Device and method for extraction and/or purification

A purification device and extraction technology, applied in the field of analytical chemistry, can solve the problems of slow speed and inconvenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The device in Example 1 is provided with four cylindrical containers 1 arranged side by side, and an oscillator 4 is provided. The device in Example 2 is provided with four cylindrical containers 1 arranged side by side, but no oscillator 4 is provided. In the device of Example 3, the cylindrical container 1 is set on a 96-well plate, and the oscillator 4 is not provided.

[0087] Example 1

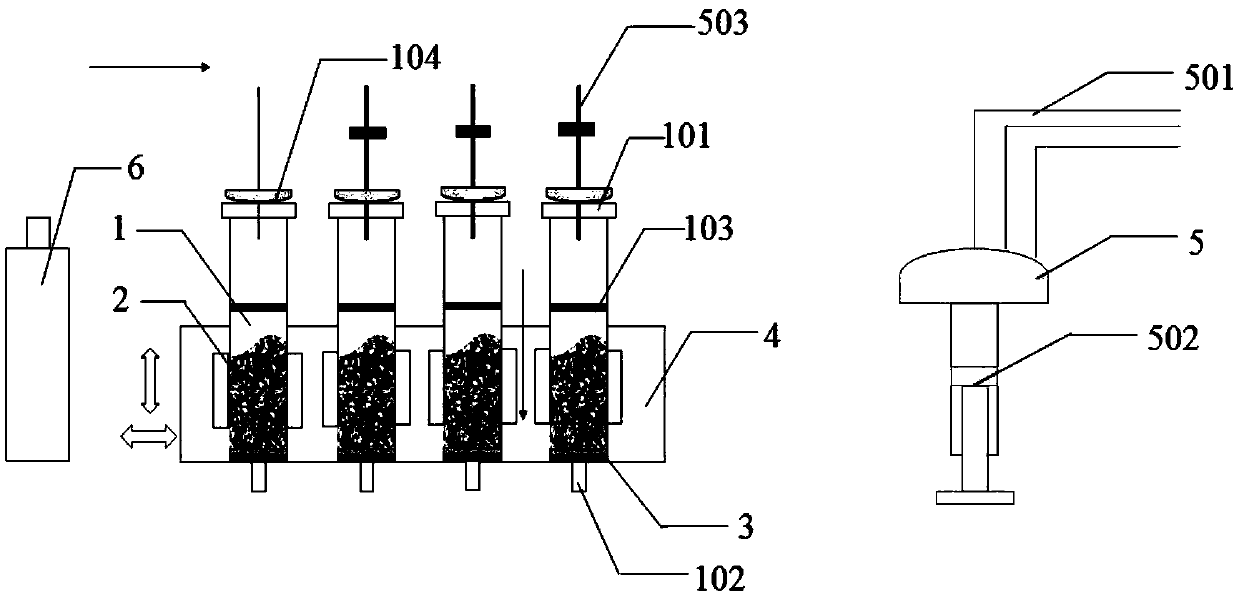

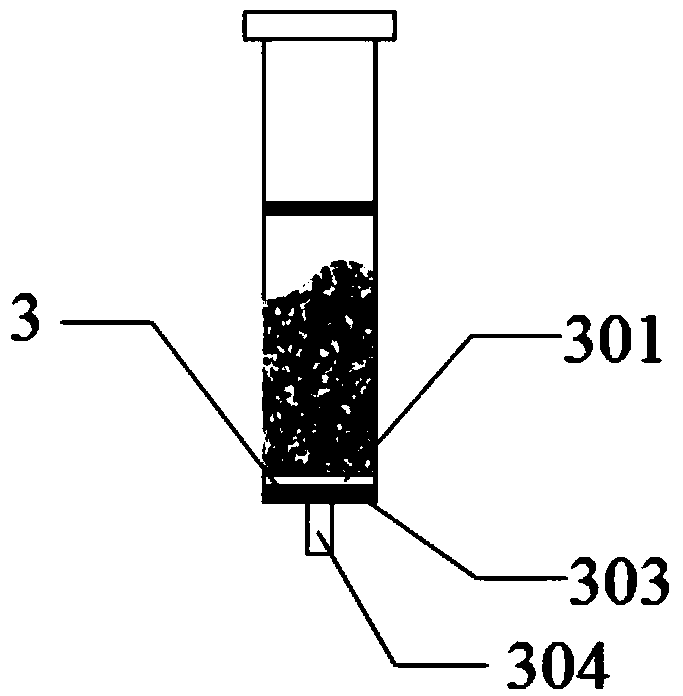

[0088] The structure of the device with oscillator 4 is as figure 1 As shown, the device includes a liquid addition system 5 , a pressurization system, a cylindrical container 1 , an extraction material 2 , a stirring device and a bottom packaging device 3 . The pressurization system is connected to the top inlet 101 of the cylindrical container 1 through a pipeline to provide discharge pressure for the materials in the cylindrical container 1 . The extraction material 2 is used as the adsorption phase, loosely packed inside the cylindrical container 1, and can be displaced in t...

Embodiment 2

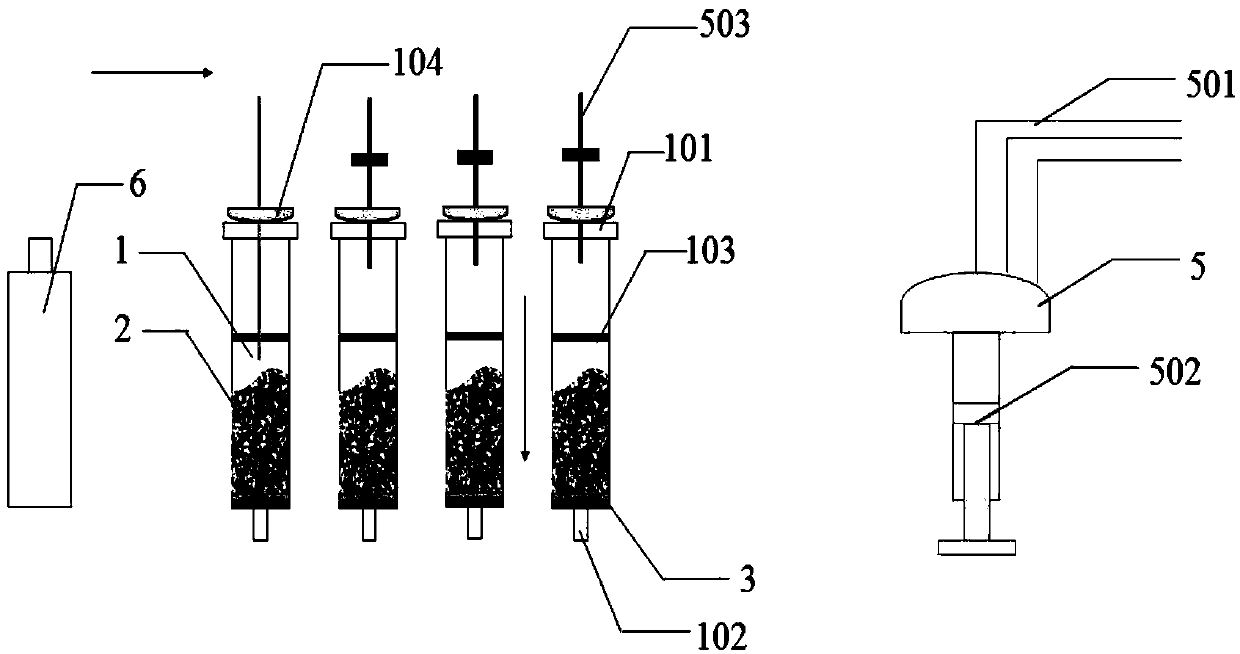

[0095] The structure of the device without oscillator 4 is as image 3 As shown, the device includes a liquid addition system 5 , a pressurization system (serving as a stirring device at the same time), a cylindrical container 1 , an extraction material 2 and a bottom packaging device 3 . The pressurized system is connected to the top inlet 101 of the columnar container 1 through a pipeline to provide discharge pressure for the material in the columnar container 1; the extraction material 2 is used as an adsorption phase, loosely packed inside the columnar container 1, and can be placed in the columnar container 1 Displacement occurs in the column; the cylindrical container 1 is the main part of extraction and purification, and the sample solution and extraction material 2 are adsorbed in the cylindrical container 1. The bottom packaging device 3 is arranged at the bottom of the cylindrical container 1. When the cylindrical container 1 is under normal pressure, the bottom pack...

Embodiment 3

[0100] The overall structure of the device of the present embodiment and the supporting structure of the cylindrical container 1 are as follows Figure 5 , 6As shown, the device includes a liquid addition system 5 , a pressurization system (serving as a stirring device at the same time), a cylindrical container 1 , an extraction material 2 and a bottom packaging device 3 . The pressurized system is connected to the top inlet 101 of the columnar container 1 through a pipeline to provide discharge pressure for the material in the columnar container 1; the extraction material 2 is used as an adsorption phase, loosely packed inside the columnar container 1, and can be placed in the columnar container 1 Displacement occurs in the column; the cylindrical container 1 is the main part of extraction and purification, and the sample solution and extraction material 2 are adsorbed in the cylindrical container 1. The bottom packaging device 3 is arranged at the bottom of the cylindrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com