Light and thin flawless foundation liquid and preparing method thereof

A technology of blemish powder and primer, applied in body powder, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of heavy powder feeling, sticky texture, unnatural makeup application, etc. Thin and spreadable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

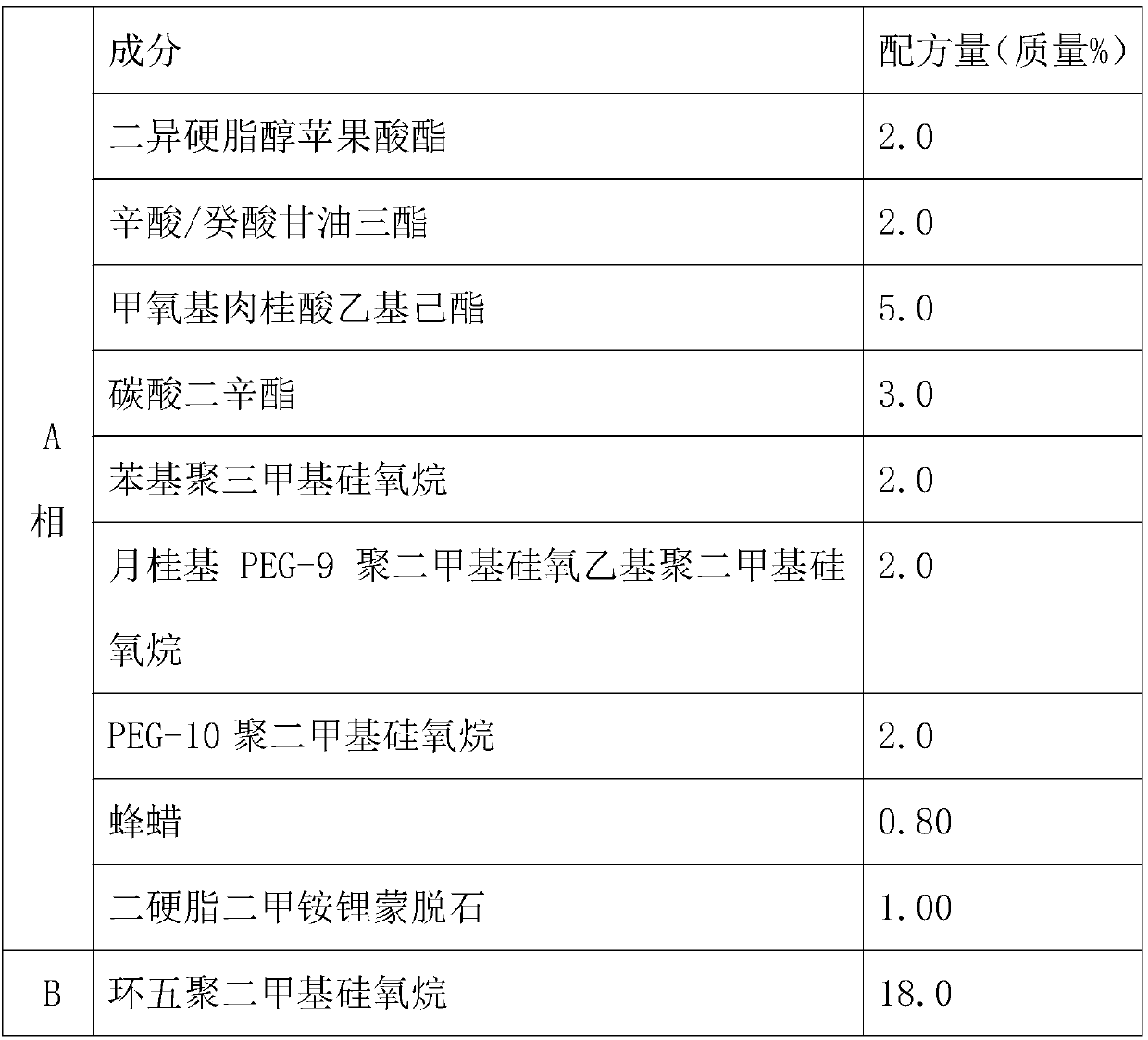

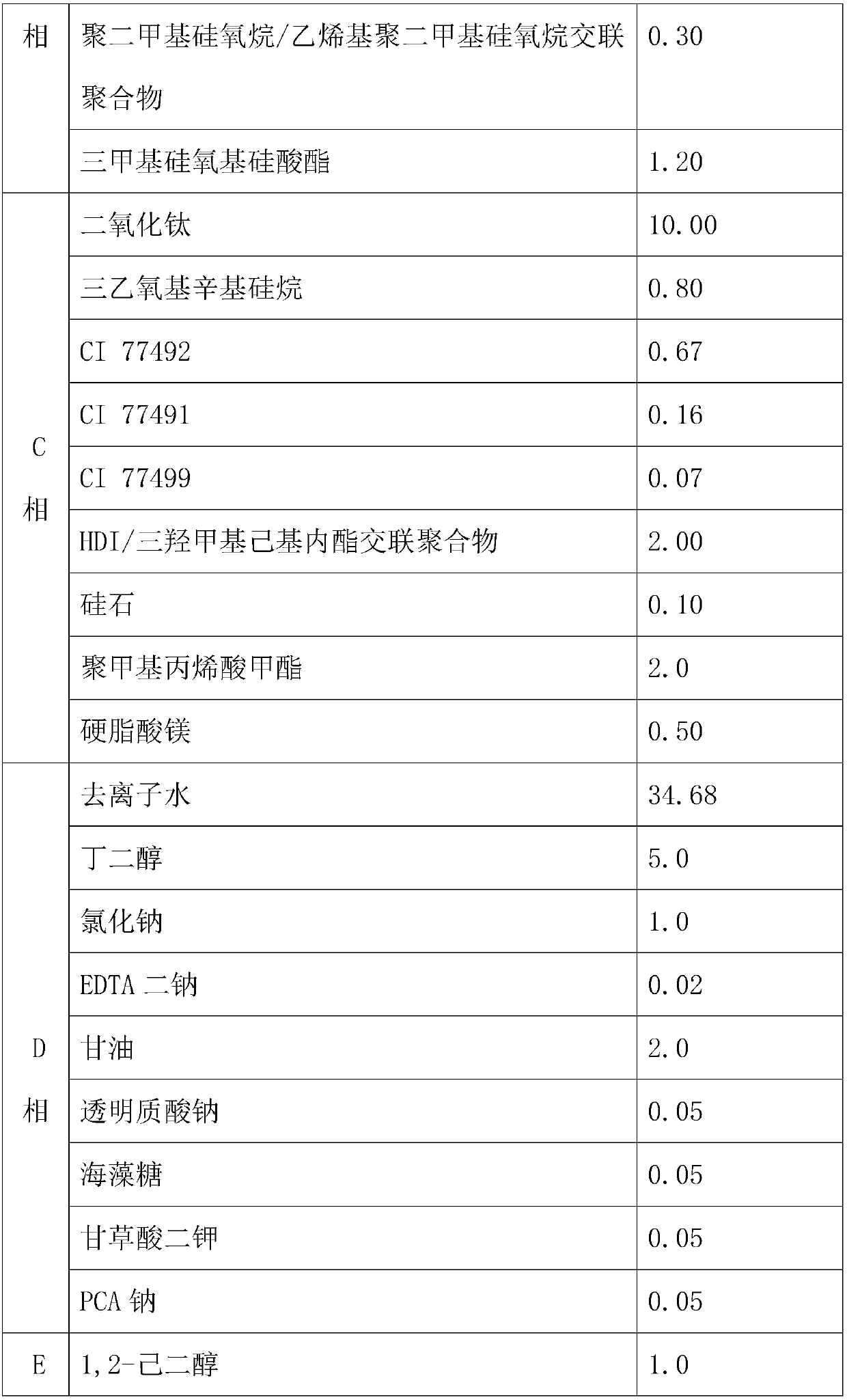

[0018] Example 1: A light and flawless liquid foundation

[0019] The formula is shown in Table 1.

[0020] Table 1

[0021]

[0022]

[0023]

[0024] A kind of frivolous flawless liquid foundation described in the present embodiment is prepared through the following steps:

[0025] (1) Pre-mix and disperse phase B evenly;

[0026] (2) Disperse item C evenly with a powder homogeneous mixer in advance;

[0027] (3) Add phase D to the water phase pot in turn, stir and heat up to 80-85°C, completely dissolve and evenly;

[0028] (4) Add the components of phase A into the emulsification pot in turn, stir and heat up to 80-85°C, and melt completely; add pre-dispersed phase C, stir evenly, heat up to 80-85°C, add pre- The dispersed phase B is stirred evenly, the emulsification pot is evacuated (-0.05MPa), and the material in the water phase pot is slowly drawn into the emulsification pot through the filter screen by negative pressure to emulsify, and the homogenization...

Embodiment 2

[0032] Example 2: A light and flawless liquid foundation

[0033] The formula is shown in Table 2.

[0034] Table 2

[0035]

[0036]

[0037]

Embodiment 3

[0038] Example 3: A light and flawless liquid foundation

[0039] The formula is shown in Table 3

[0040] table 3

[0041]

[0042]

[0043]

[0044] A kind of frivolous and flawless liquid foundation described in embodiment 2 and embodiment 3 is prepared through the following steps:

[0045] (1) Pre-mix and disperse phase B evenly;

[0046] (2) Disperse item C evenly with a powder homogeneous mixer in advance;

[0047] (3) Add phase D to the water phase pot in turn, stir and heat up to 80-85°C, completely dissolve and evenly;

[0048] (4) Add the components of phase A into the emulsification pot in turn, stir and heat up to 80-85°C, and melt completely; add pre-dispersed phase C, stir evenly, heat up to 80-85°C, add pre- The dispersed phase B is stirred evenly, the emulsification pot is evacuated (-0.05MPa), and the material in the water phase pot is slowly drawn into the emulsification pot through the filter screen by negative pressure to emulsify, and the homo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com