Method for measuring setting time of building gypsum

A technology of setting time and building gypsum, which is applied in measuring devices, material analysis using sound waves/ultrasonic waves/infrasonic waves, and fluid analysis using sound waves/ultrasonic waves/infrasonic waves. To achieve the effect of accurate and rapid determination of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1) Weigh the water according to the standard consistency and pour the water into the mixing bowl. Weigh 300g of desulfurized gypsum clinker sample (the desulfurized gypsum is from Tieling Power Plant, and the clinker is calcined by Tieling Branch of Beixin Group Building Materials Co., Ltd.), pour it into water within 5s, and stir it with a mixing rod for 30s to obtain a uniform Slurry.

[0033] 2) Pour the slurry into the test barrel of an ultrasonic tester (produced by UltraTest GmbH, Germany, IP-8 ultrasonic measuring system), raise the test barrel by about 10mm, vibrate up and down 5 times, scrape off the overflow with a scraper, and use The surface of the slurry is flush with the upper end of the test bucket.

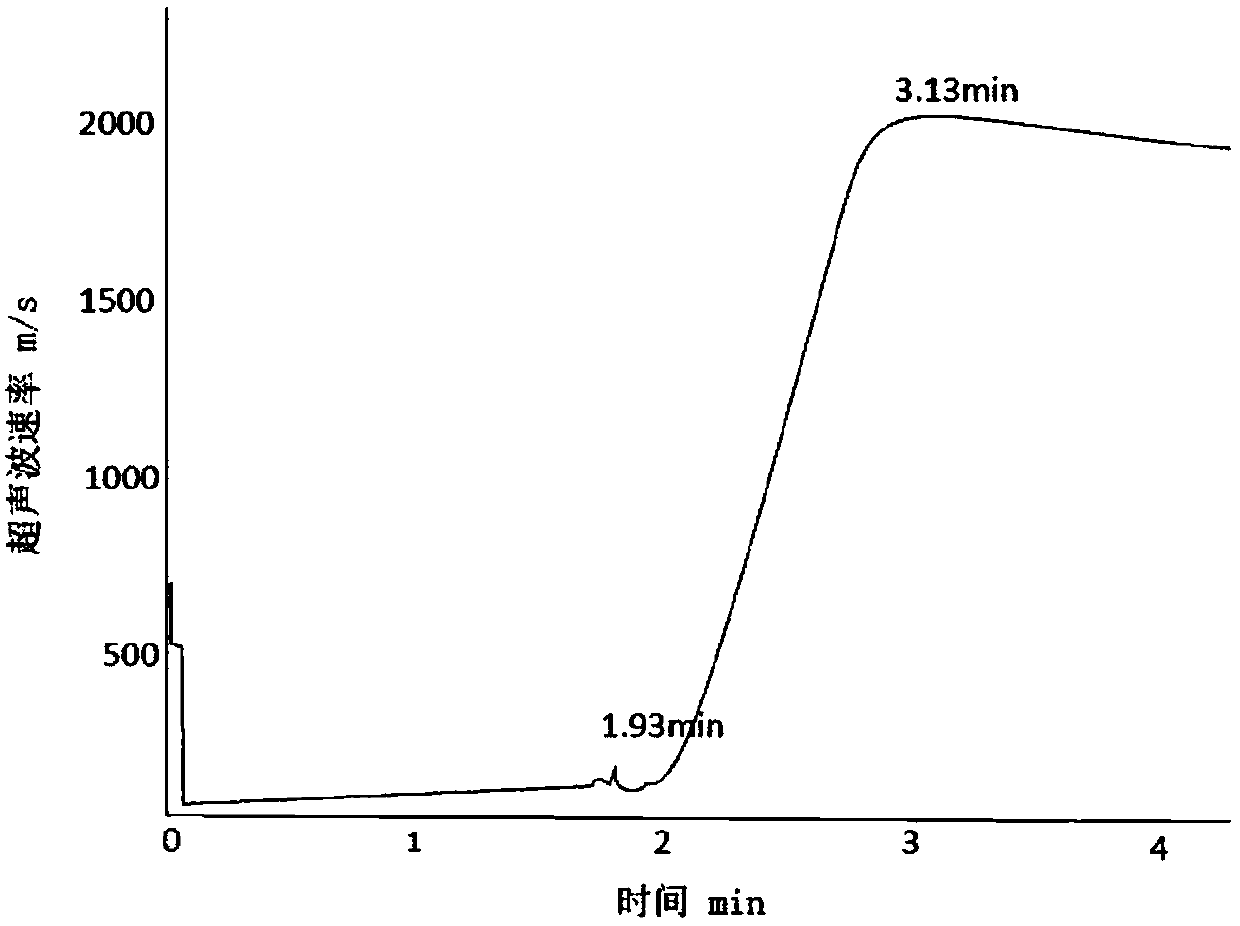

[0034] 3) Put the ultrasonic transmitting probe and receiving probe of the ultrasonic tester in contact with the slurry on opposite sides of the test barrel respectively, turn on the ultrasonic transmitter and receiver of the ultrasonic tester, and detect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com