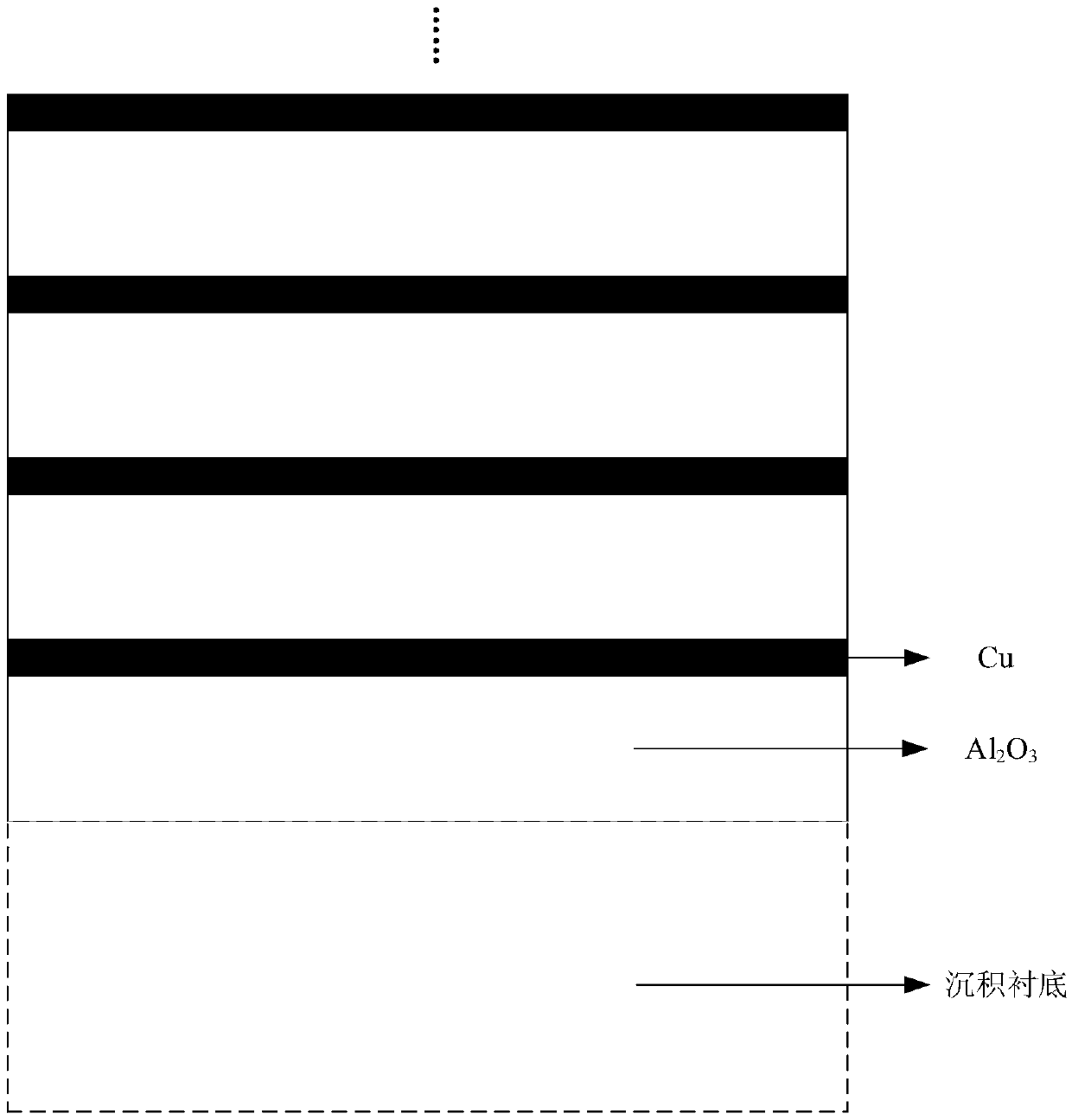

Microchannel plate and method for preparing high-resistance thin film with Cu being doped with Al2O3 on inner wall of microchannel plate

A technology of microchannel plate and microchannel, which is applied in the field of thin film doping, can solve the problems of resistivity change and unstable performance of microchannel plate, and achieve the effect of compact structure, excellent thermal stability and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

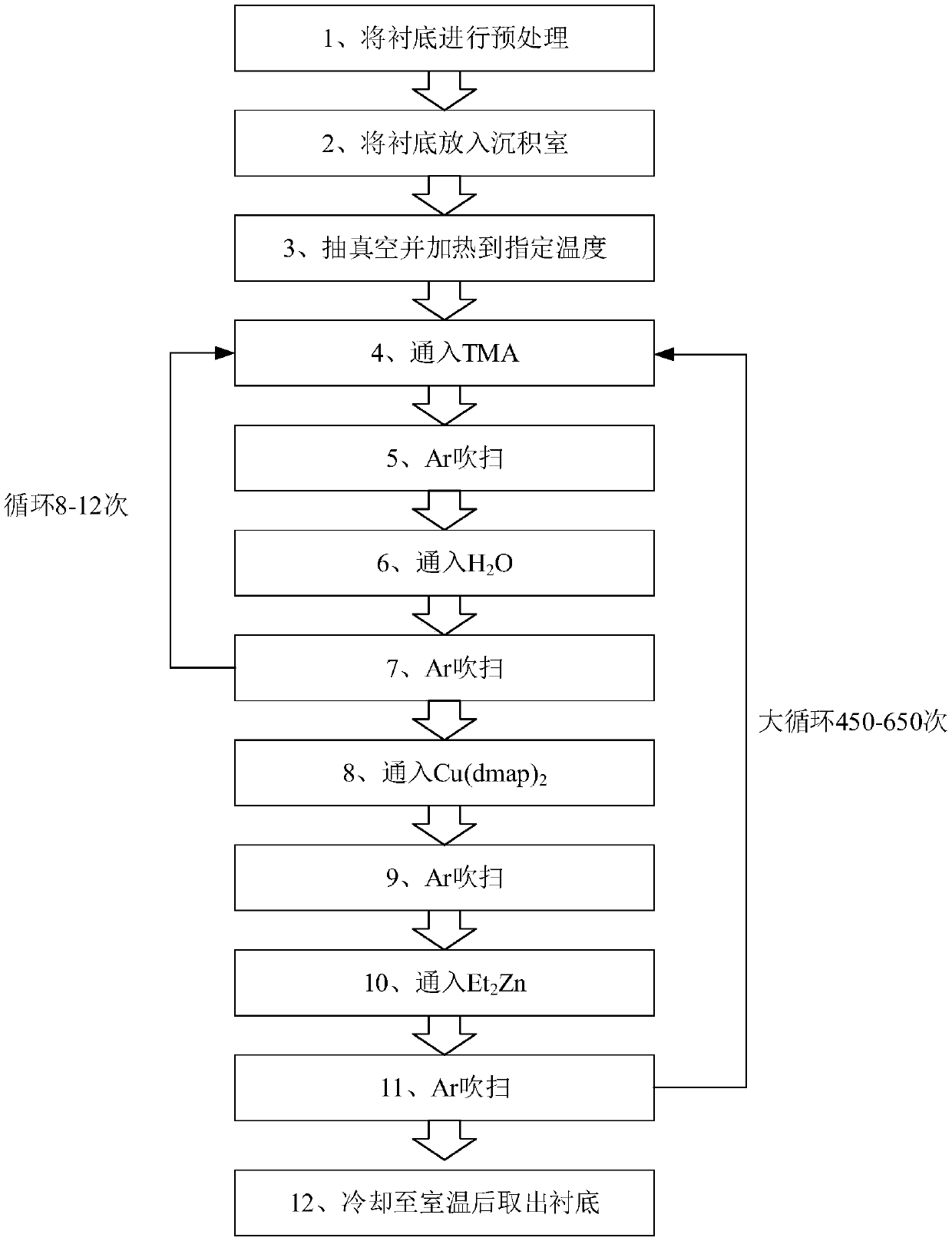

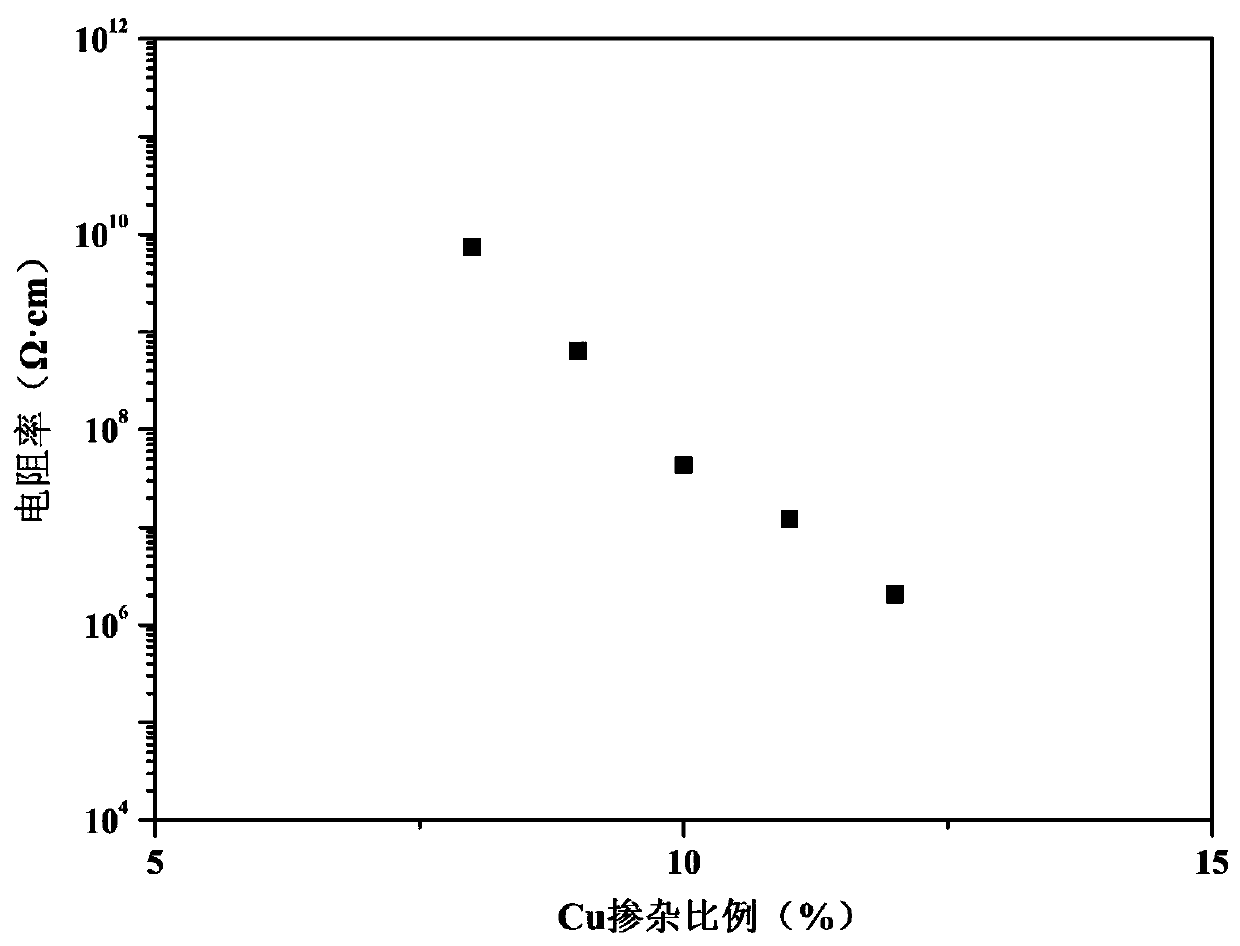

[0046] Place the microchannel plate in RCA standard cleaning solution SC-2 (HCl: H 2 o 2 :H 2 O=1:1:5), after ultrasonic cleaning at 85°C for 10 minutes, placed in HF solution (HF:H 2 (0=1:50) after ultrasonic cleaning, put the microchannel plate into the atomic layer deposition chamber, and vacuumize to 10 -1 Pa, and the temperature of the deposition chamber and the microchannel plate was heated to 100 °C, and the Al 2 o 3 deposition, i.e. TMA / Ar / H 2 O / Ar=(0.03s / 10s / 0.03s / 10s), after 12 cycles, 1 Cu deposition, ie Cu(dmap) 2 / Ar / Et 2 Zn / Ar=(2s / 10s / 0.5s / 10s), 12 times Al 2 o 3 After the deposition cycle and 1 Cu deposition is a large cycle, the deposition is stopped after 450 large cycles, and after the deposition chamber is lowered to room temperature, the deposition chamber is opened, and the deposited Cu-doped Al 2 o 3 Thin film microchannel plate.

Embodiment 2

[0048] Place the microchannel plate in RCA standard cleaning solution SC-2 (HCl: H 2 o 2 :H 2 O=1:1:5), after ultrasonic cleaning at 85°C for 10 minutes, placed in HF solution (HF:H 2 (0=1:50) after ultrasonic cleaning, put the microchannel plate into the atomic layer deposition chamber, and vacuumize to 10 -2 Pa, and the temperature of the deposition chamber and the microchannel plate was heated to 105 °C, and the Al 2 o 3 deposition, i.e. TMA / Ar / H 2 O / Ar=(0.03s / 10s / 0.03s / 10s), after 11 cycles, 1 Cu deposition, ie Cu(dmap) 2 / Ar / Et 2 Zn / Ar=(2s / 10s / 0.5s / 10s), 11 times Al 2 o 3 After the deposition cycle and 1 Cu deposition is a large cycle, the deposition is stopped after 500 large cycles, and after the deposition chamber is lowered to room temperature, the deposition chamber is opened, and the deposited Cu-doped Al 2 o 3 Thin film microchannel plate.

Embodiment 3

[0050] Place the microchannel plate in RCA standard cleaning solution SC-2 (HCl: H 2 o 2 :H 2 O=1:1:5), after ultrasonic cleaning at 85°C for 10 minutes, placed in HF solution (HF:H 2 (0=1:50) after ultrasonic cleaning, put the microchannel plate into the atomic layer deposition chamber, and vacuumize to 10 -3 Pa, and the temperature of the deposition chamber and the microchannel plate was heated to 110°C, and the Al 2 o 3 deposition, i.e. TMA / Ar / H 2 O / Ar=(0.03s / 10s / 0.03s / 10s), after 10 cycles, 1 Cu deposition, ie Cu(dmap) 2 / Ar / Et 2 Zn / Ar=(2s / 10s / 0.5s / 10s), 10 times Al 2 o 3 After the deposition cycle and one Cu deposition is a large cycle, the deposition is stopped after 550 large cycles, and after the deposition chamber is lowered to room temperature, the deposition chamber is opened, and the deposited Cu-doped Al 2 o 3 Thin film microchannel plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com