Melting and chemically modified light tank chain track backing rubber composite material and preparation method thereof

A technology of composite materials and tank chains, applied in the field of rubber-plastic composite modified materials, can solve problems such as poor performance indicators, and achieve the effects of good cold resistance, good tear resistance, and outstanding anti-reversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

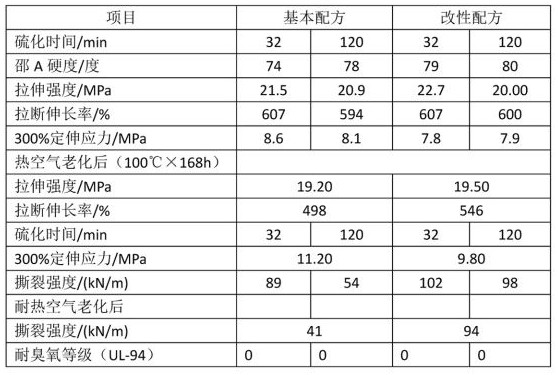

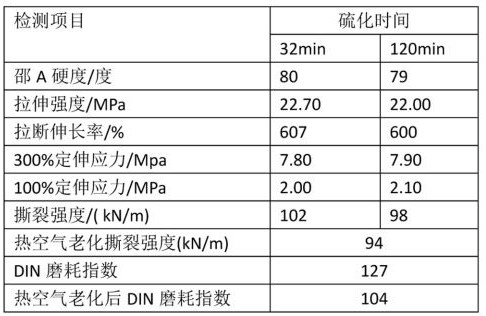

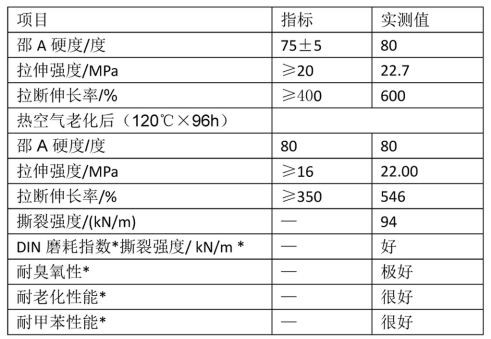

Embodiment 1

[0044]Components: natural rubber NR-20#: 80 parts; styrene-butadiene rubber SBR-1502: 20 parts; high styrene resin HS-860: 20 parts; PL-90: 0.6 parts; carbon black N134: 53 parts; high dispersion White carbon black: 5 parts; graphene: 1 part; cold-resistant oil DOA: 6 parts; zinc oxide ZnO: 3 parts; stearic acid SA: 2 parts; antioxidant 4020: 2 parts; antioxidant 4010NA: 2 parts; rubber Protective wax: 3.5 parts; terpene phenolic resin: 3 parts; polyethylene glycol PEG-4000: 2 parts; accelerator CZ: 0.95 parts; vulcanizing agent S: 1.15 parts; DCPD resin: 1.5 parts; modifier HVA- 2: 1.0 copies;

[0045] Process steps:

[0046] (1) Preparation:

[0047] ①Raise the temperature of the heating type high and low two-speed mixer to 60°C, and set it aside;

[0048] ②Raise the temperature of the heating type open mill to 65°C and set it aside;

[0049] ③Heat the heating type internal mixer and the pressurized open mixing machine to 120°C for use;

[0050] ④ Accurately weigh the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com