Polyethylene compositions, and articles made therefrom

A composition, polyethylene technology, applied in the direction of coating, etc., can solve the problem of not being able to transport gravel water-based slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0097] The following compositions are used in the examples described below.

example 1

[0099] Ultra-high molecular weight polyethylene has a weight average molecular weight of 8,000,000g / mol, a density of 0.925g / cc, an intrinsic viscosity of 28dL / g, and an average particle size D50 of 150μm (UTEC TM 6541, available from Braskem (Brazil), and thermoplastic polyolefin elastomer (INFUSE TM 9010, density=0.877g / cc, melt index I2=0.5g / 10min, Mw / Mn of 2.6, available from The Dow Chemical Company in the United States) and blended at a weight ratio of 65:35 to form a composition. Then use a LabTech 26mm twin-screw compounder to combine the composition with 600ppm of fluoropolymer processing aid (melt flow index (265°C, 5kg) 10g / 10 minutes under the following processing parameters (Dynamar FX5911, available from United States 3M company (3M, Inc., USA))) mixing to produce uniform pellets:

[0100] Barrel temperature: 275℃ flat temperature curve

[0101] Mold temperature: 280℃ flat temperature curve

[0102] Screw RPM: 130; Torque: 80%; Melting temperature: 280°C.

[0103] Th...

example 2

[0105] Ultra-high molecular weight polyethylene has a weight average molecular weight of 8,000,000g / mol, a density of 0.925g / cc, an intrinsic viscosity of 28dL / g, and an average particle size D50 of 150μm (UTEC TM 6541, available from Brasco), and thermoplastic polyolefin elastomer (INFUSE TM 9010, density=0.877g / cc, melt index I2=0.5g / 10min, Mw / Mn is 2.6, it can be purchased from Dow Chemical Company in the United States and blended at a weight ratio of 55:45 to form a composition. Using a LabTech 26mm twin-screw compounder under the following processing parameters, the composition and 600ppm fluoropolymer processing aid (melt flow index (265°C, 5kg) of 10 g / 10 minutes (Dynamar FX5911, available from the United States) 3M company)) mixed to produce uniform pellets:

[0106] Barrel temperature: 275℃ flat temperature curve

[0107] Mold temperature: 280℃ flat temperature curve

[0108] Screw RPM: 130; Torque: 80%; Melting temperature: 280°C.

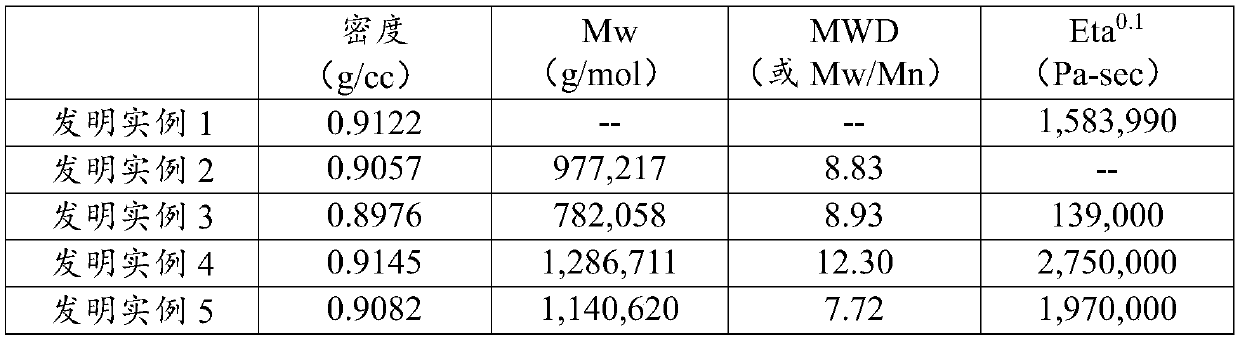

[0109] The characteristics of the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com