A design method of a multi-channel parallel three-power combined engine

A design method and engine technology, applied in computer-aided design, calculation, special data processing applications, etc., can solve problems such as multi-channel combined power thrust traps, weak dual-mode combustion foundation, and difficulty in achieving thrust connection, and achieve an adjustable structure. Simple and reliable, compact structure, good starting performance and wide speed range performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

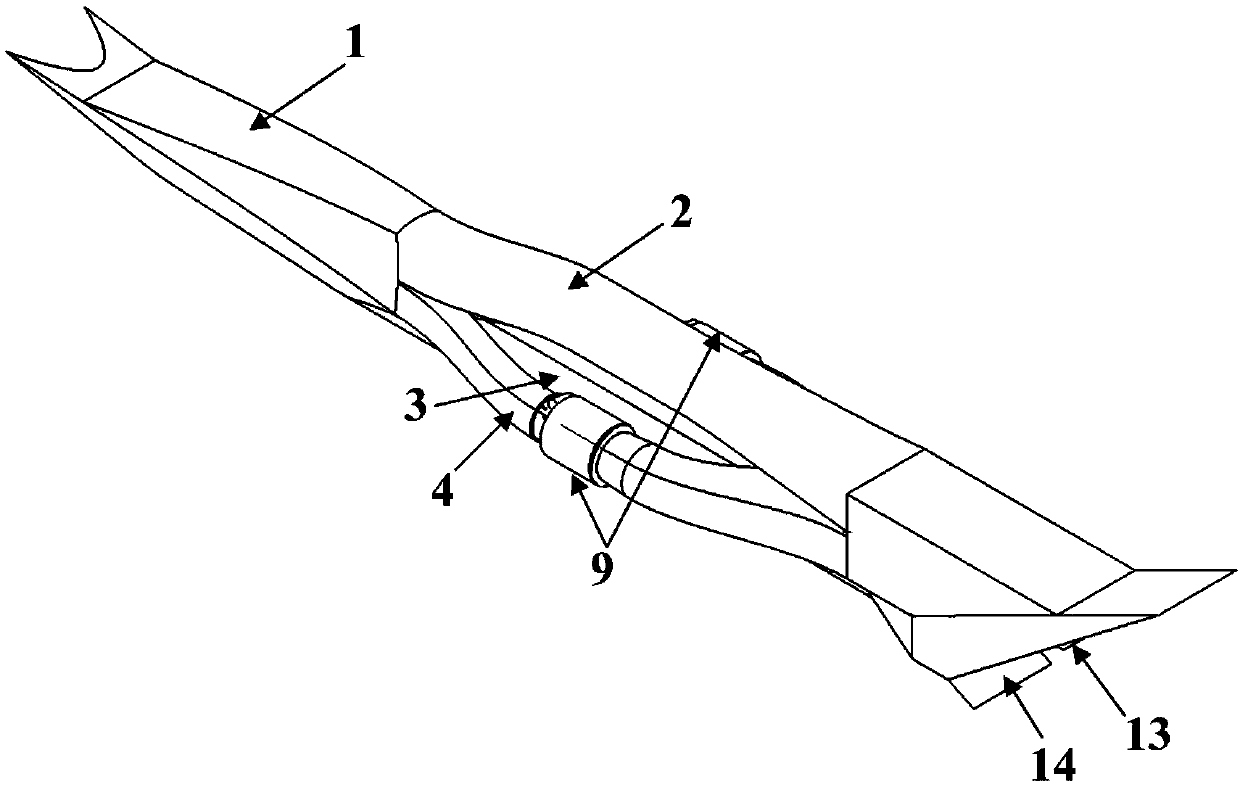

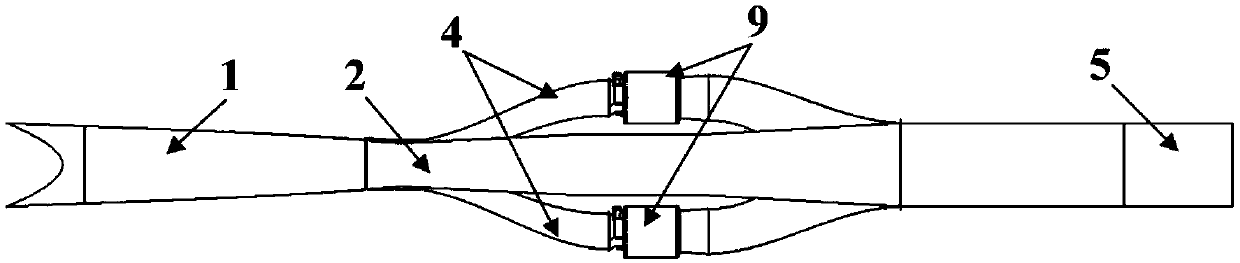

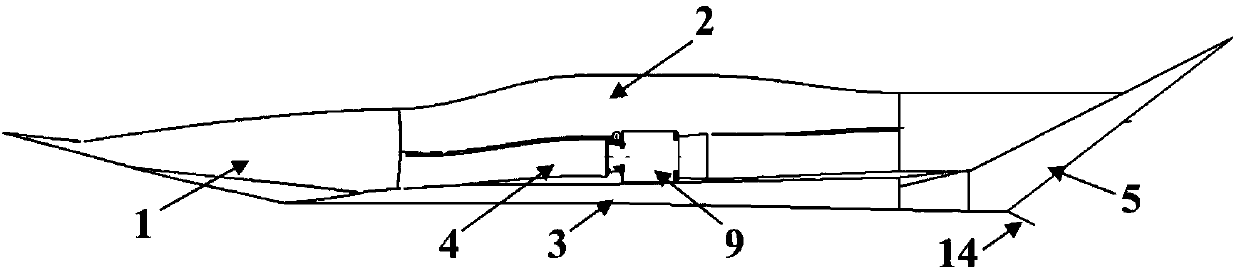

[0045] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer and clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0046] A multi-channel parallel three-power combination engine design method, comprising the following steps:

[0047] 1) Formulate the overall performance requirements according to the flight mission, design the basic flow field based on the overall performance requirements, determine the capture area of the inlet, and then obtain the three-dimensional inward turning inlet through streamline tracing in the basic flow field;

[0048] 2) Based on step 1) the outlet area of the three-dimensional internal turning inlet, calculate the inlet and outlet parameters of the superburning combustion chamber 8 according to the overall performance of the engine, and then design the superburning channel and the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com