Research experiment device and method of tiny particle sample crushing process

A technology for sample crushing and tiny particles, which is used in measuring devices, using stable tension/pressure to test the strength of materials, instruments, etc. It can solve the problems of difficult real-time monitoring, short sample crushing process, and inaccurate results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

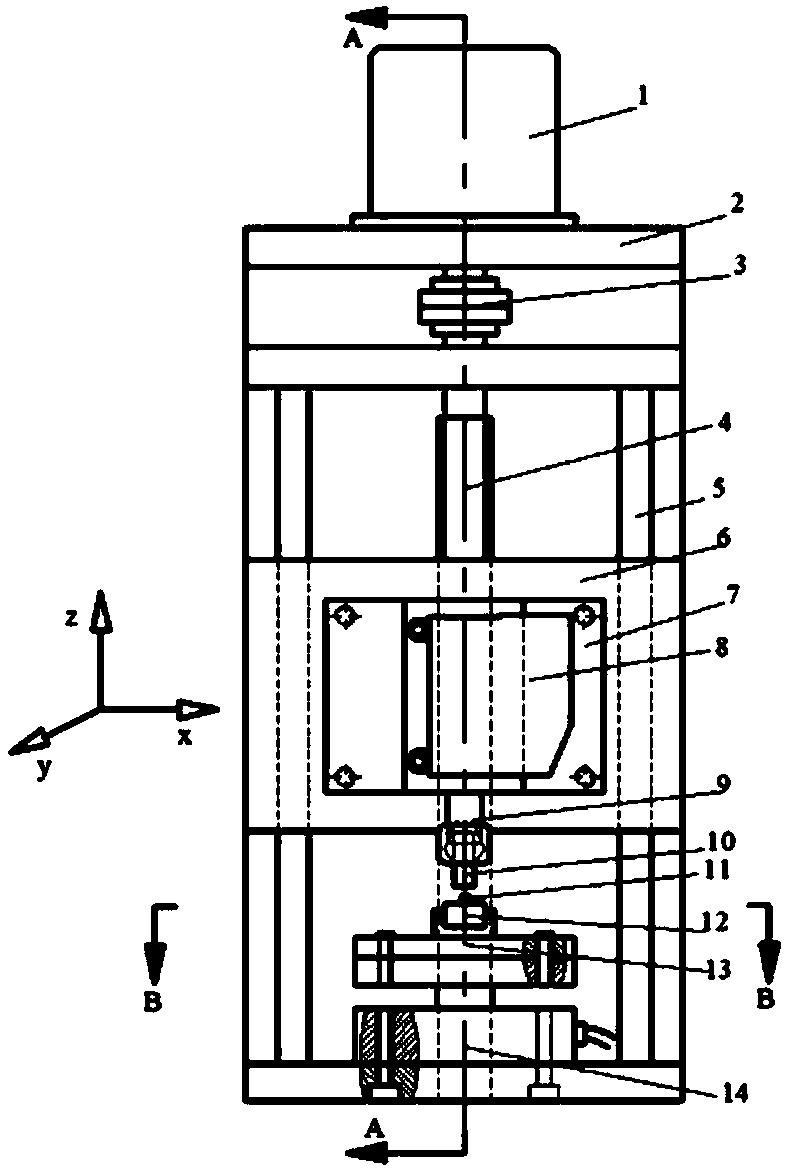

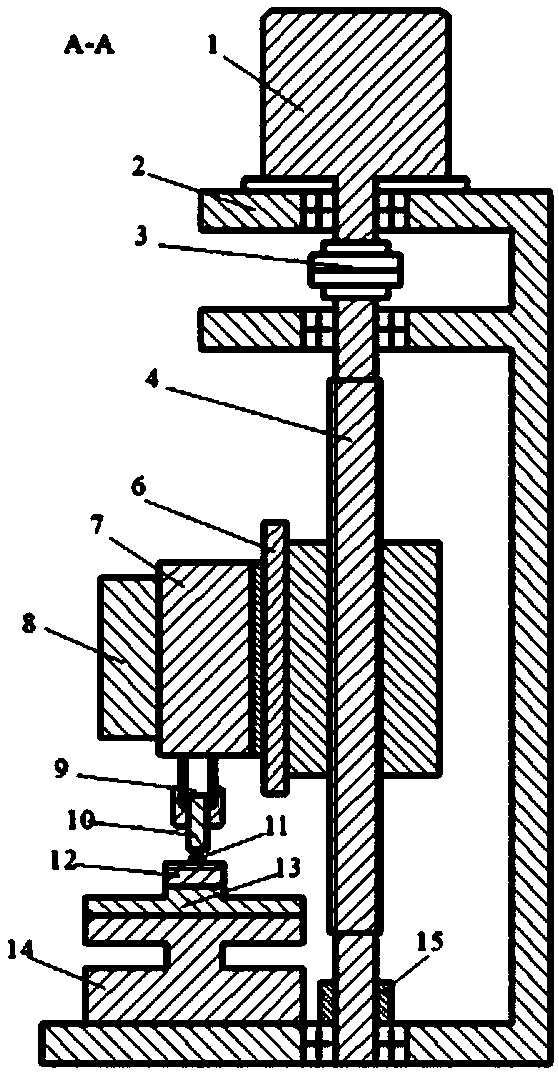

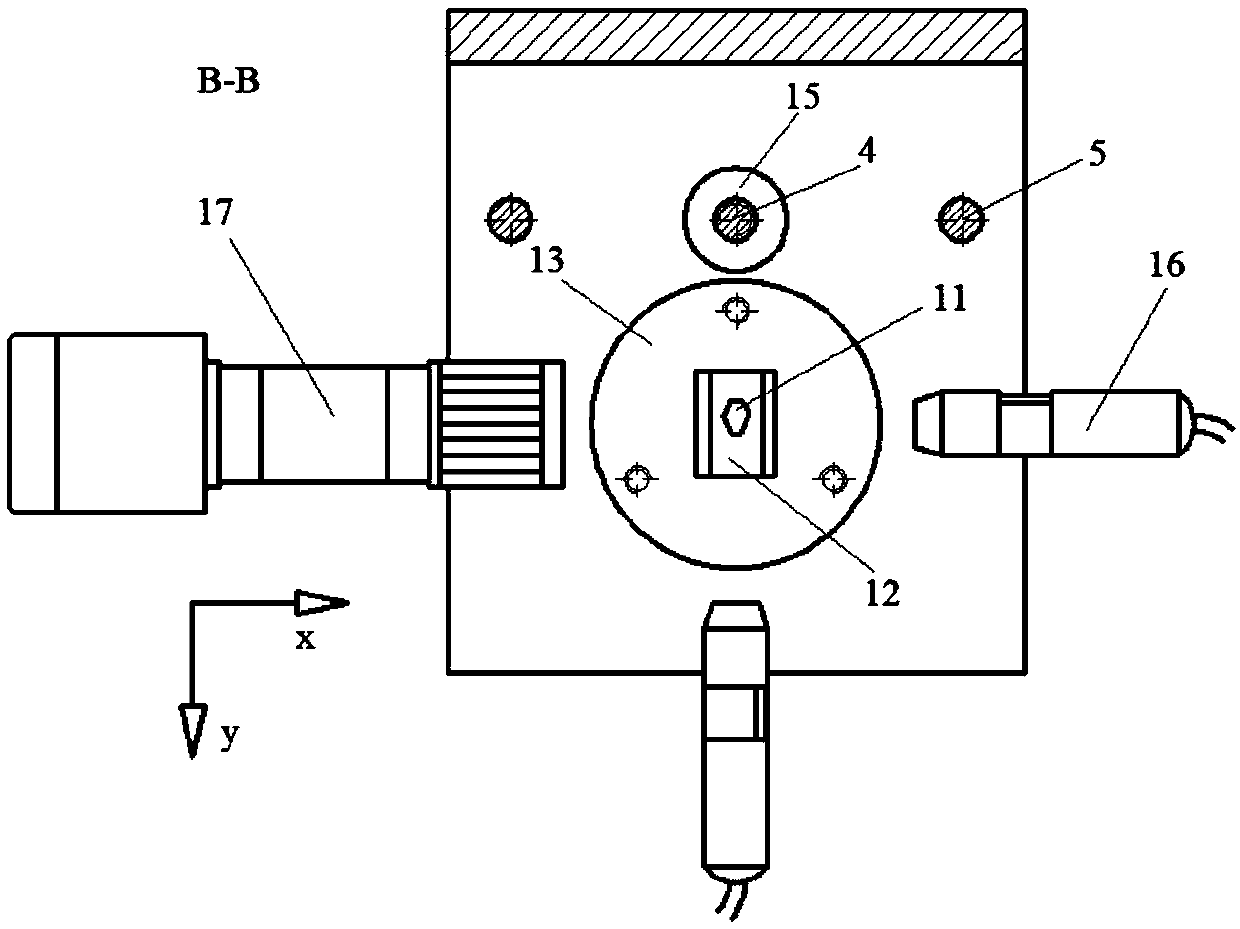

[0027] figure 1 , figure 2 and image 3 The specific structure of the device of the present invention is shown together, the drive motor 1 arranged on the frame 2 is linked with the rotating screw 4 through the shaft coupling 3 to drive the sliding table 6 to move up and down along the guide post 5 to form a linear pressure applying mechanism; The head 10 is fixed by the collet 9 arranged on the driving slide 6, and cooperates with the anvil 12 to form a normal load on the microparticle sample 11; a pressure sensor 13 is arranged under the anvil; The encoder 15, the driving slide 6 is provided with a laser displacement sensor 8 for monitoring the vertical displacement of the drive slide and the guide column; the monitoring signals of the encoder 15, the laser displacement sensor 8 and the pressure sensor 14 constitute the signal acquisition system of the experimental device ; The portable microscope 16 and the high-speed microscopic camera 17 placed near the cutting board c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com