Method for non-destructive testing of millimeter wave BGA packaging assembly

A technology of packaging components and non-destructive testing, which is applied in the microwave field to achieve the effects of improved reliability, simple structure, and high design flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

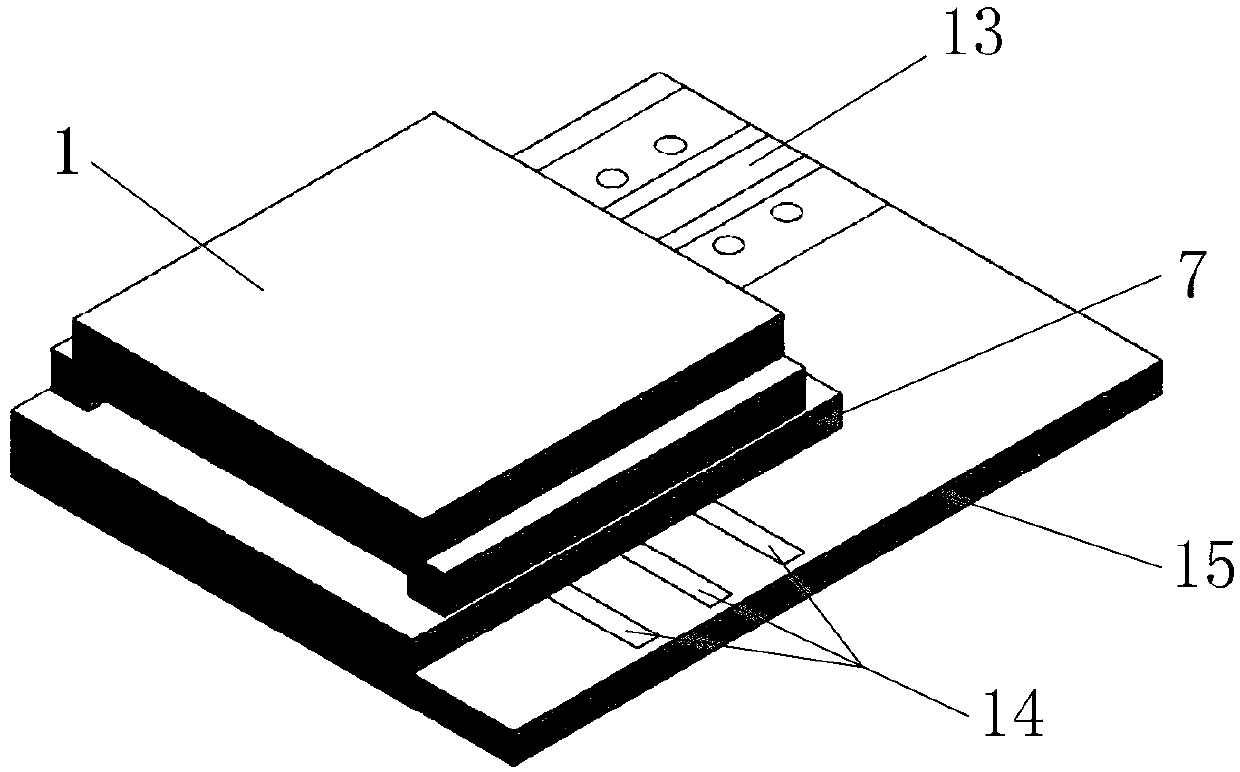

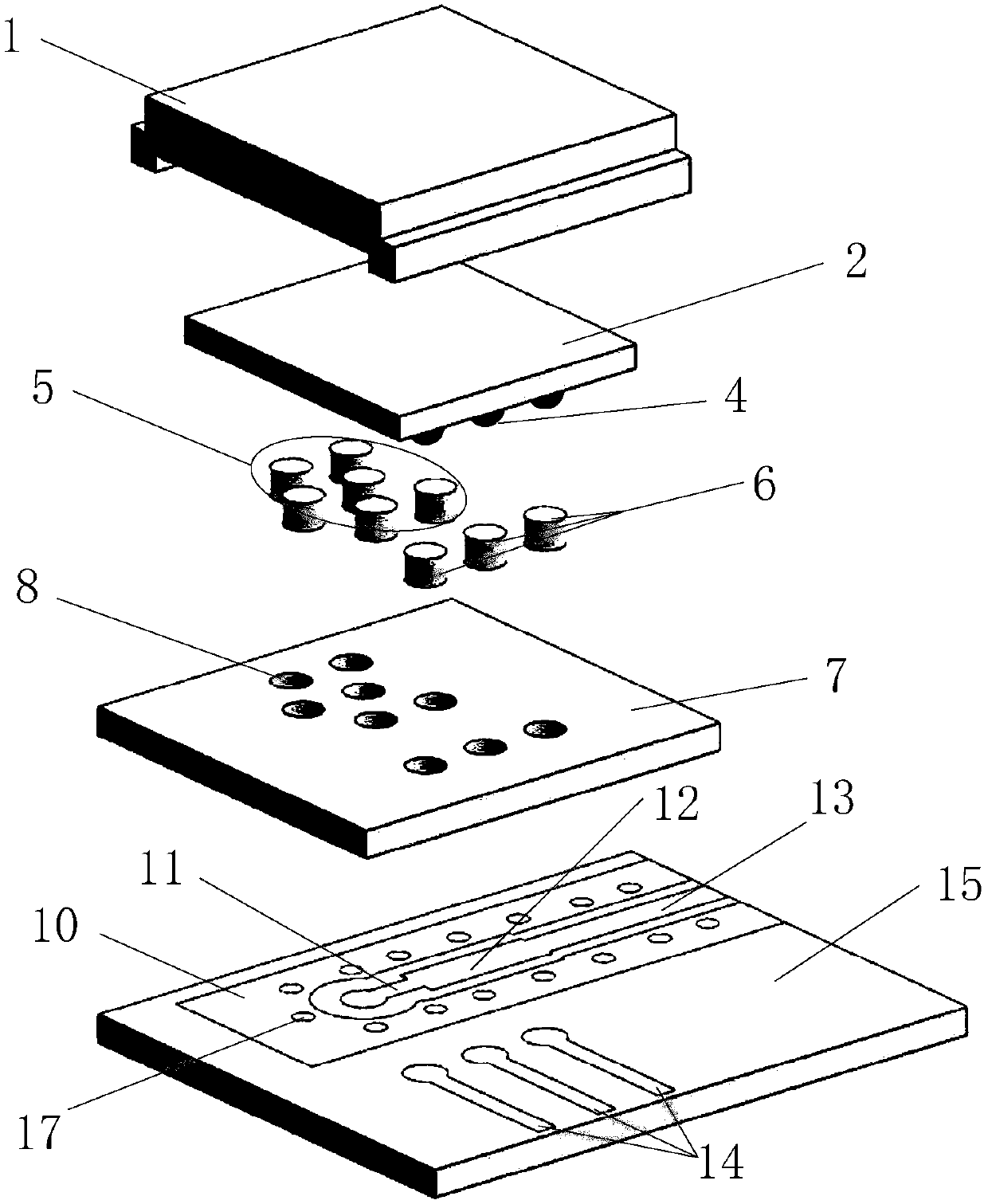

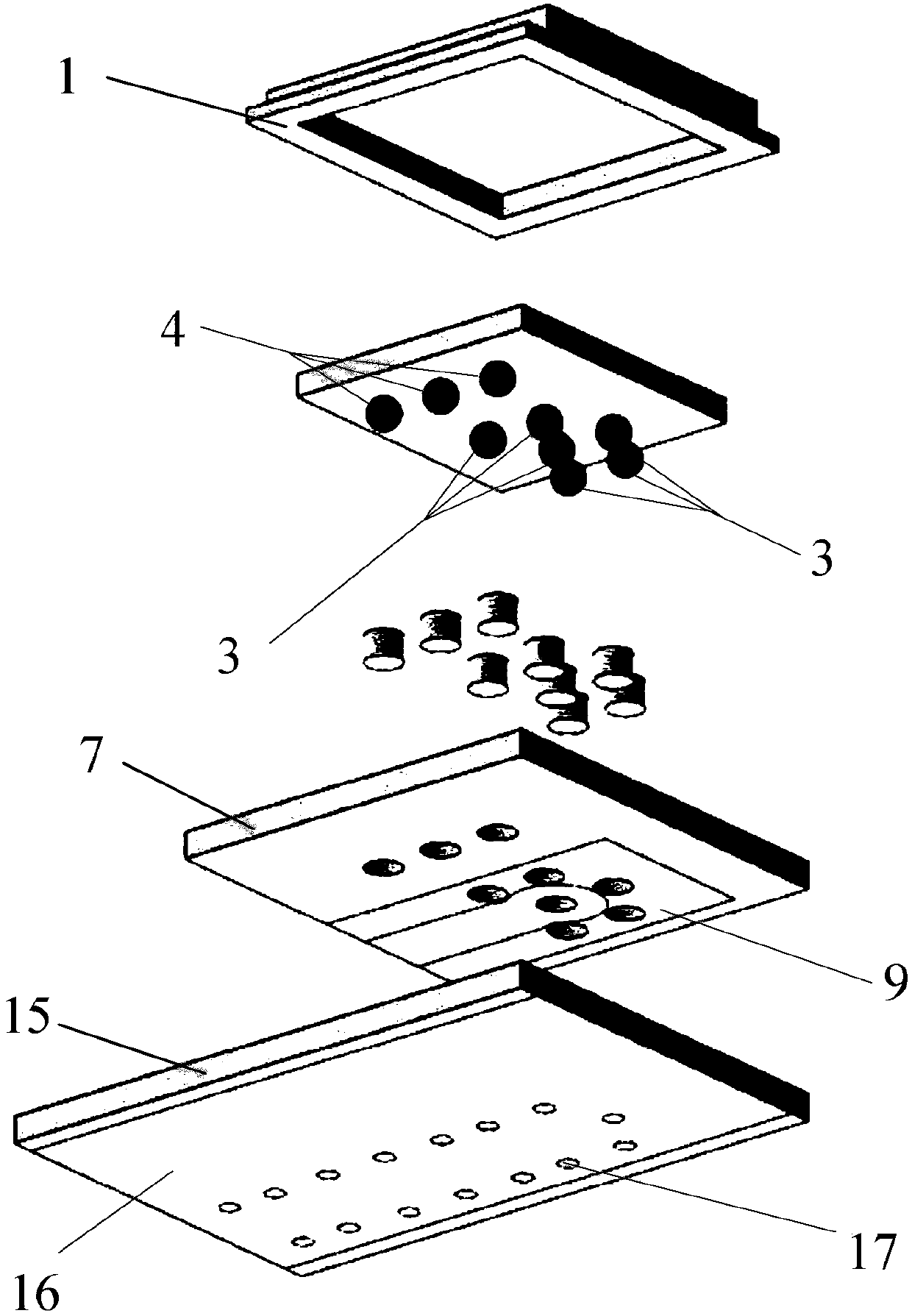

[0017] refer to Figure 1-Figure 3 . According to the present invention, on the front copper-clad surface of the second dielectric substrate 15, a ground copper surface 10 corresponding upward to the high-frequency solder ball 3 on the BGA package assembly 2 and a band circle orthogonal to it and corresponding to the low-frequency solder ball 4 are etched. The finger-shaped low-frequency transfer line 14 of the chip, and the high-impedance matching line 11 with a disc and the low-impedance matching line 12 connected to its extension are made on the long direction of the ground copper surface 10, and the low-impedance matching line 12 is connected with the low-impedance The coplanar transmission line 13 connected to the terminal of the matching line 12, the back of the second dielectric substrate 15 is covered with copper to form a large-area lower ground copper surface 16, and the ground copper surface 10 and the large-area lower ground copper surface are connected by U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com