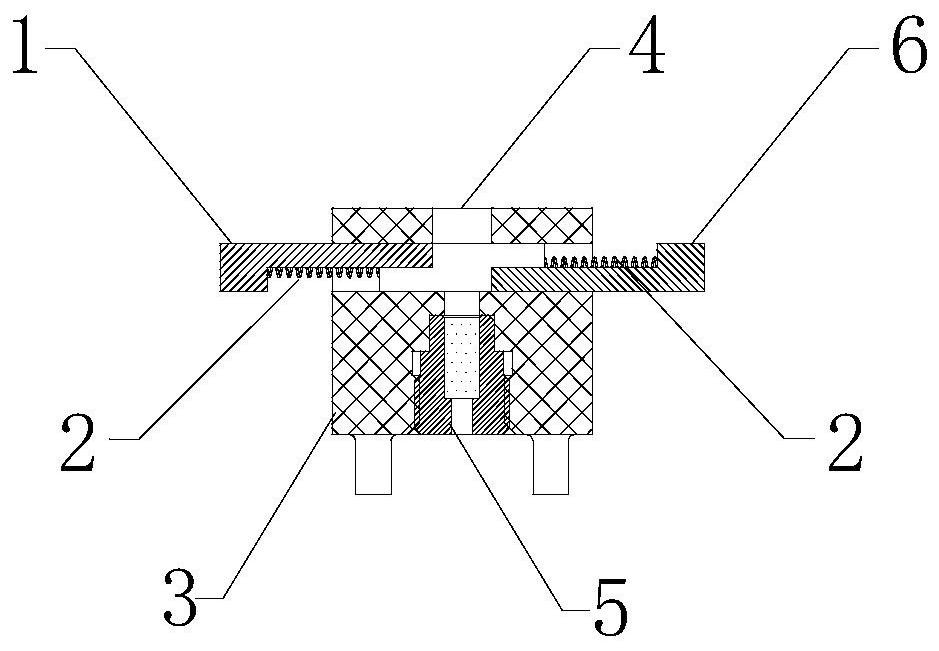

[0019] combine figure 1 , figure 2 , image 3 and Figure 8 , a safety ignition device that can effectively prevent jamming, including a first baffle plate 1, a second baffle plate 6, a piston body 3, a fire tube 5 and four springs 2, and the piston body 3 opens from the center of the top surface to the bottom surface There is a central through hole as the fire transmission channel 4, the fire transmission tube 5 is arranged in the fire transmission channel 4, and is located at the lower part of the fire transmission channel 4, and its bottom surface is flush with the bottom surface of the piston body 3, and the first baffle plate 1 is symmetrically arranged Two springs 2, two springs 2 are symmetrically arranged on the second baffle 6, baffle grooves are respectively symmetrically opened on the two axially symmetrical side walls of the piston body 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com