Bamboo vertical and horizontal flattening process

A process method and bamboo technology, applied in the direction of sugarcane mechanical processing, mechanical equipment, etc., can solve the problems of reducing the risk of production efficiency, deep cracks in bamboo boards, and high risk, so as to improve physical and mechanical properties, reduce slicing thickness, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

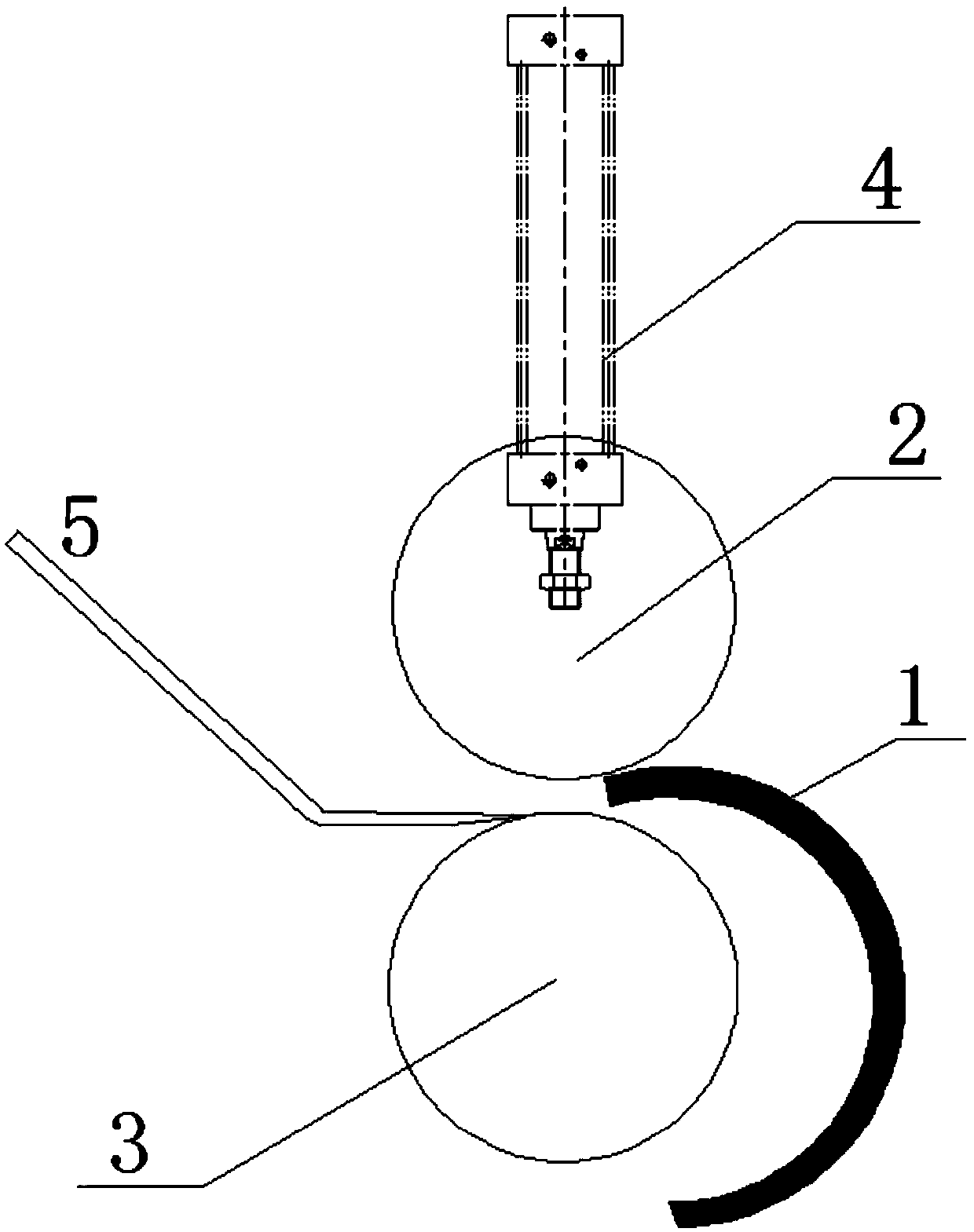

Image

Examples

specific Embodiment 1

[0024] A technical method for vertically and horizontally flattening bamboo, comprising the following steps:

[0025] Step 1, first cut the bamboo tube to the required length, then remove the inner section, then remove the outer section, and combine with the greening treatment. Wherein the deblueing treatment is realized by installing a stop ring on the deblueing milling cutter shaft and applying an air pressure of 0.3-0.7 MPa, preferably 0.3 MPa, and the de-blueing thickness is 0.4-0.6 mm, preferably 0.4 mm.

[0026] Step 2: Carry out longitudinal slits on the bamboo tube processed in step 1. The longitudinal slits are sawed with a circular saw blade to perform longitudinal slits on the bamboo tubes. The width of the longitudinal slits is 1-3 mm, preferably 1 mm; then perform high-temperature softening treatment The high-temperature softening treatment is carried out in a closed pressurized tank, the heating and softening medium is saturated steam, the temperature is 160-180°...

specific Embodiment 2

[0030] A technical method for vertically and horizontally flattening bamboo, comprising the following steps:

[0031] Step 1, first cut the bamboo tube to the required length, then remove the inner section, then remove the outer section, and combine with the greening treatment. Wherein the deblueing treatment is realized by installing a limit ring on the deblueing milling cutter shaft and applying an air pressure of 0.3-0.7 MPa, preferably 0.5 MPa, and the deblueing thickness is 0.4-0.6 mm, preferably 0.5 mm.

[0032] Step 2: Carry out longitudinal slits on the bamboo tube processed in step 1. The longitudinal slits are sawed with a circular saw blade to carry out longitudinal slits on the bamboo tubes. The width of the longitudinal slits is 1-3 mm, preferably 2 mm; then perform high-temperature softening treatment The high-temperature softening treatment is carried out in a closed pressurized tank, the heating and softening medium is saturated steam, the temperature is 160-18...

specific Embodiment 3

[0036] A technical method for vertically and horizontally flattening bamboo, comprising the following steps:

[0037] Step 1, first cut the bamboo tube to the required length, then remove the inner section, then remove the outer section, and combine with the greening treatment. Wherein the deblueing treatment is realized by installing a stop ring on the deblueing milling cutter shaft and applying an air pressure of 0.3-0.7 MPa, preferably 0.7 MPa, and the de-blueing thickness is 0.4-0.6 mm, preferably 0.6 mm.

[0038] Step 2: Carry out longitudinal slits on the bamboo tube processed in step 1. The longitudinal slits are sawed with a circular saw blade to perform longitudinal slits on the bamboo tubes. The width of the longitudinal slits is 1-3 mm, preferably 1 mm; then perform high-temperature softening treatment The high-temperature softening treatment is carried out in a closed pressurized tank, the heating and softening medium is saturated steam, the temperature is 160-180°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com