Automatic positioning packaging and attaching equipment of polaroid and production technology thereof

An automatic positioning, polarizer technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of wasting time and reducing output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

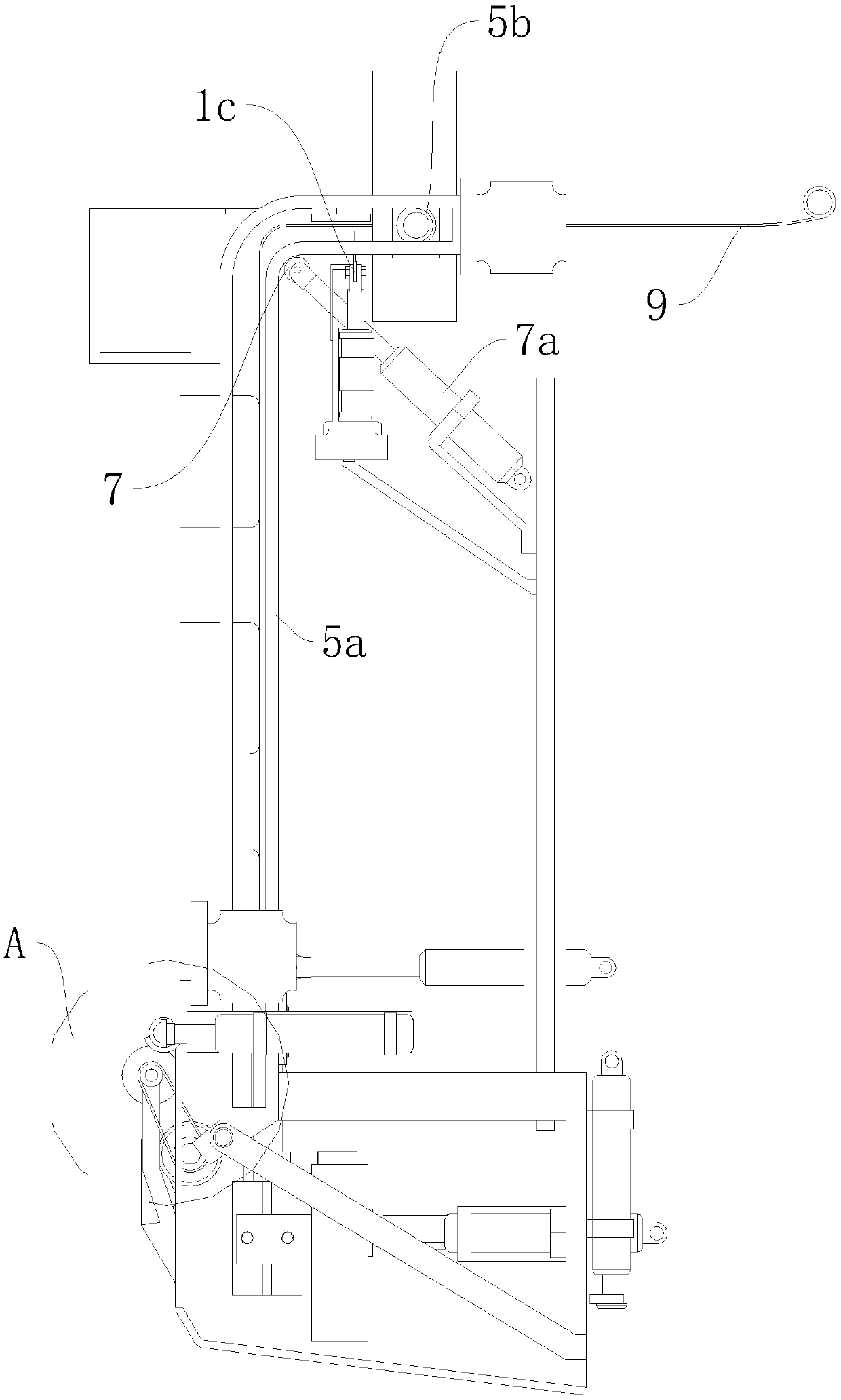

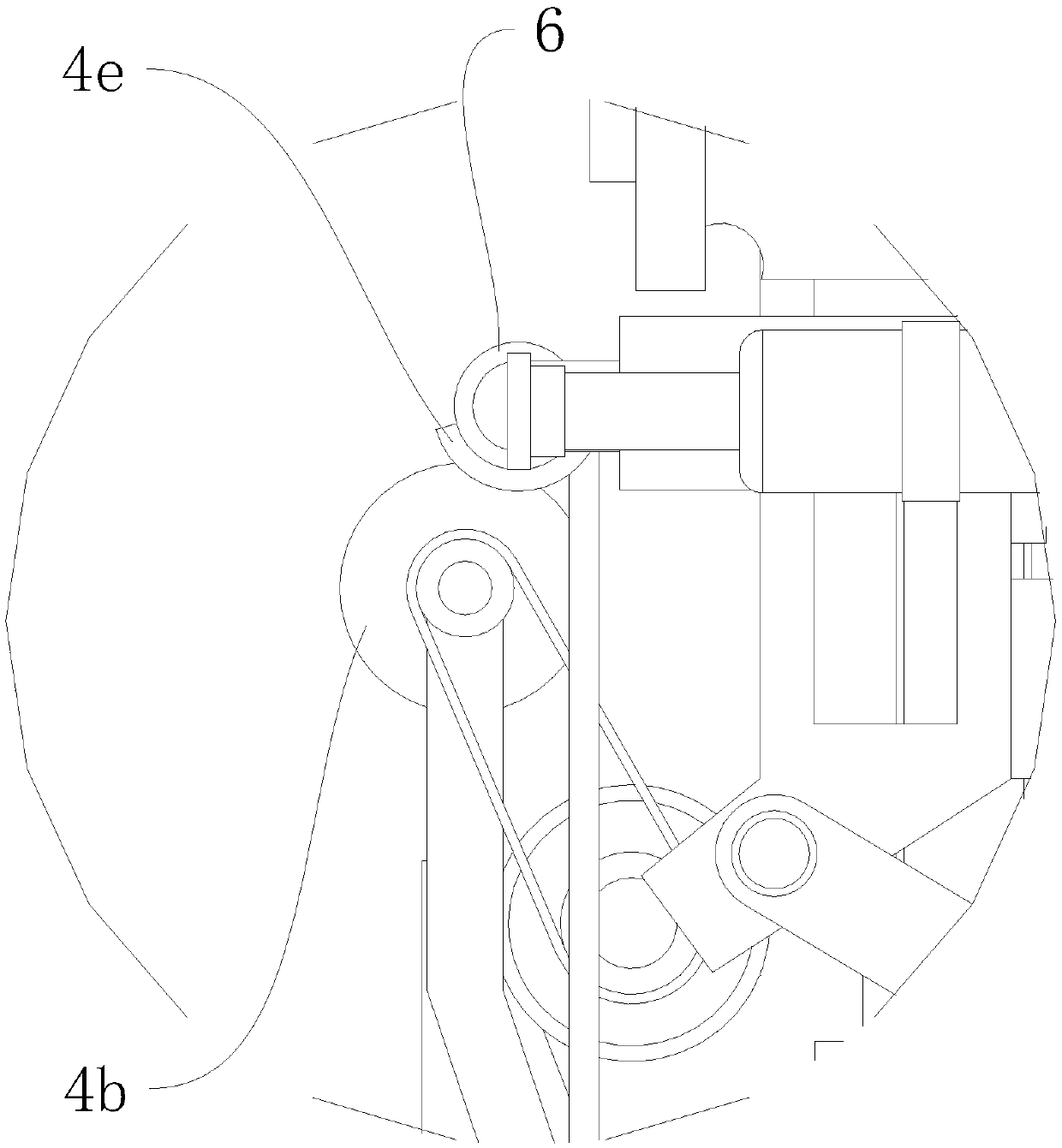

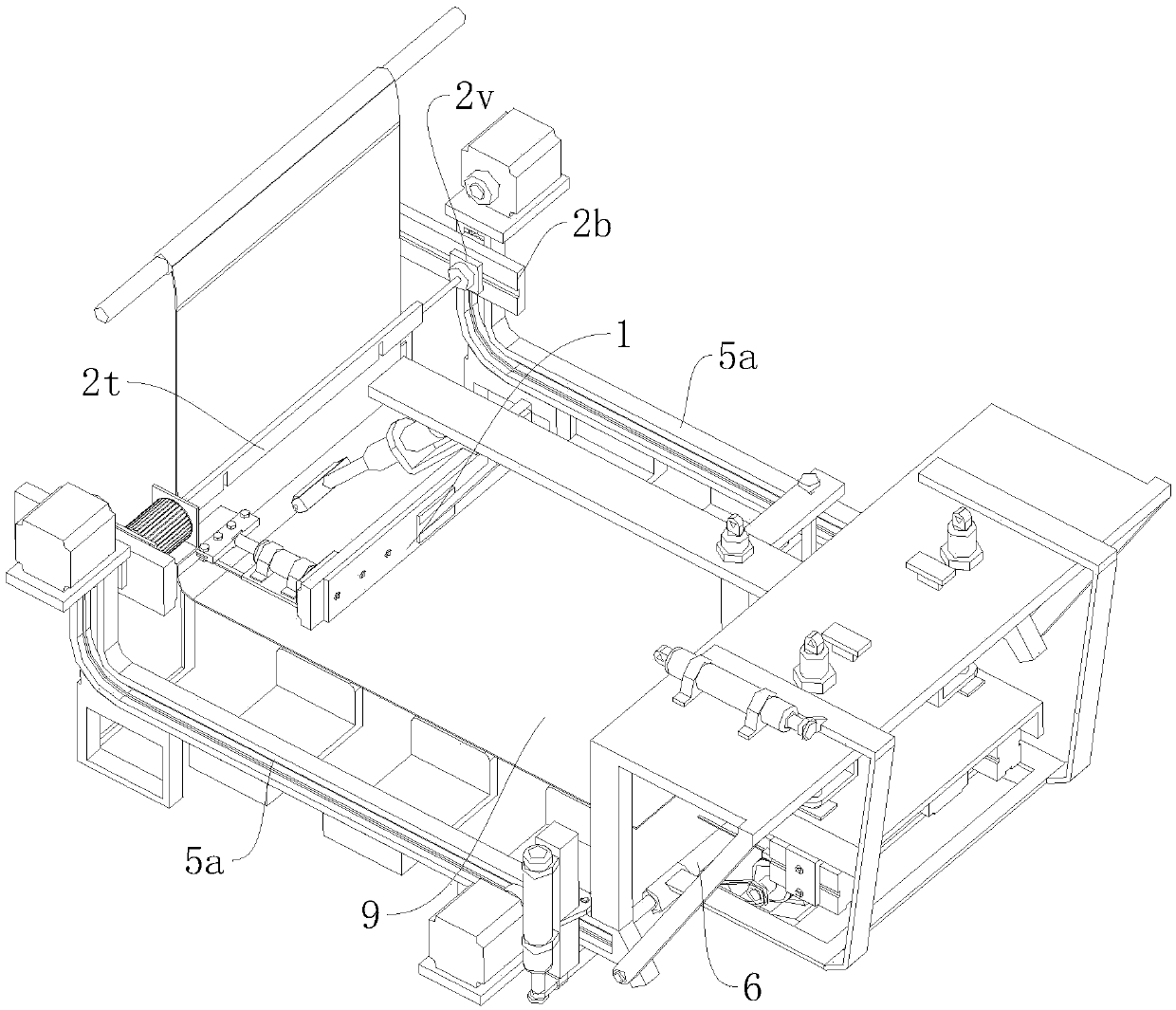

[0046] refer to Figure 1 to Figure 11 The shown automatic positioning packaging and bonding equipment for polarizers includes a body, a cutting mechanism, a traction mechanism, a winding mechanism and a film removal mechanism in the body, and the body includes two slide rails 5a close to an L-shaped structure , the slide rails 5a are arranged horizontally, and each slide rail 5a is respectively provided with a guide pulley 5b, and the traction mechanism can move along the extending direction of the slide rail 5a through the two guide pulleys 5b and is arranged between the two slide rails 5a, The winding mechanism is located at the end of the slide rail 5a, and can be vertically or horizontally movable through the linkage device. An attachment shaft 6 that can rotate around its own axis is arranged in parallel between the ends of the two slide rails 5a. The attachment shaft 6 The end of 6 is provided with an extension mechanism for driving its vertical movement, and the film r...

Embodiment 2

[0056] The production process of the automatic positioning packaging and bonding equipment for the polarizer described in the embodiment includes the following steps:

[0057] Step 1. Place the rolled polarizing film 9 on the inflatable shaft, and pull down the end of the polarizing film 9 manually for the first time until the height of the cutting plate 1b is reached, and then the pulling mechanism will unwind the rolled polarizing film 9. The end is sucked tightly, and moves toward the winding mechanism along the track direction of the slide rail 5a through the guide pulley 5b. When passing through the turning point of the slide rail 5a, the adsorption plate 2t in the traction mechanism rotates 90° to a horizontal posture by the correction motor 2a , so that the polarizing film 9 changes from a vertical pulling state to a horizontal pulling state;

[0058] Step 2: After the traction mechanism leaves the turning point of the slide rail 5a, the anti-warping member works, and m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com