Shock wave dust cleaning gun

A shock wave ash cleaning gun and ash cleaning technology are applied in the fields of solid residue removal, combustion product treatment, and combustion methods. The weight can be disassembled and moved to improve the cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

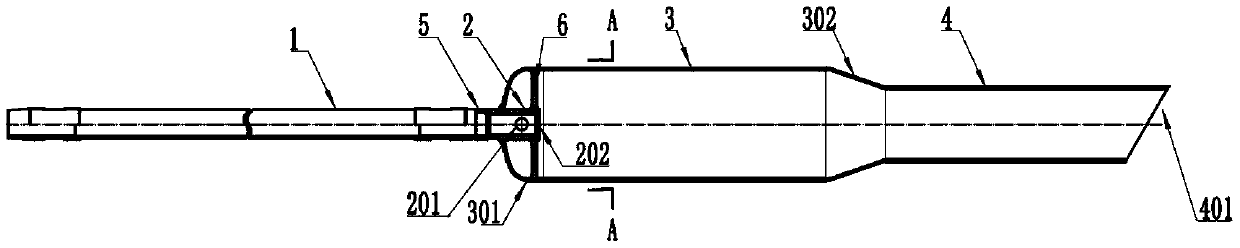

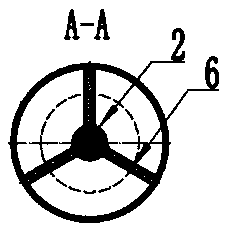

[0035] Such as figure 1 , figure 2 The shock wave cleaning gun shown includes a guide pipe 1 and its port 2, an energy storage tank 3 and a release pipe 4. The guide pipe 1 is two galvanized pipes with a diameter of 2 meters and a diameter of DN32mm through threaded pipe collars. The two ends of the guide pipe 1 are threaded connection structures; the port 2 is made of a seamless steel pipe with a length of 120 mm and a diameter of DN32 mm, and one end of the port 2 is welded and sealed with a carbon steel blocking plate 202. The other end of the port 2 is a threaded interface, and four air guide holes 201 of Φ15 mm evenly distributed are opened on the side wall of the port 2 40 mm away from the blocking plate. The welded head 301 is a seamless welded head of DN125mm, a through hole of Φ40mm is opened in the center of the welded head 301, and three mutual angles of 120 degrees, The steel support frame 6 of Φ12mm protrudes the port 2 from the through hole of Φ40mm, and the s...

Embodiment 2

[0037] Such as figure 1 , figure 2 The shock wave cleaning gun shown includes a guide pipe 1 and its port 2, an energy storage tank 3 and a release pipe 4. The guide pipe 1 is three seamless steel pipes with a length of 2 meters and a diameter of DN40mm, which are sequentially connected by threaded pipe fittings. The two ends of the guide pipe 1 are threaded connection structures; the port 2 is made of a seamless steel pipe with a length of 130mm and a diameter of DN40mm, and one end of the port 2 is sealed by welding with a carbon steel blocking plate 202. The other end of the port 2 is a pipe collar interface, and three Φ20mm evenly distributed air guide holes 201 are opened on the side wall of the port 2 45mm away from the blocking plate. The welded head 301 is a seamless welded head of DN150mm, and a through hole of Φ60mm is opened in the center of the welded head 301, and 4 pieces are welded on the pipe wall at the end of the blocking plate 202 of the port 2 with a mutu...

Embodiment 3

[0039] Such as figure 1 , figure 2 The shown shock wave cleaning gun includes a guide pipe 1 and its port 2, an energy storage tank 3 and a release pipe 4. The guide pipe 1 is a stainless steel pipe with a diameter of 3 meters and a diameter of DN50mm. The guide pipe The two ends of 1 are ferrule connection structures; the port 2 is made of stainless steel pipe with a length of 140mm and a diameter of DN50mm, one end of the port 2 is welded and sealed with a stainless steel blocking plate 202, and the other end of the port 2 is a ferrule interface , On the side wall of the port 2 50 mm away from the blocking plate, open five Φ15 mm evenly distributed air guide holes 201 . The welding head 301 is a stainless steel welding head of DN150mm, and a Φ60mm through hole is opened in the center of the welding head 301, and 6 pieces of mutual angles of 60 degrees and Φ10mm are welded on the pipe wall at the end of the blocking plate 202 of the port 2. The steel bar support frame 6, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Slope | aaaaa | aaaaa |

| The way to | aaaaa | aaaaa |

| The way to | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com