Thick pulp sandwich seaweed process line

A sandwich seaweed and assembly line technology, which is applied in food science, food coating, application, etc., can solve the problems of low production efficiency and difficulty in ensuring quality of sandwich seaweed, so as to facilitate continuous production operations, ensure slurry uniformity, reduce The effect of scraping side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

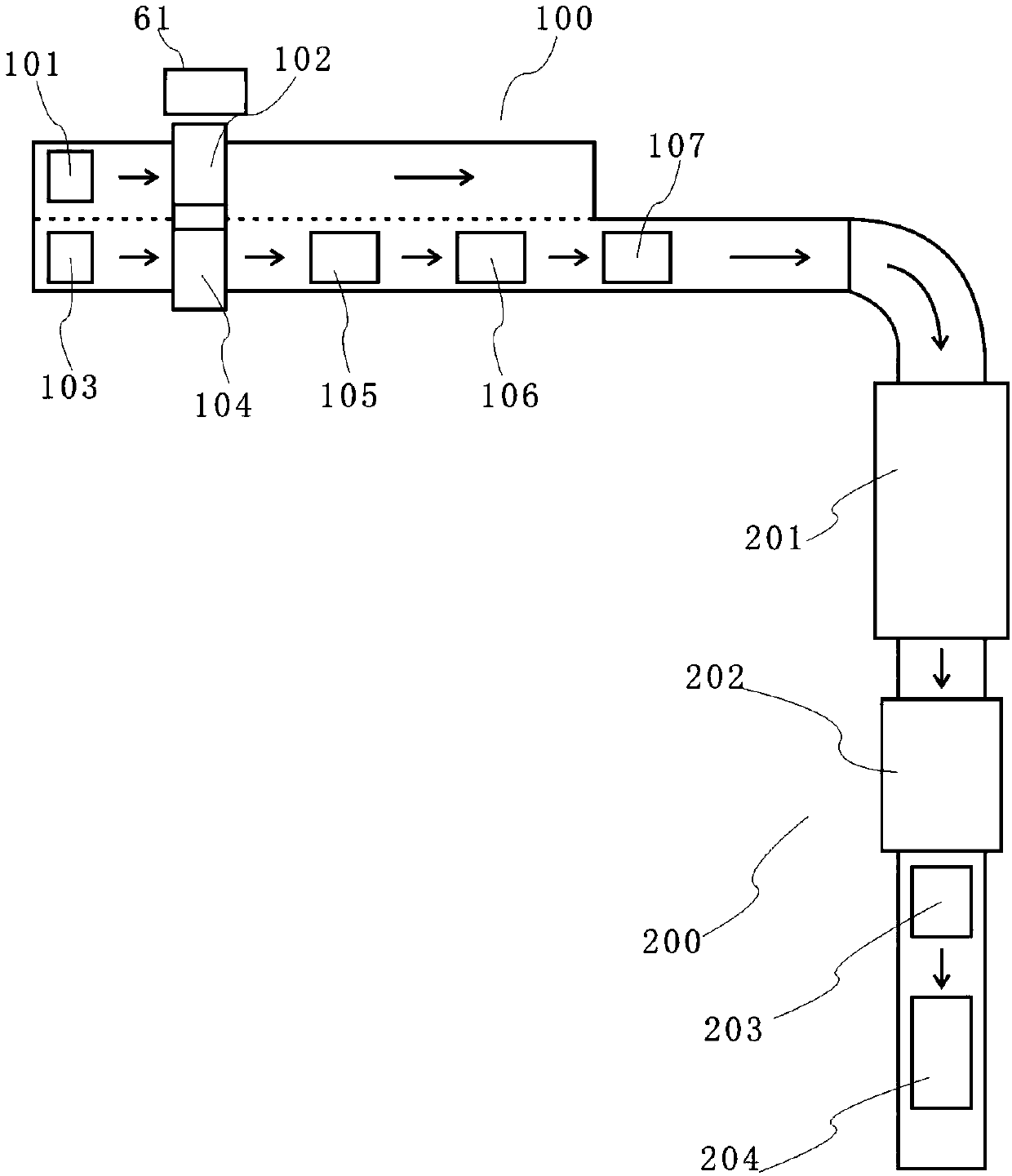

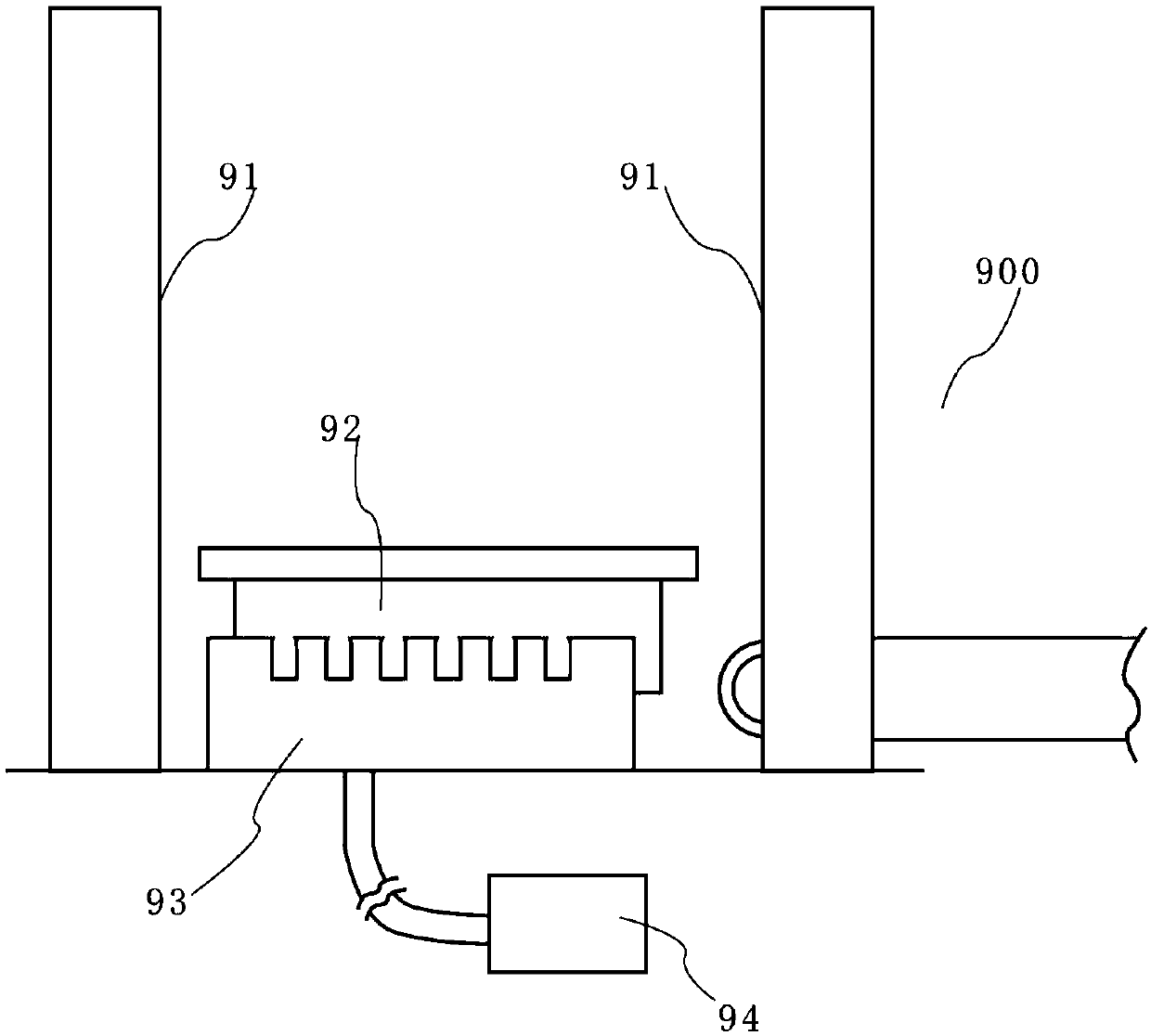

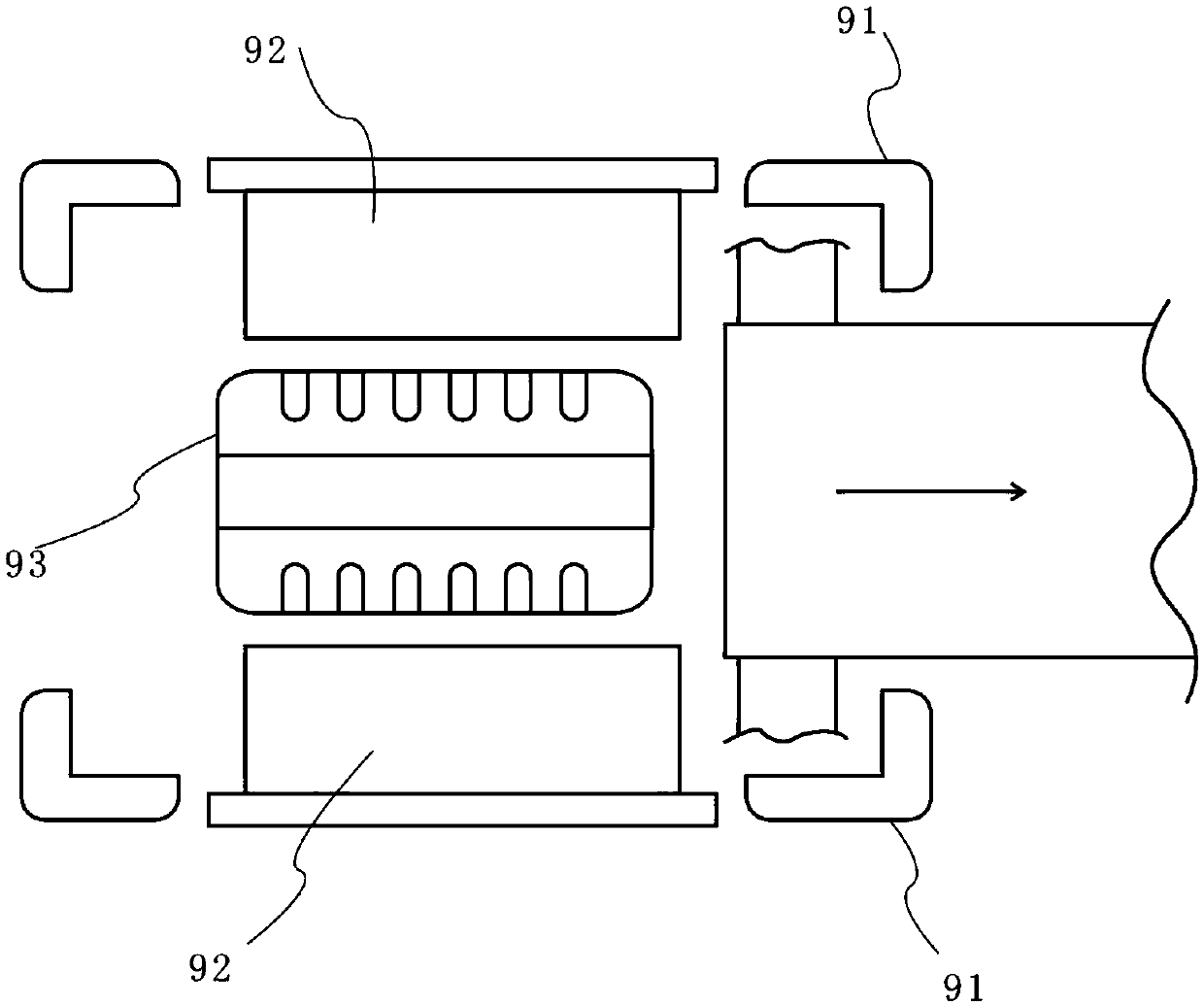

[0031] Such as Figure 1-8 As shown, the present embodiment provides a thick paste sandwich seaweed processing line, including an electric control system and a single-chip processing line 100 and a sandwich sheet processing line 200 electrically connected to the electric control system, and the electric control system includes The PLC controller for monitoring and controlling the opening and closing of each electrical component on the assembly line, preferably the PLC controller is Japan Mitsubishi FX2N.

[0032]In this embodiment, the single sheet processing line 100 includes a first conveying line and an upper sheet supply position 101, an upper sheet roller coating position 102, a lower sheet supply position 103, a lower sheet Roller coating position 104, coarse material level 105, fine material level 106 and composite position 107, the sandwich sheet processing line 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com