Thick gravy sandwiched seaweed and its processing technology

A technology of sandwich seaweed and processing technology, which is applied in the field of thick paste sandwich seaweed and its processing technology, can solve the problems of difficult quality assurance and low production efficiency of sandwich seaweed, and achieve continuous production operations, reduce side effects of scraping coating, and ensure uniformity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

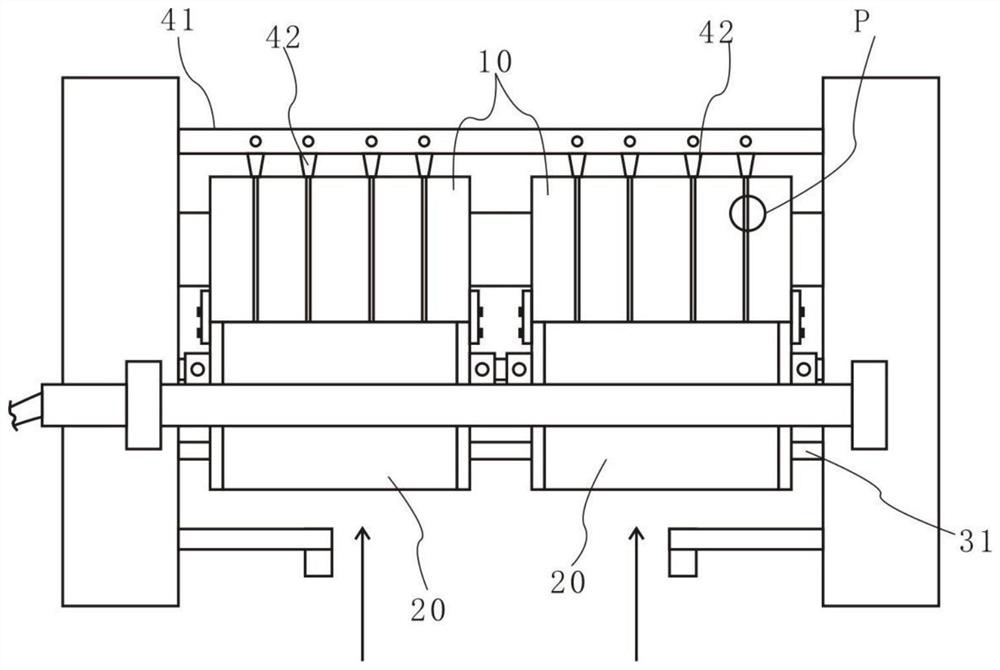

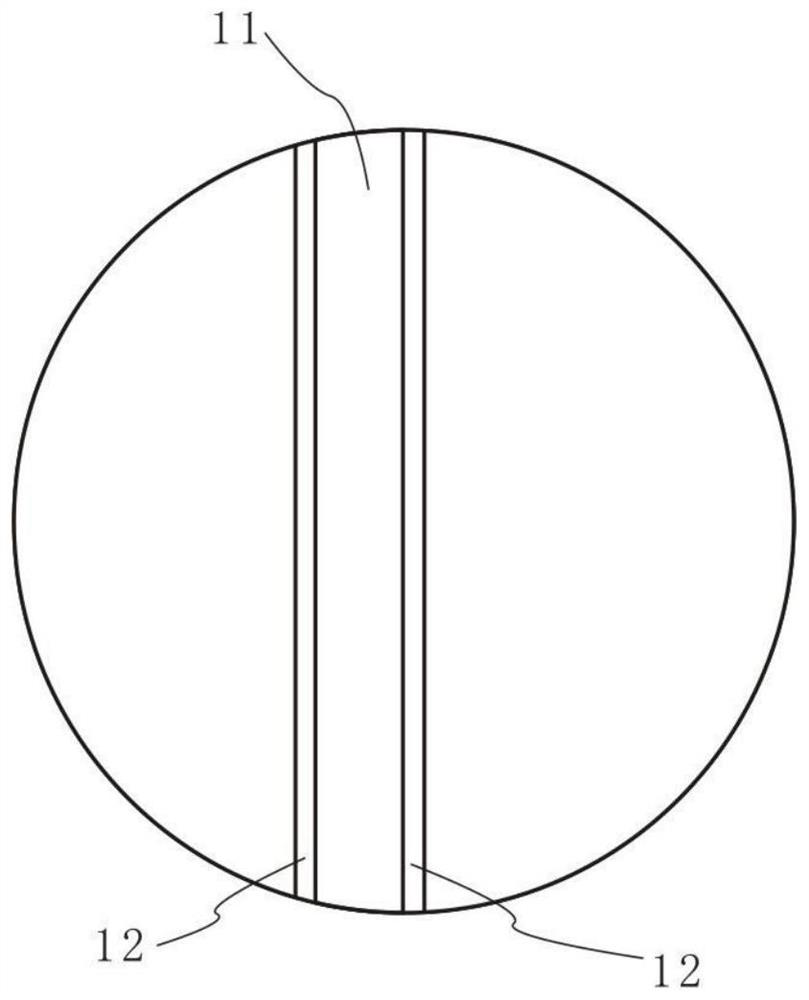

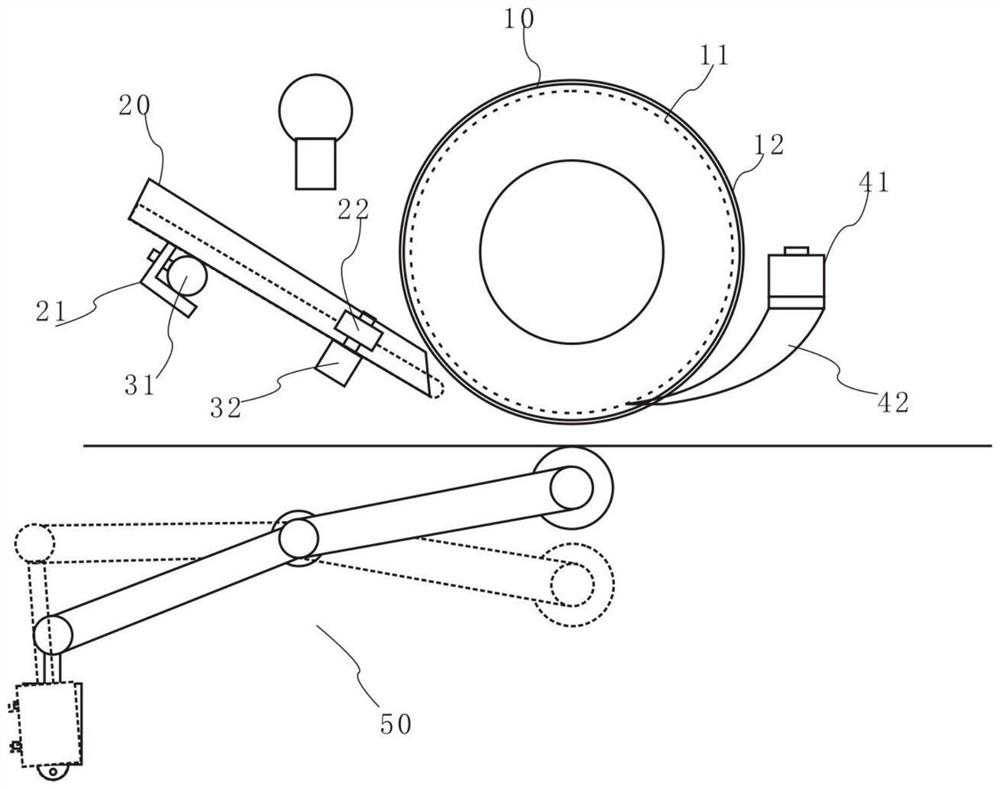

[0027] The present invention will be further described below in conjunction with the accompanying drawings:

[0028] The present embodiment provides a processing technique of thick-stuffed seaweed, comprising the following steps:

[0029] Step 1) single-sheet delivery: make two rows of single-layer seaweed sheets intermittently transported to the roller coating station, the single-layer seaweed sheet is the dried seaweed sheet, and the surface area of the generally selected seaweed sheet is 19cm× 21cm, the moisture content is less than 1%. When delivering vegetables, the following method can be used: first stack multiple nori sheets on the single sheet feeding device, the single sheet feeding device has two supply positions, and each stack of nori sheets is placed on the feeding device of the single sheet feeding device respectively. On the position, two rows of single-layer seaweed sheets are respectively sent out by the single-sheet feeding device, and then intermittently...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com