Rice noodles and preparation method thereof

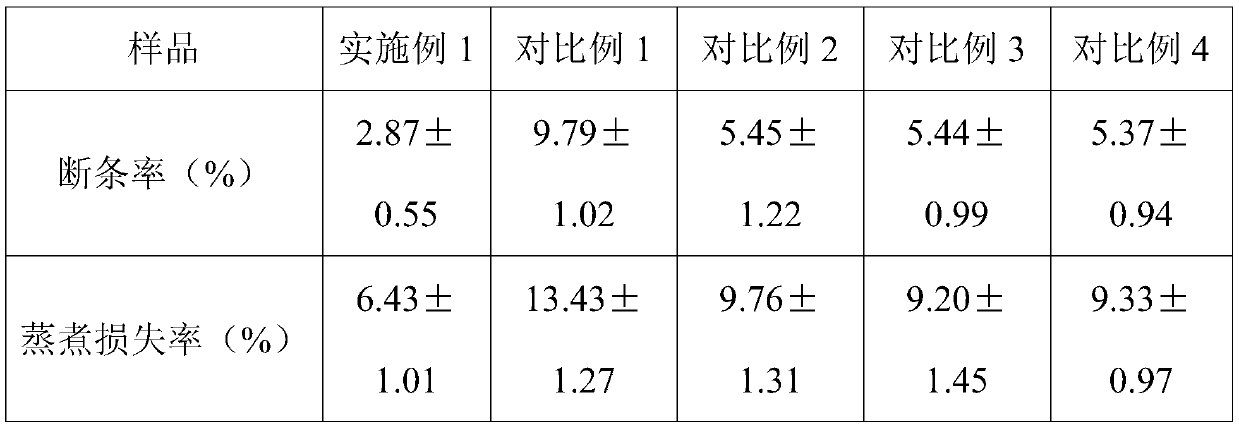

A technology of rice noodle and indica rice, applied in the field of rice noodle and its preparation, which can solve the problems of easy paste soup, high cooking loss rate, easy broken rice noodles, etc., and achieve not easy paste soup, avoid water pollution, broken bar rate and cooking loss rate low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A rice noodle is prepared from the following raw materials in parts by weight: 60 parts of indica rice flour, 25 parts of corn starch and 8 parts of wheat starch.

[0032] The preparation method of above-mentioned rice noodle, comprises the following steps:

[0033] (1) dry method prepares indica rice flour;

[0034] A: Raw material screening: Indica rice to be processed is obtained after removing stones and magnets from the indica rice;

[0035] B: Primary milling: grind the indica rice to be processed in the above step A with a stone mill with a temperature control device, the temperature of the grinding process is less than or equal to 40°C, and collect the indica rice flour after passing through a 115-mesh sieve;

[0036] C: secondary grinding: the raw material particles remaining on the sieve in the above step B are subjected to secondary grinding, the grinding process is the same as the above step B, passing through a 115 mesh sieve, and collecting the sieved ind...

Embodiment 2

[0047] A rice noodle is prepared from the following raw materials in parts by weight: 50 parts of indica rice flour, 20 parts of corn starch and 5 parts of wheat starch.

[0048] The preparation method of above-mentioned rice noodle, comprises the following steps:

[0049] (1) dry method prepares indica rice flour;

[0050] A: Raw material screening: Indica rice to be processed is obtained after removing stones and magnets from the indica rice;

[0051] B: Primary milling: grind the indica rice to be processed in the above step A with a stone mill with a temperature control device, the temperature of the grinding process is less than or equal to 40°C, and collect the indica rice flour after passing through a 118-mesh sieve;

[0052] C: secondary grinding: the raw material particles remaining on the sieve in the above step B are subjected to secondary grinding, the grinding process is the same as the above step B, passing through a 118 mesh sieve, and collecting the sieved ind...

Embodiment 3

[0063] A rice noodle is prepared from the following raw materials in parts by weight: 80 parts of indica rice flour, 30 parts of corn starch and 10 parts of wheat starch.

[0064] The preparation method of above-mentioned rice noodle, comprises the following steps:

[0065] (1) dry method prepares indica rice flour;

[0066] A: Raw material screening: Indica rice to be processed is obtained after removing stones and magnets from the indica rice;

[0067] B: Primary milling: grind the indica rice to be processed in the above step A with a stone mill with a temperature control device, the temperature of the grinding process is less than or equal to 40°C, and collect the indica rice flour after passing through a 120-mesh sieve;

[0068] C: secondary grinding: the raw material particles remaining on the sieve in the above step B are subjected to secondary grinding, the grinding process is the same as the above step B, passing through a 120 mesh sieve, and collecting the sieved in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com