Flame-retardant ACS (acrylonitrile-vinyl chloride-styrene) composite material

A technology of composite materials and flame retardants, which is applied in the field of flame-retardant ACS composite materials, can solve the problems of low flame-retardant performance, and achieve the effects of improving flame retardancy, impact resistance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

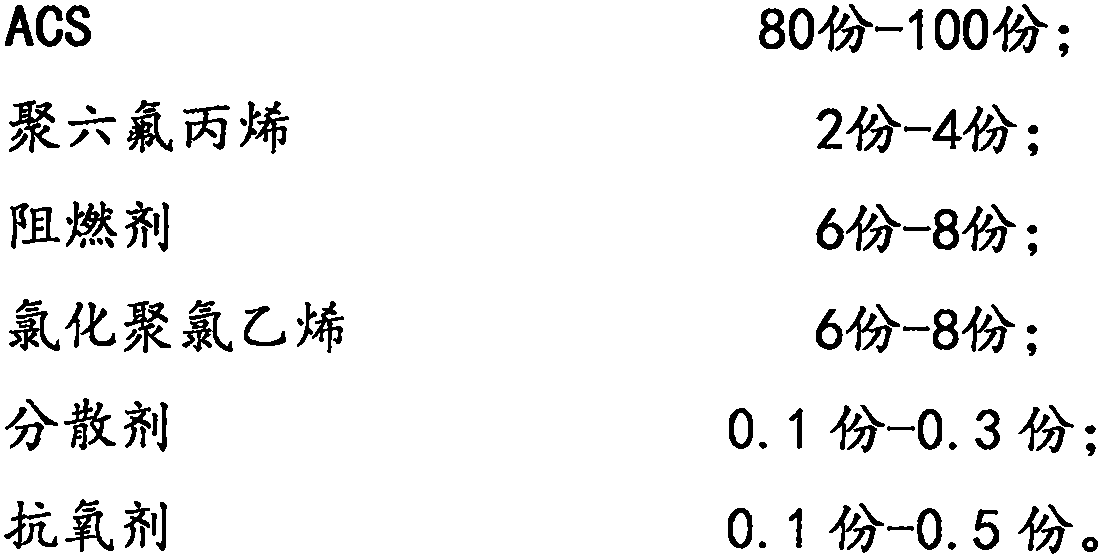

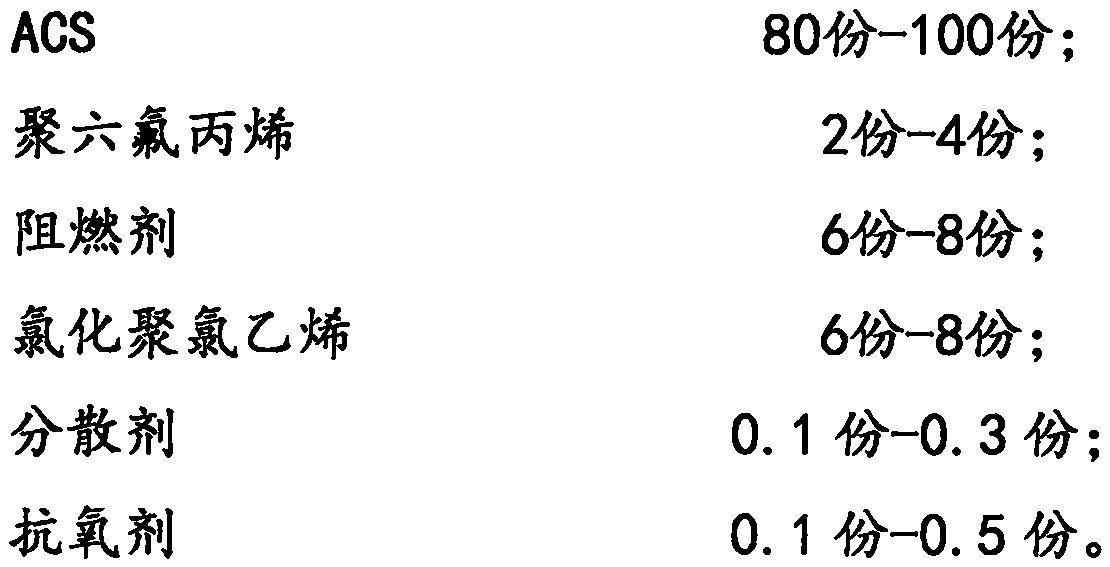

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 80 parts of ACS, 2 parts of polyhexafluoropropylene, 6 parts of WR03, 6 parts of chlorinated polyvinyl chloride, 0.1 part of E525, 0.1 part of Irganox168 and mix them evenly to obtain a mixture;

[0023] (2) Extrude and granulate the mixture obtained in step (1) to obtain ACS composite material P1.

[0024] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 200°C, the temperature of the second zone is 240°C, the temperature of the third zone is 240°C, the temperature of the fourth zone is 240°C, the temperature of the fifth zone is 240°C, and the temperature of the sixth zone is 240°C. The head temperature is 240°C, and the screw speed is 200r / min.

Embodiment 2

[0026] (1) Weigh 100 parts of ACS, 4 parts of polyhexafluoropropylene, 8 parts of WR03, 8 parts of chlorinated polyvinyl chloride, 0.3 parts of E525, 0.1 parts of Irganox168, 0.2 parts of Irganox1010, 0.2 parts of Irganox1330 and mix them evenly to obtain a mixed material;

[0027] (2) Extruding and granulating the mixture obtained in the step (1) to obtain the ACS composite material P2.

[0028] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 220°C, the temperature of the second zone is 260°C, the temperature of the third zone is 260°C, the temperature of the fourth zone is 260°C, the temperature of the fifth zone is 260°C, the temperature of the sixth zone is 260°C, The head temperature is 260°C, and the screw speed is 280r / min.

Embodiment 3

[0030] (1) Weigh 90 parts of ACS, 3 parts of polyhexafluoropropylene, 7 parts of WR03, 7 parts of chlorinated polyvinyl chloride, 0.2 part of E525, 0.1 part of Irganox168, 0.2 part of Irganox1010 and mix them evenly to obtain a mixture;

[0031] (2) Extrude and granulate the mixture obtained in step (1) to obtain ACS composite material P3.

[0032] Among them, the temperature and screw speed of each zone of the twin-screw extruder are respectively: the temperature of the first zone is 210°C, the temperature of the second zone is 250°C, the temperature of the third zone is 250°C, the temperature of the fourth zone is 250°C, the temperature of the fifth zone is 250°C, and the temperature of the sixth zone is 250°C. The head temperature is 250°C; the screw speed is 240r / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com