Hydrodechlorination method of alkylated oil

A technology for hydrodechlorination and alkylation of oil, which is applied in hydrotreating process, treatment of hydrocarbon oil, petroleum industry, etc., can solve problems such as unqualified products and substandard product quality, achieve low maintenance cost, improve dehydration, etc. Chlorine efficiency, easy to achieve results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

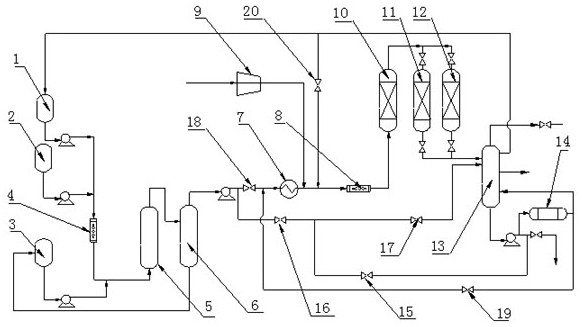

Embodiment 1

[0050] According to the scheme of the present invention, a new alkylation unit is built. After the alkylation reaction is completed, the ionic liquid is separated by the settling tank 6, and then the feed pump, the heat exchanger 7 and the hydrogen are fully mixed and dissolved in the SX type static mixer, and then enter the hydrodechlorination reactor 10. The reaction conditions For: reaction pressure 1.5MPa﹑liquid hour volume space velocity 3.8h -1 , The reaction temperature is 143°C. After the reaction is finished, it enters the first adsorption dechlorination device 11 to adsorb and remove inorganic chlorides. The first adsorption dechlorination device 11 can be filled with a conventional industrial dechlorination agent, and its main component includes calcium oxide. The adsorption temperature of the adsorption dechlorination device is 140°C, and the adsorption pressure is 1.4MPa. Then the adsorbed and dechlorinated product enters the rectification tower 13 for rectific...

Embodiment 2

[0055] According to the scheme of the present invention, a new alkylation unit is built. After the alkylation reaction is completed, the ionic liquid is separated by the settling tank 6, and then the feed pump, the heat exchanger 7 and the hydrogen are fully mixed and dissolved in the SX type static mixer, and then enter the hydrodechlorination reactor 10. The reaction conditions For: reaction pressure 1.6MPa﹑liquid hour volume space velocity 4.2h -1, The reaction temperature is 157°C. After the reaction is finished, it enters the first adsorption dechlorination device 11 to adsorb and remove inorganic chlorides. The first adsorption dechlorination device 11 can be filled with a conventional industrial dechlorination agent, and its main components include magnesium oxide and the like. The adsorption temperature of the adsorption dechlorination device is 155°C, and the adsorption pressure is 1.5 MPa. Then the adsorbed and dechlorinated product enters the rectification tower ...

Embodiment 3

[0064] During the test operation, open the second valve 16 and the third valve 17 on the cross-line, and keep the second valve 16 and the third valve 17 at a small opening to simulate the internal leakage of the valve. (the first valve 15 is not opened), the chlorine content of the dechlorinated alkylate oil is greater than 10 ppm, but after the leak-proof pipeline is enabled (the first valve 15 is opened), the chlorine content of the dechlorinated alkylate oil is stable, as low as 1.0 ppm.

[0065] After calculation, under certain working conditions, when the catalyst performance is good (the product index is far lower than the control index), if there is 1.7wt% internal leakage, the chlorine content of the alkylate after dechlorination is greater than 10 ppm; In the later stage of use (the chlorine content of the alkylated oil after dechlorination is close to the quality index), if there is a slight internal leakage, the chlorine content of the product will not meet the stan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption temperature | aaaaa | aaaaa |

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com