Battery module

A technology for battery modules and single cells, which is applied to batteries, battery pack components, small-sized batteries/battery packs, etc., can solve the problems of multiple weights, reduce the energy density of battery packs, and high cost of battery packs. The effect of manufacturing cost, overall mass reduction, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

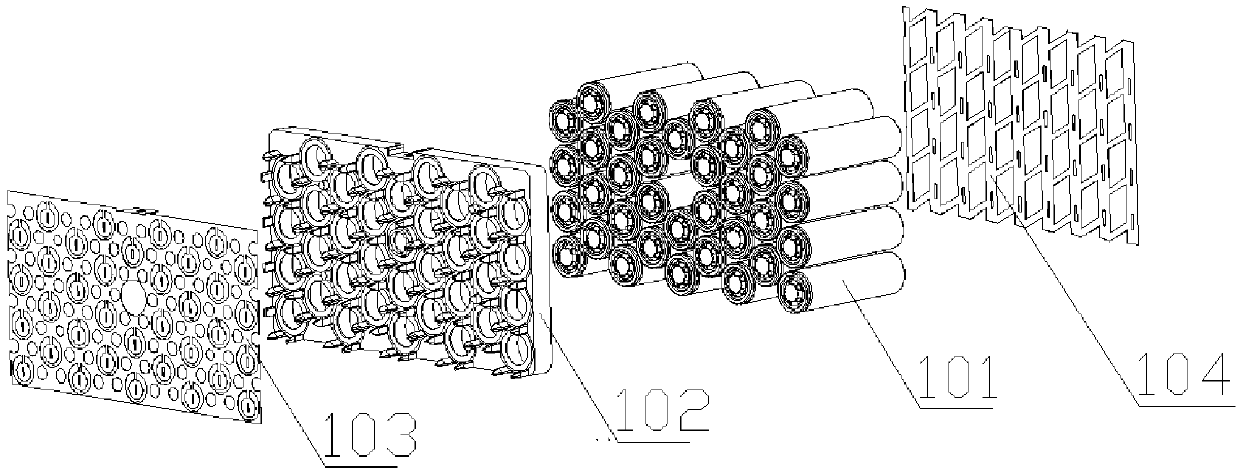

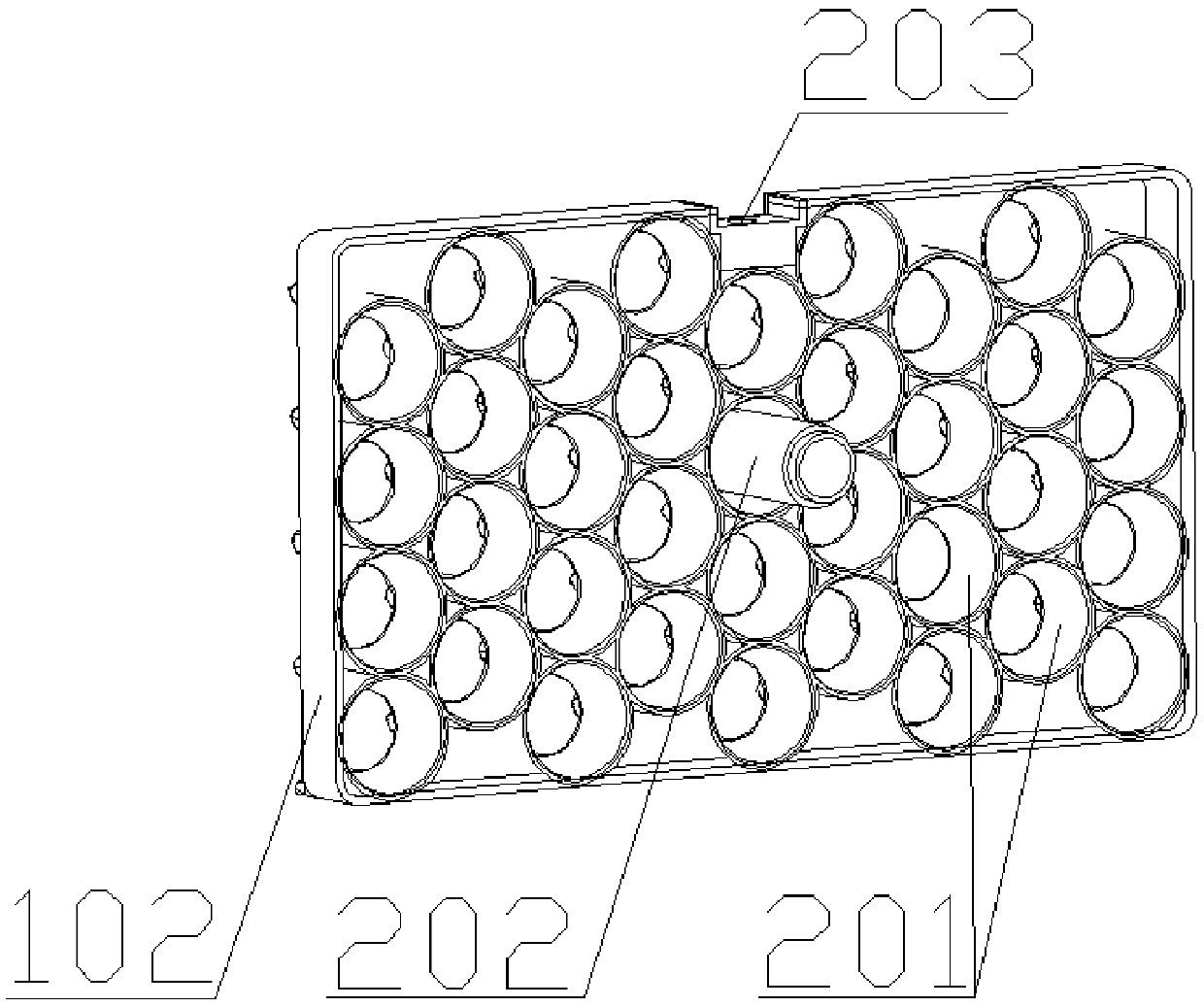

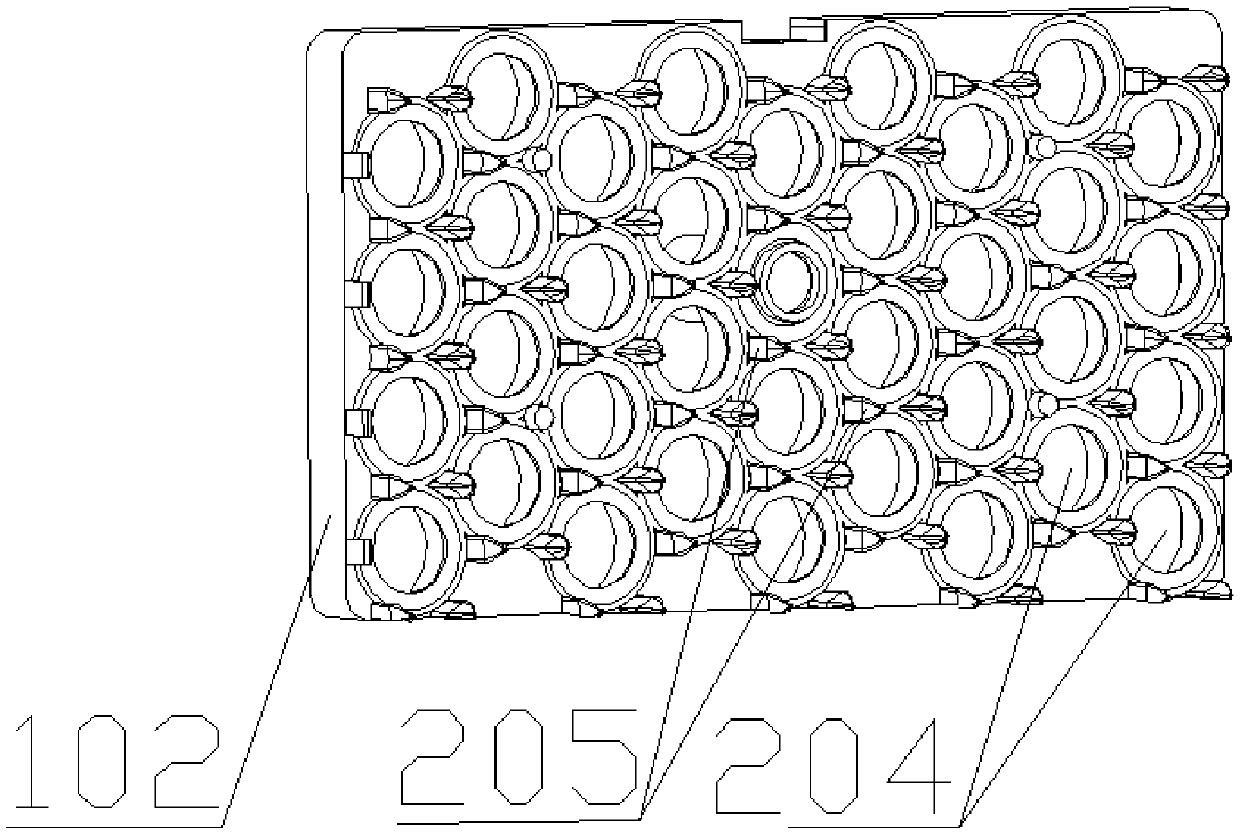

[0026] The numbers in the figure, the number 101 represents the single battery, the number 102 represents the cell fixing plate, the number 103 represents the positive electrode bus piece, the number 104 represents the negative electrode bus piece, the number 105 represents the battery module one, the number 106 represents the battery module two, and the number 201 represents a honeycomb unit, 202 represents a guide post hole, 203 represents a pre-embedded nut hole, 204 represents a through hole, 205 represents a support column, 206 represents a substructure, 207 represents an upper structure, and 208 represents a welding claw. Reference numeral 209 denotes a sampling hole.

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and technical solutions, and the implementation of the present invention will be described in detail through preferred embodiments, but the implementation of the present invention is not lim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com