Simple abnormally-shaped test piece clamp and clamping method

A special-shaped and test piece technology, which is applied in the direction of manufacturing tools, grinding workpiece supports, grinding machine parts, etc. and other problems, to achieve the effect of small deformation of the device, small wear, and ensure the flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

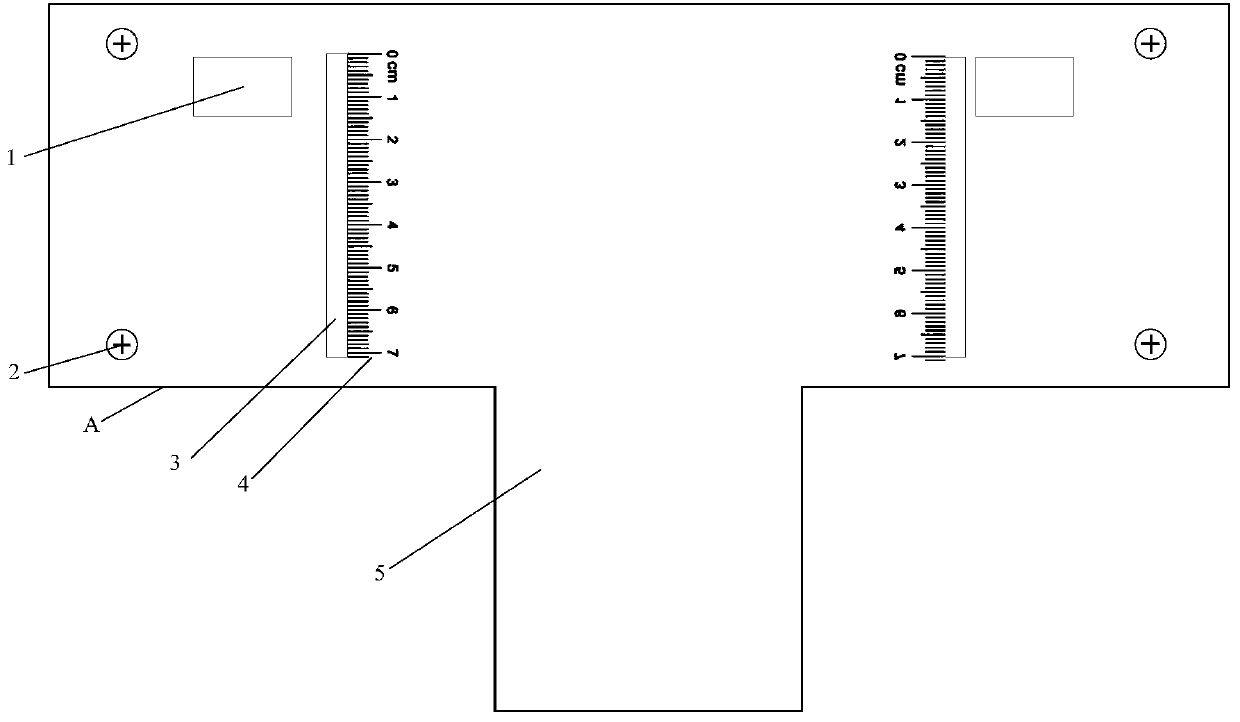

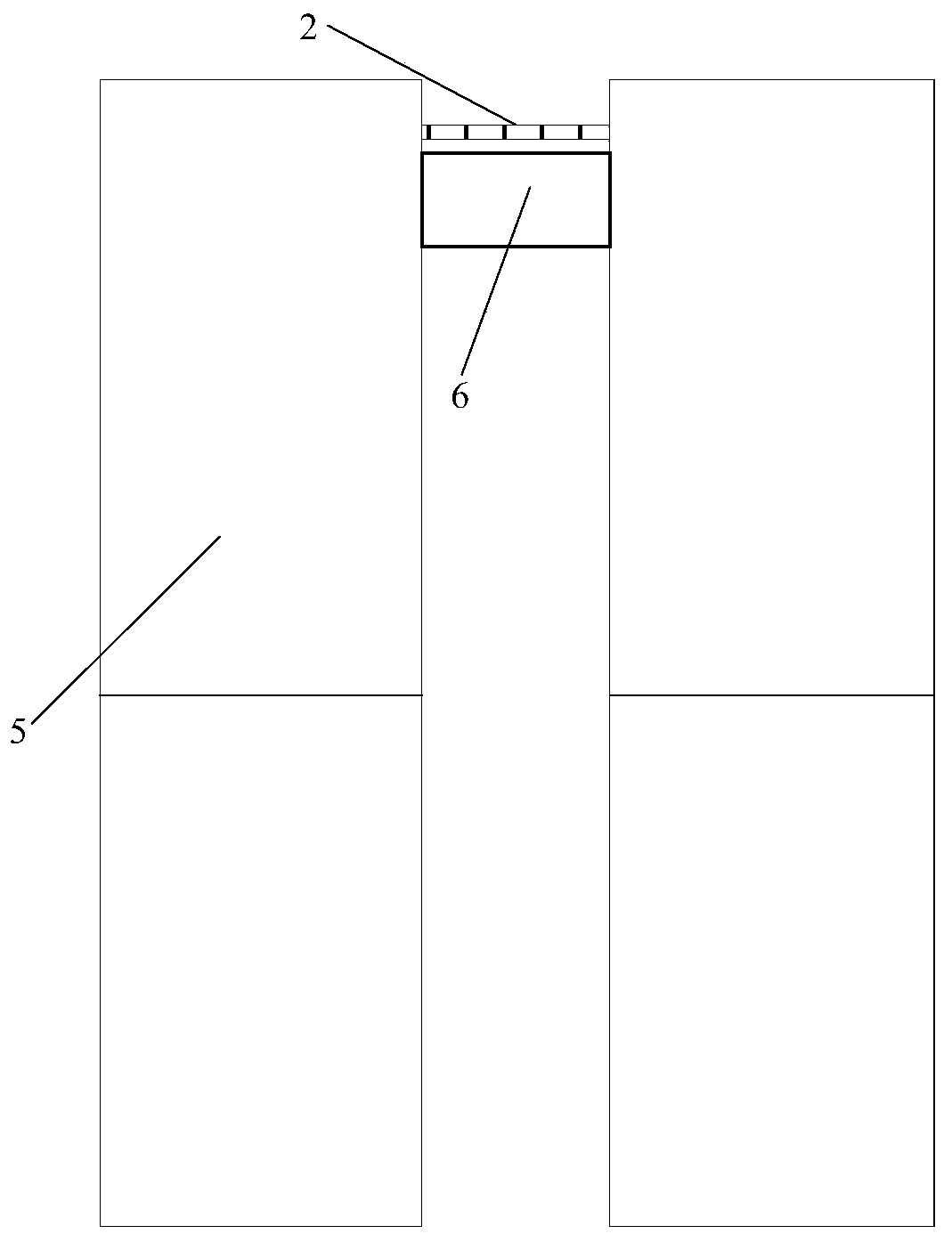

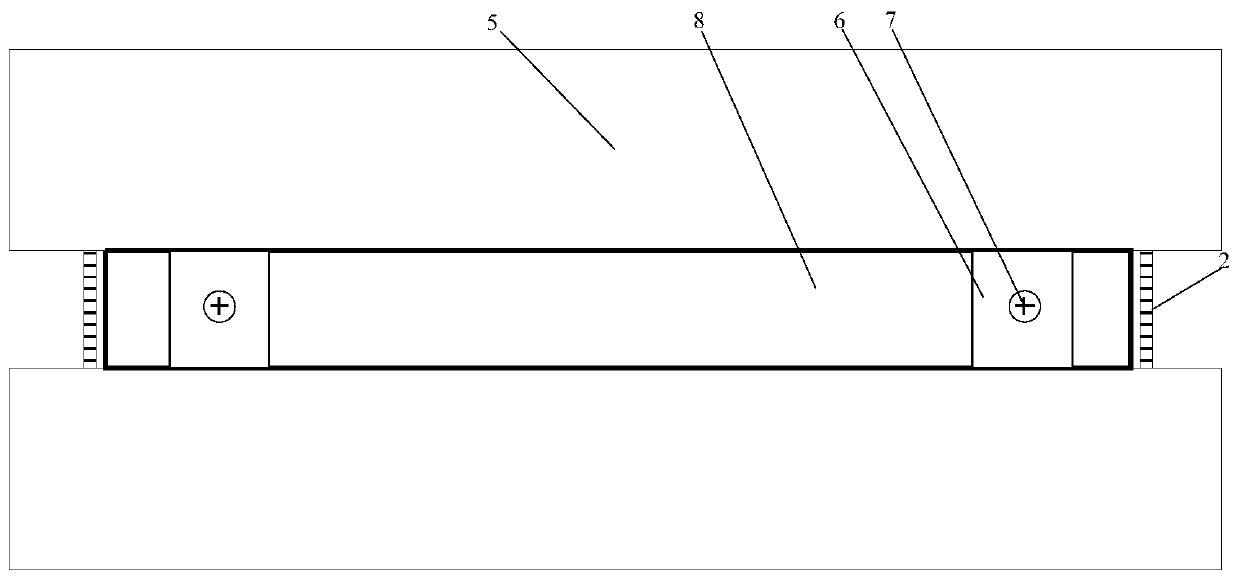

[0034] see figure 1 — Figure 12 , in order to recycle the lapped test piece, save the cost of the experiment, facilitate the grinding of the special-shaped test piece, ensure the smoothness of the polished surface of the test piece, ensure the accuracy of the test data, and provide an effective guarantee for the packaging test. The invention proposes a set of simple special-shaped test piece clamps for special-shaped overlapping test pieces, and the device can also be used for grinding conventional test pieces.

[0035] A set of simple clamping devices for special-shaped test pieces proposed by the present invention includes: two T-shaped clamps, four fixing bolts, two limiting bolts, two limiting plates, and a parallel plate. Among them, two observation holes are set on one of the T-shaped fixtures. The top of the observation hole is parallel to the bottom of the limit plate and the top of the parallel plate. The limit plate is inserted into the reserved limit plate hole of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com