Multilevel pressurized gas stirring tank

A technology of pressurized gas and stirring tank, which is applied in the field of air stirring tank and multi-stage pressurized gas stirring tank, which can solve the problems of uneven stirring, stirring failure, and magnetic stirring strength is not as strong as mechanical stirring, so as to reduce mechanical stirring movement Components, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

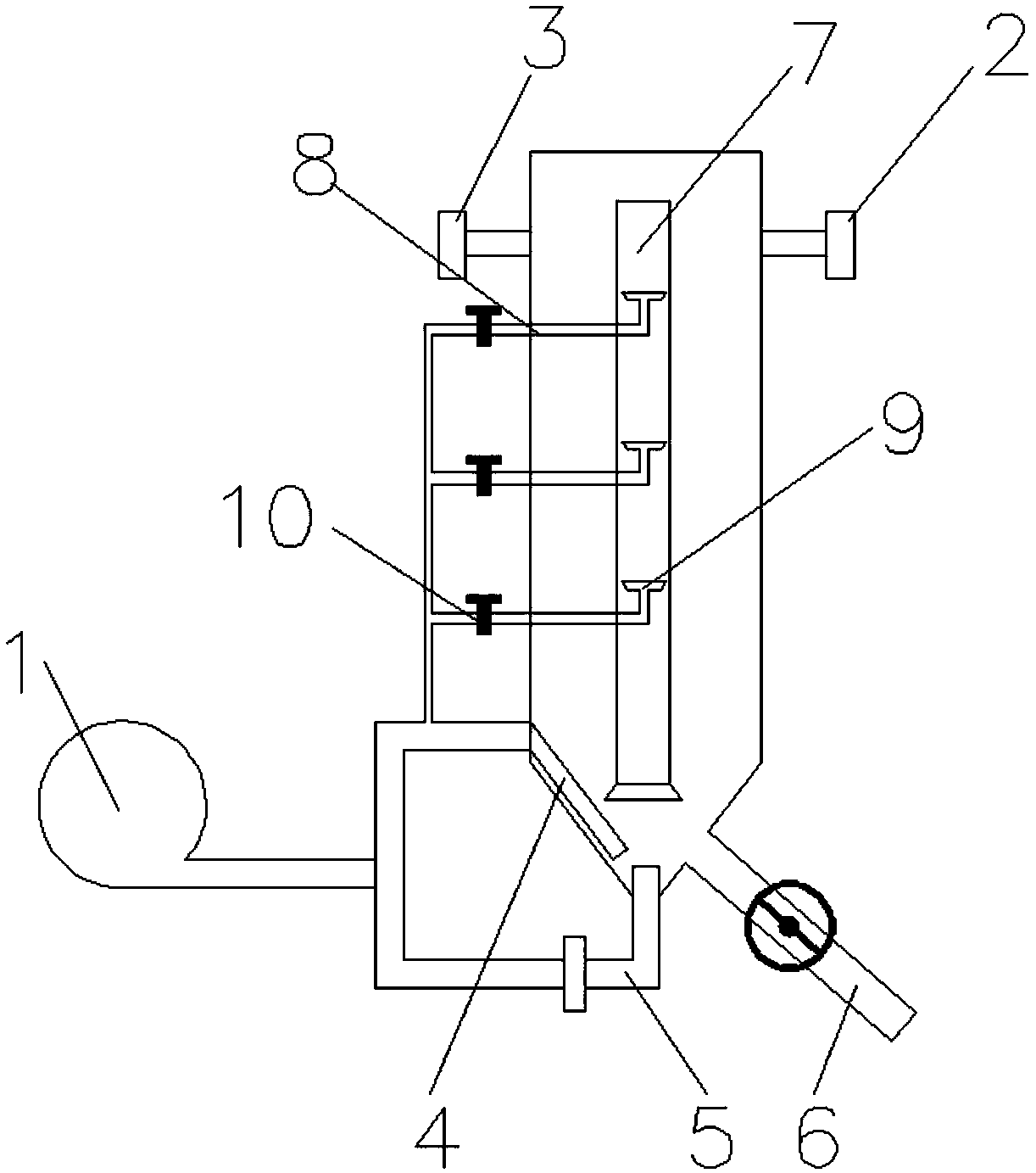

[0029] like figure 1 and 2 As shown, a kind of multi-stage pressurized gas mixing tank provided by the present embodiment includes: an air compressor 1, an upper ore pulp outlet 2, an ore pulp inlet 3, an air-assisted pipe 4 and an air explosion pipe respectively connected to the air compressor 1 5. It is characterized in that it also includes a central tube 7 arranged inside the gas stirring tank, and the pressure at the lower end of the central tube 7 is gradually increased by using multi-stage compressed air, and the ore slurry is gradually lifted to the upper part in the central tube 7 via the central tube 7 The outlet overflows, and then descends outside the central tube 7 to form a circular flow, and become a uniform slurry after several times of stirring.

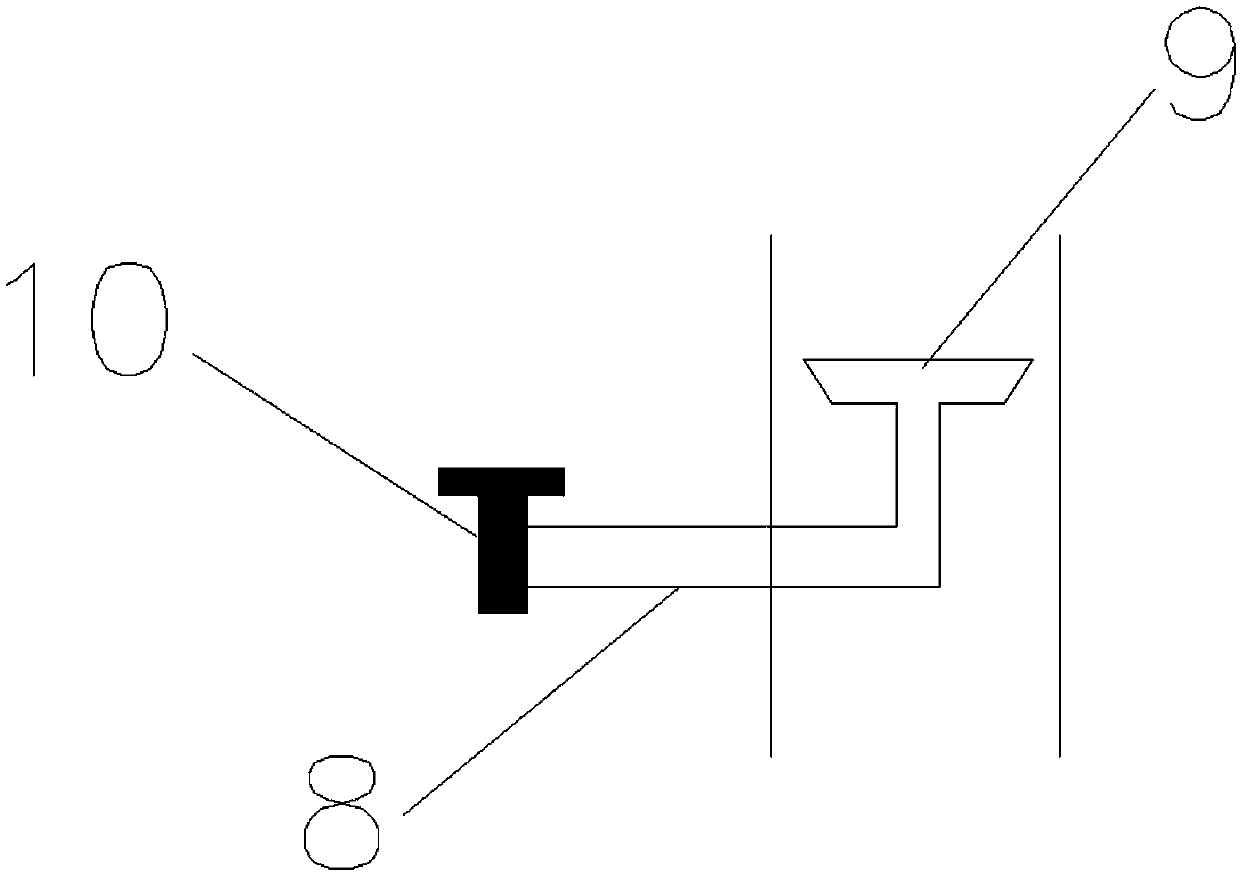

[0030] In this embodiment, as figure 1 and figure 2 As shown, the stepwise increase of the pressure at the lower end of the central tube 7 by using multistage compressed air is realized by the following equipment...

Embodiment 2

[0033] In this embodiment, as figure 1 and figure 2As shown in the figure, similar to the first embodiment, the different technical solution is: enter the material to be stirred from the pulp inlet 3, and use the compressed air introduced from the bottom of the central pipe 7 by the air compressor 1 to drive the pulp in the central pipe 7 to rise to the central pipe. 7. The upper port overflows, and then descends outside the central pipe 7 to form a circulating flow. After many times of stirring, the slurry that is uniform or reaches the standard is transferred from the slurry outlet 2; the bottom of the stirring tank is conical and is provided with a sludge discharge pipe 6, Open the valve provided on the sludge discharge pipe 6 to remove the sludge accumulation at the bottom of the multi-stage pressurized gas stirring tank.

Embodiment 3

[0035] In this embodiment, as figure 1 and figure 2 As shown, similar to the first embodiment, the different technical solutions are: in this embodiment, as figure 1 and figure 2 As shown, the pressure regulating valve 10 adjusts the pressure at the end of the pressure pipe 8 at the position so that it becomes a certain constant pressure value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com