A multi-phase and multi-fluid injection system controlled by a single pump

An injection system and multi-fluid technology, applied in the field of multi-phase and multi-fluid injection systems, can solve problems such as expensive system cost, cumbersome experimental design, and complicated instrument operation, and achieve simple experimental design, reduced experimental cost, and easy cleaning and drying Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

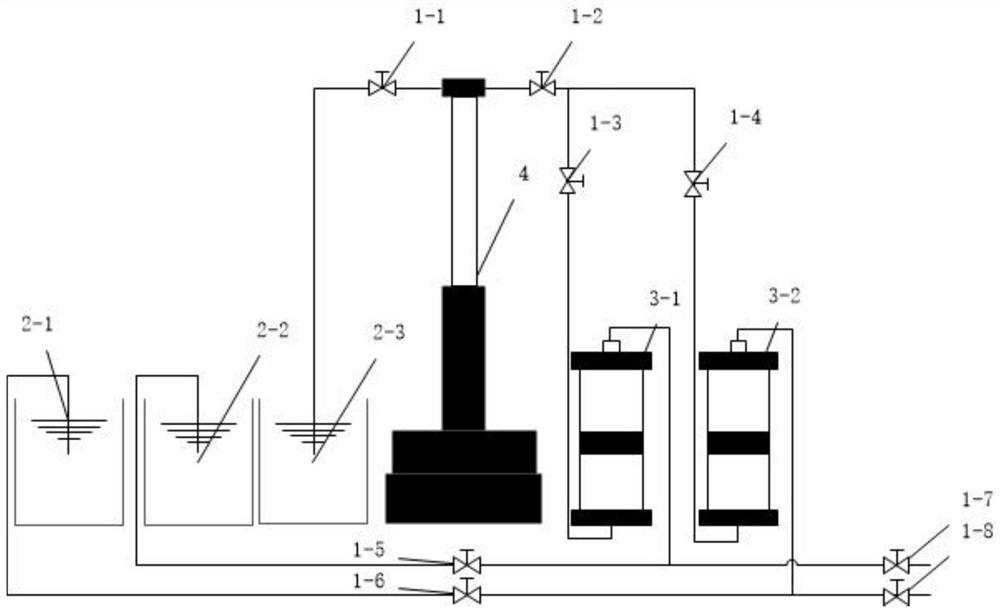

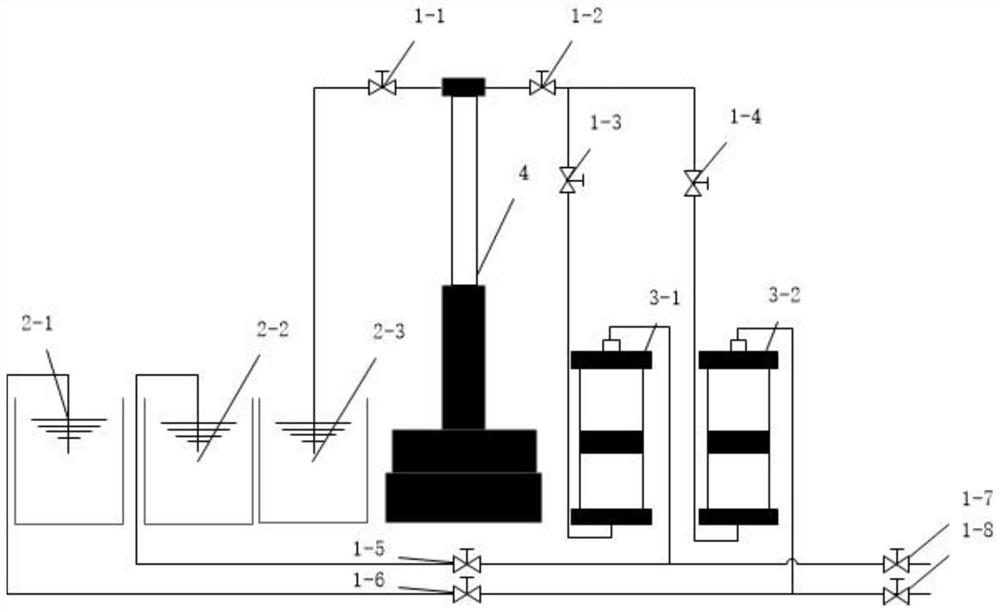

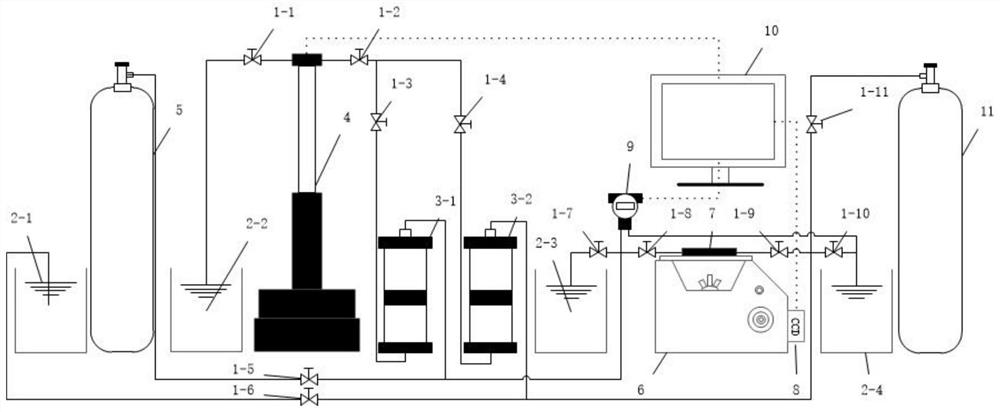

[0016] image 3 is CO at room temperature and pressure 2 The diagram of the microscopic visualization experiment system for displacing brine is used as an example to describe the specific implementation of the present invention in detail. Because the experiment is a displacement experiment, two intermediate piston containers are selected, and an anti-corrosion intermediate piston container 3-1 is used to hold CO 2 , another common intermediate piston container 3-2 holds other fluids. Before the start of the experiment, close all the valves, place the piston in the middle piston container to the bottom, fill the 2-2 container with enough water, open the valve 1-1, operate the ISCO plunger pump, implement the run operation, and release the air in the pump Exhaust, at the end implement the refill operation to suck e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com