Surface treater for electronic yarn drawing equipment

An electronic yarn and processor technology, applied in the field of electronic yarn drawing equipment, can solve problems such as unstable coating effect of sizing agent, failure to meet the production process, and influence on the oiling effect of tow, so as to improve the wind-shielding effect and reduce the distance , good coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

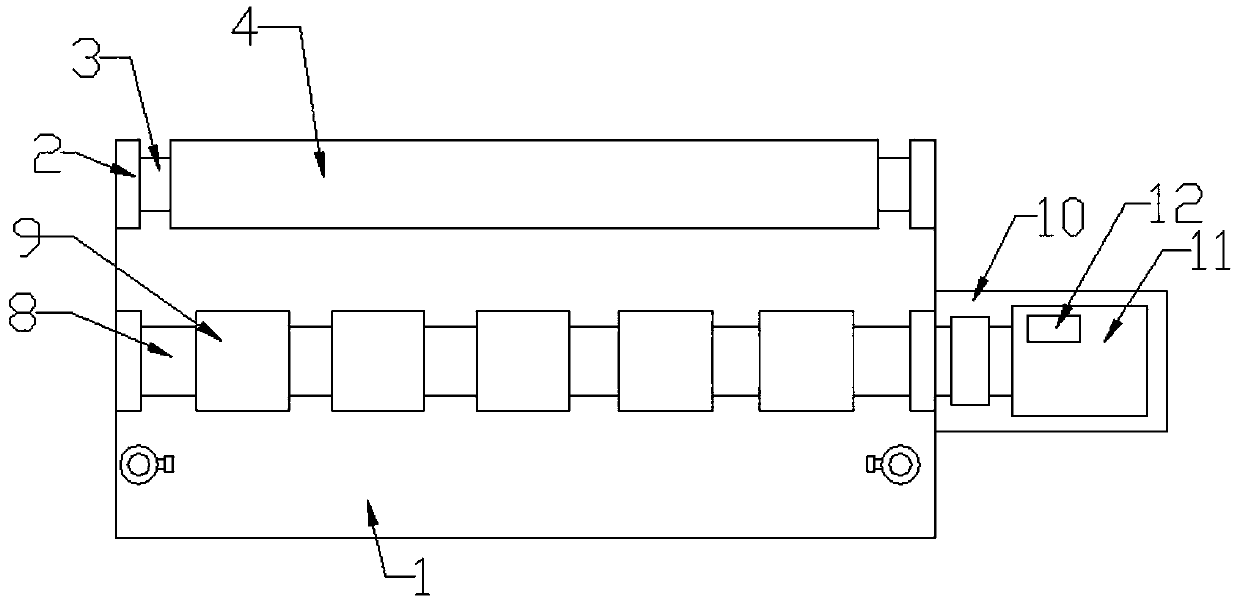

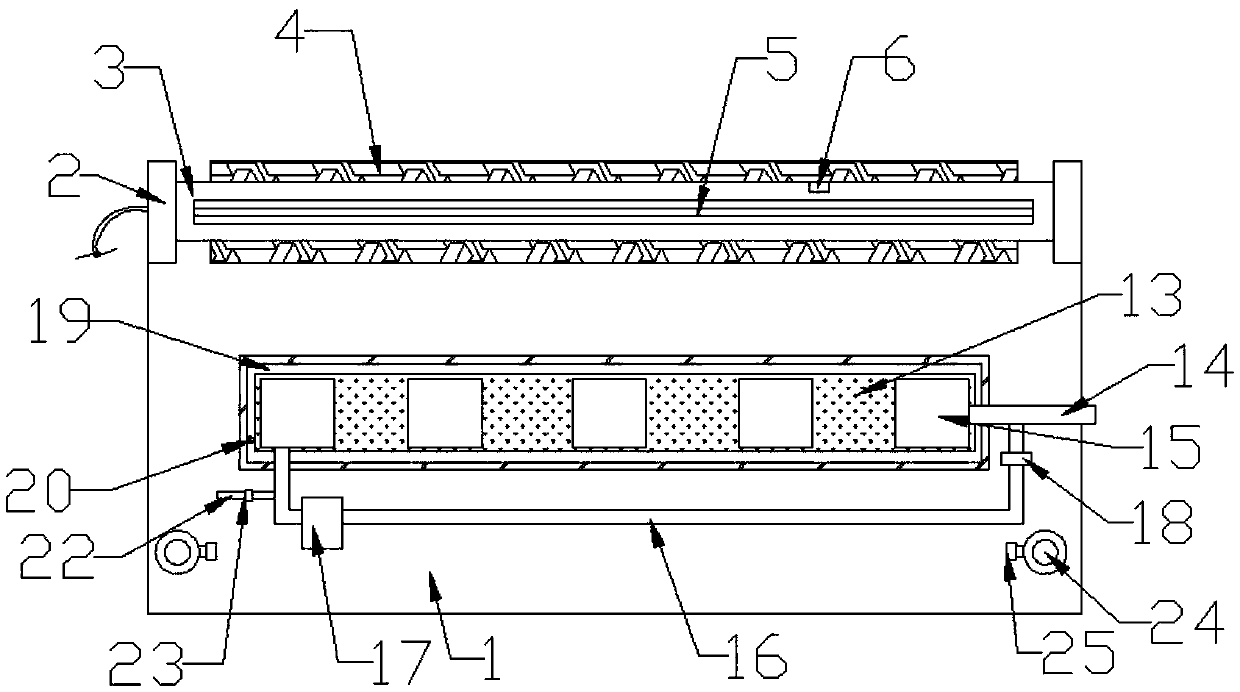

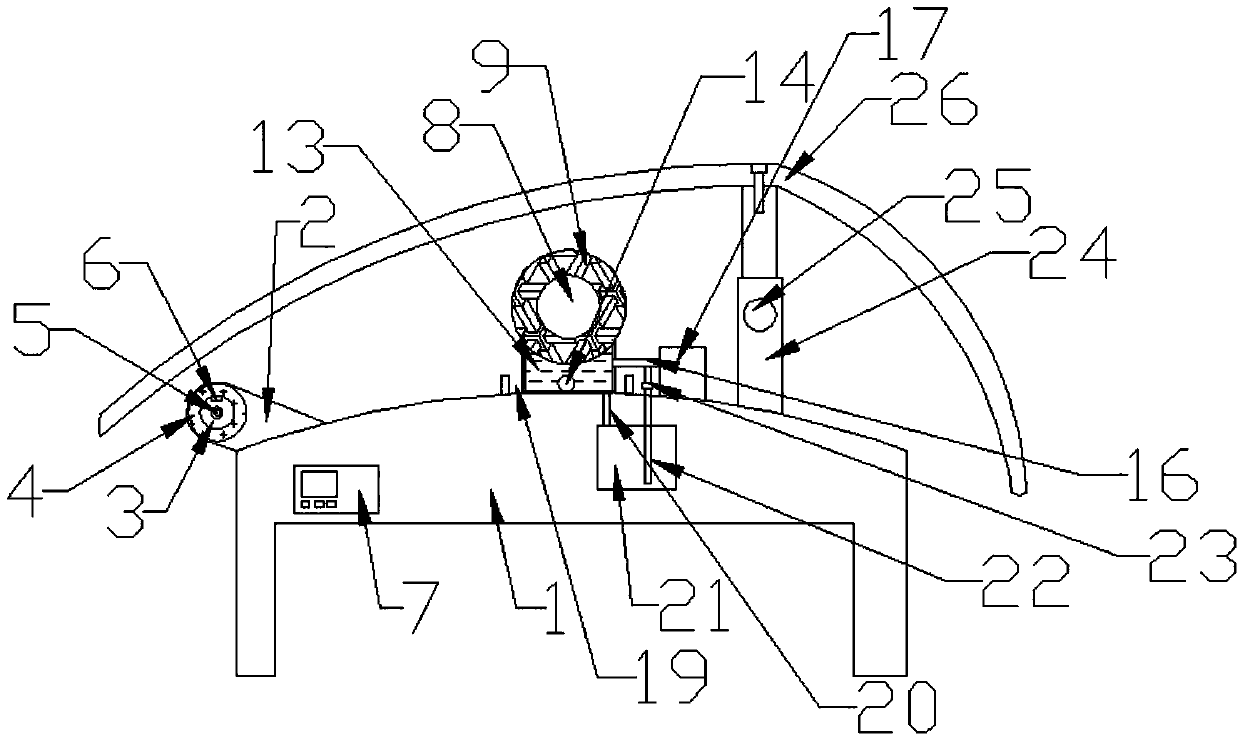

[0024] Such as Figure 1-3 As shown, a surface processor of an electronic yarn drawing equipment includes a workbench 1, a mounting seat 2, a rotating roller 8, a rubber sleeve 9, a servo motor 11, an oil box 13, and an arc-shaped oil cover 26. A receiving roller 3 is installed on the edge through the mounting seat 2. The receiving roller 3 is covered with a sponge-made suction jacket 4, and the receiving roller 3 is also installed with a low-temperature heating tube 5, and the middle of the workbench 1 is also installed The base 2 is equipped with a rotating roller 8, and a number of rubber sleeves 9 are sleeved on the rotating roller 8. One end of the rotating roller 8 is also connected to the output end of the servo motor 11 through a coupling, and the oil box 13 is installed on the rotating Below the roller 8, there are several oil ports 15 on the oil box 13, and the bottom end of each rubber sleeve 9 is close to an oil port 15, so that the rotating rubber sleeve 9 is impre...

Embodiment 2

[0029] Such as Figure 1-3 As shown, an oil inlet pipe 14 is connected below one end of the oil box 13, and the other end of the oil box 13 is connected to the oil inlet pipe 14 through an oil return pipe 16. An oil return pump 17 is installed on the oil return pipe 16. The oil tank 19 is divided into an oil tank 19, and the oil tank 19 is connected to an oil tank 21 through an oil accumulation pipe 20. The oil accumulation tank 21 is installed in the workbench 1, and the oil accumulation tank 21 is also connected to the oil return pipe 16 through a pipe 22.

[0030] The surplus wetting agent can enter the oil accumulation tank 21 through the oil tank 19, and be introduced into the oil inlet pipe 14 again through the oil return pump 17 and the oil return pipe 16, and return to the oil box 13 through the oil inlet pipe 14 for repeated use.

[0031] A first valve 18 is installed at the end of the oil return pipe 16 to control the on and off of the oil return pipe 16, and a second val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com