Titanium mesh implant with personalized alveolar bone augmentation generated by three-dimensional printing technology

A three-dimensional printing, alveolar bone technology, applied in the medical field, can solve the problems of inability to accurately predict the height and width of the alveolar bone recovery, difficult to fit the jaw surface closely, and long operation time, so as to shorten the operation time and reduce the sticking time. Accurate fit and avoid unpredictable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

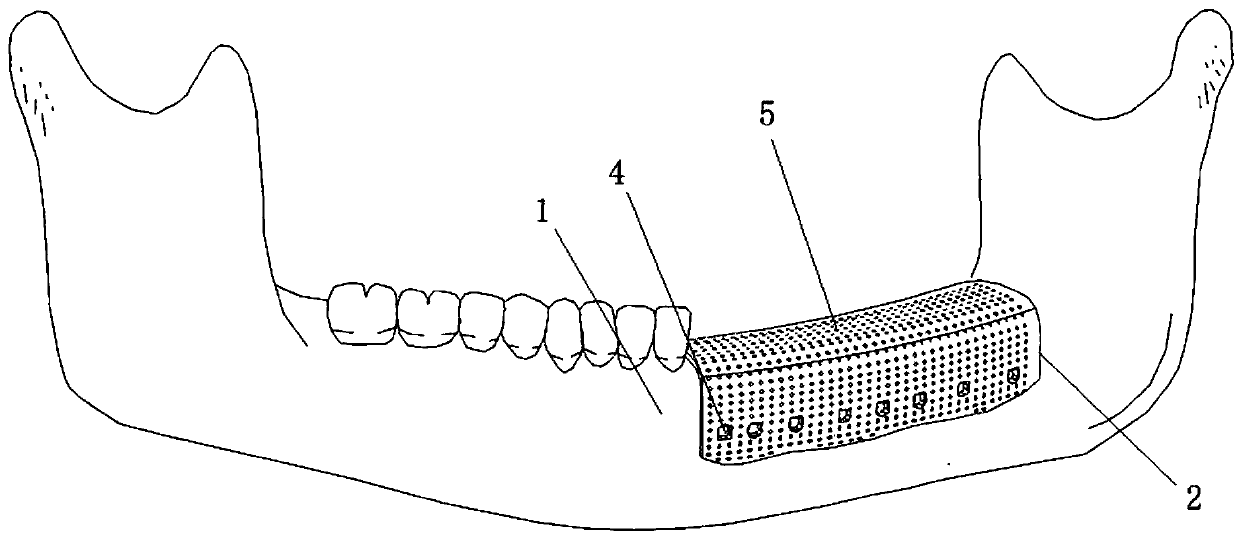

[0025] First, preoperative surgical planning. The patient takes a CT scan in the DICOMS format, imports the CT data into the design software NobelClinician for 3D reconstruction, and depicts the important anatomical structures respectively. After avoiding damage, the dental implant is placed virtually, and the crown restoration is completed to determine the best restoration effect. Based on the implant restoration plan and treatment principles, the optimal jaw reconstruction effect after maxillary bone augmentation treatment was simulated, and the surgical plan was exported as an STL format file.

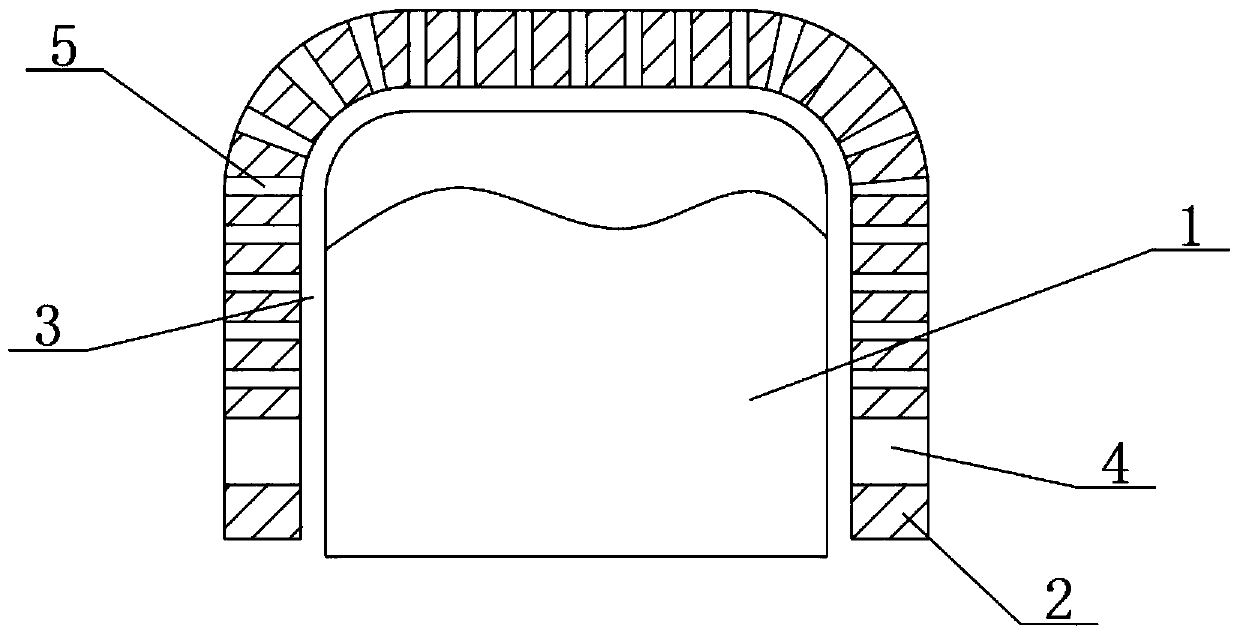

[0026] Then, the inner design of the main body of the titanium mesh. In the Geomagicstudio2013 software, according to the reconstruction effect of the best alveolar bone 1, a personalized titanium mesh main body 2 is designed. The thickness of the titanium mesh main body 2 is 0.8-1mm; there are many mesh holes scattered on the titanium mesh main body 2, and the aperture size is 2mm;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com