High-strength lightweight multi-layered carbon fiber special-shaped bulkhead plate

A carbon fiber and bulkhead panel technology, which is applied in the field of high-strength, light-weight and multi-layer carbon fiber special-shaped bulkhead panels, can solve the problems of increasing the load ratio of the bulkhead panel, the mass of the panel is large, and the load ratio is low, and achieves light weight. , low density, the effect of increasing toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

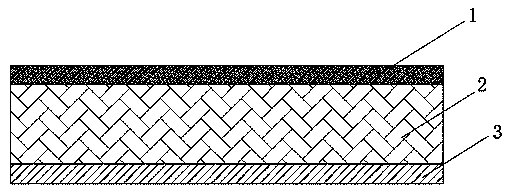

[0019] See attached figure 1 , a high-strength and lightweight multi-layer carbon fiber special-shaped bulkhead panel. The carbon fiber special-shaped bulkhead panel includes an outer panel 1, a structural foam sandwich 2, and an inner panel 3 from the outside to the inside. The structural foam sandwich 2 is used to strengthen the cabin wall. The impact resistance of the panel increases the load ratio of the cabin, and also reduces the overall quality of the panel. The outer panel 1, the structural foam sandwich 2, and the inner panel 3 are bonded with each other by embedding resin through a vacuum introduction process, and the vacuum introduction process can make the airtightness between the outer panel 1, the structural foam sandwich 2, and the inner panel 3 Better, the cabin looks more beautiful. The outer panel 1 is formed by gluing and pressing four layers of carbon fiber cloth, and the inner panel 3 is formed by gluing and pressing three layers of carbon fiber cloth. Th...

Embodiment 2

[0023] The difference between this embodiment and Embodiment 1 is that the outer panel 1, the structural foam sandwich 2, and the inner panel 3 are bonded to each other by gluing, and the first layer of the outer panel 1 is made of carbon fiber plain cloth. , the laying angle of the second layer of carbon fiber cloth of the outer covering plate 1 is -45°, the laying angle of the third layer of carbon fiber cloth of the outer covering plate 1 is 90°, and the laying angle of the fourth layer of carbon fiber cloth of the outer covering plate 1 is 45°, The laying angle of the first layer of carbon fiber cloth of the inner cover plate 3 is -45°, the laying angle of the second layer of carbon fiber cloth of the inner cover plate 3 is 0°, and the laying angle of the third layer of carbon fiber cloth of the inner cover plate 3 is 45°. The grade of carbon fiber cloth is M40.

[0024] Other structures are consistent with Example 1.

Embodiment 3

[0026] The difference between this embodiment and Embodiment 1 is that the angle between the two adjacent layers of carbon fiber fabrics of the outer panel 1 and the inner panel 3 is 60°C after laying, and the carbon fiber fabrics of the outer panel 1 and the inner panel 3 The specific laying angle is:

[0027] The first layer of the outer panel 1 is made of carbon fiber plain cloth, the laying angle of the second layer of carbon fiber cloth of the outer panel 1 is 60°, and the laying angle of the third layer of carbon fiber cloth of the outer panel 1 is 0°. The laying angle of the fourth layer of carbon fiber cloth of mask 1 is -60°, and the density is 300g / m 2 , the laying angle of the first layer of carbon fiber cloth of the inner cover plate 3 is -60°, the laying angle of the second layer of carbon fiber cloth of the inner cover plate 3 is 0°, and the density is 400g / m 2 , the laying angle of the third layer of carbon fiber cloth of the inner panel 3 is 60°, and the densi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com