Automatic and rapid spiral location device for crankshaft, and use method thereof

A technology for positioning devices and crankshafts, applied to workpiece clamping devices, use feedback control, hand-held tools, etc., can solve the problems of high labor intensity and low work efficiency, achieve reduced labor intensity, good device versatility, and improved The effect of docking accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

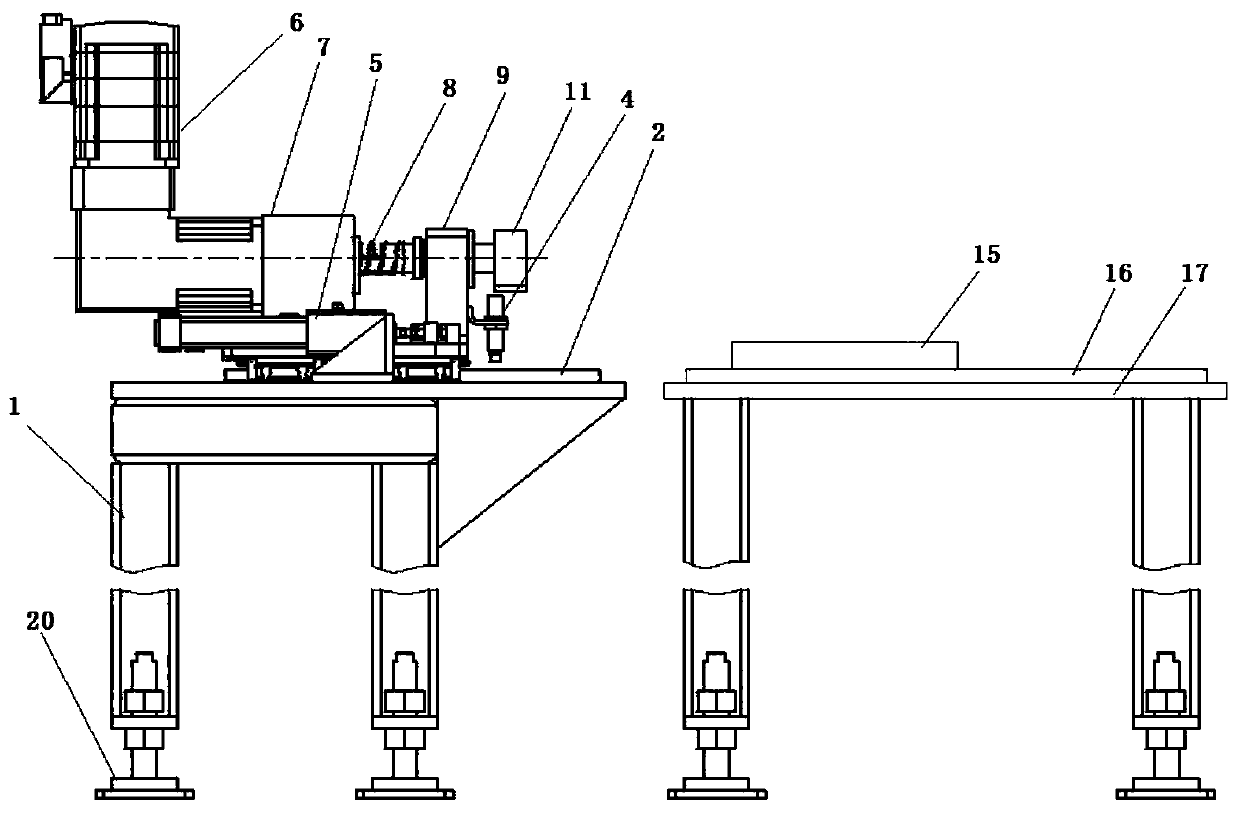

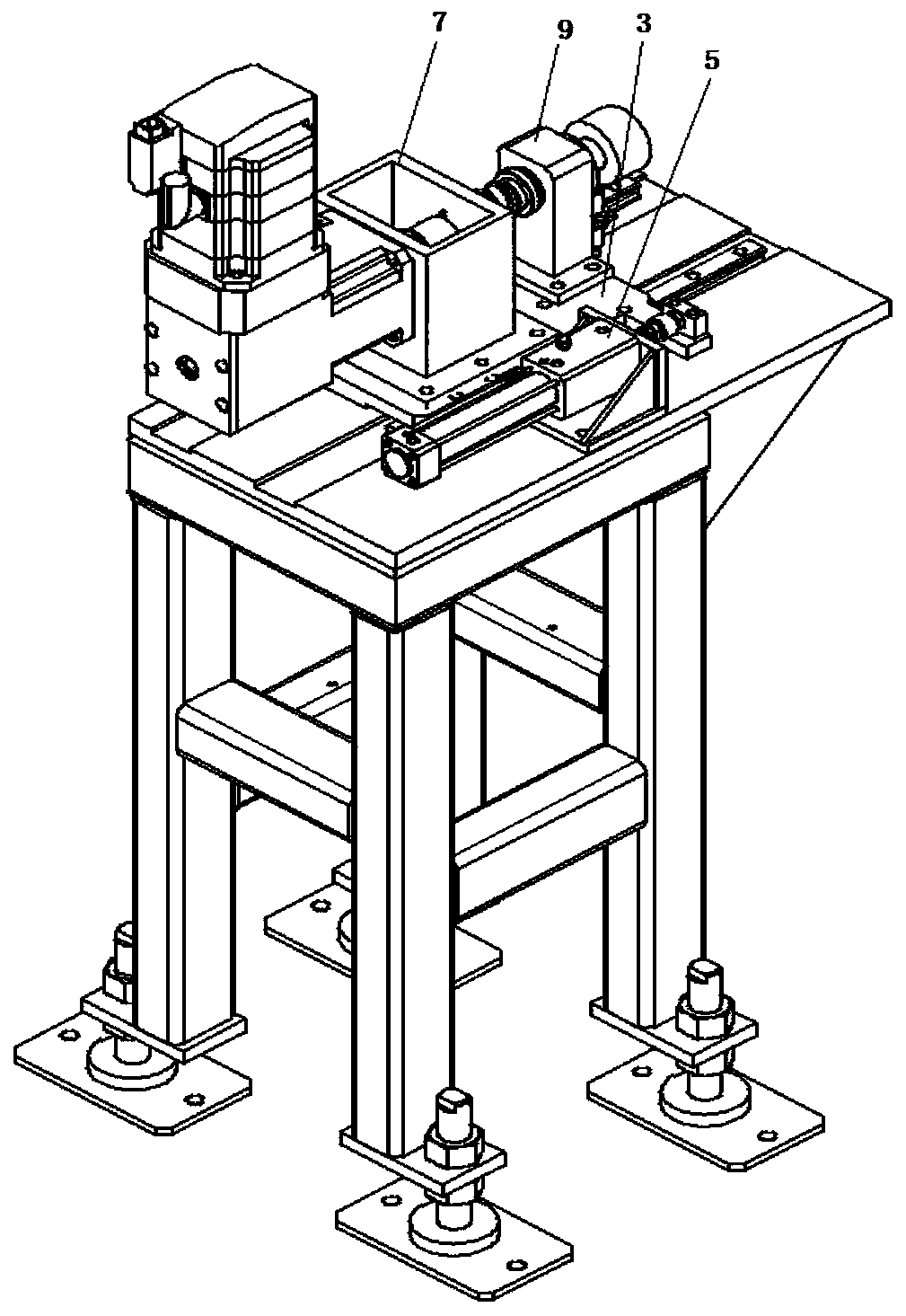

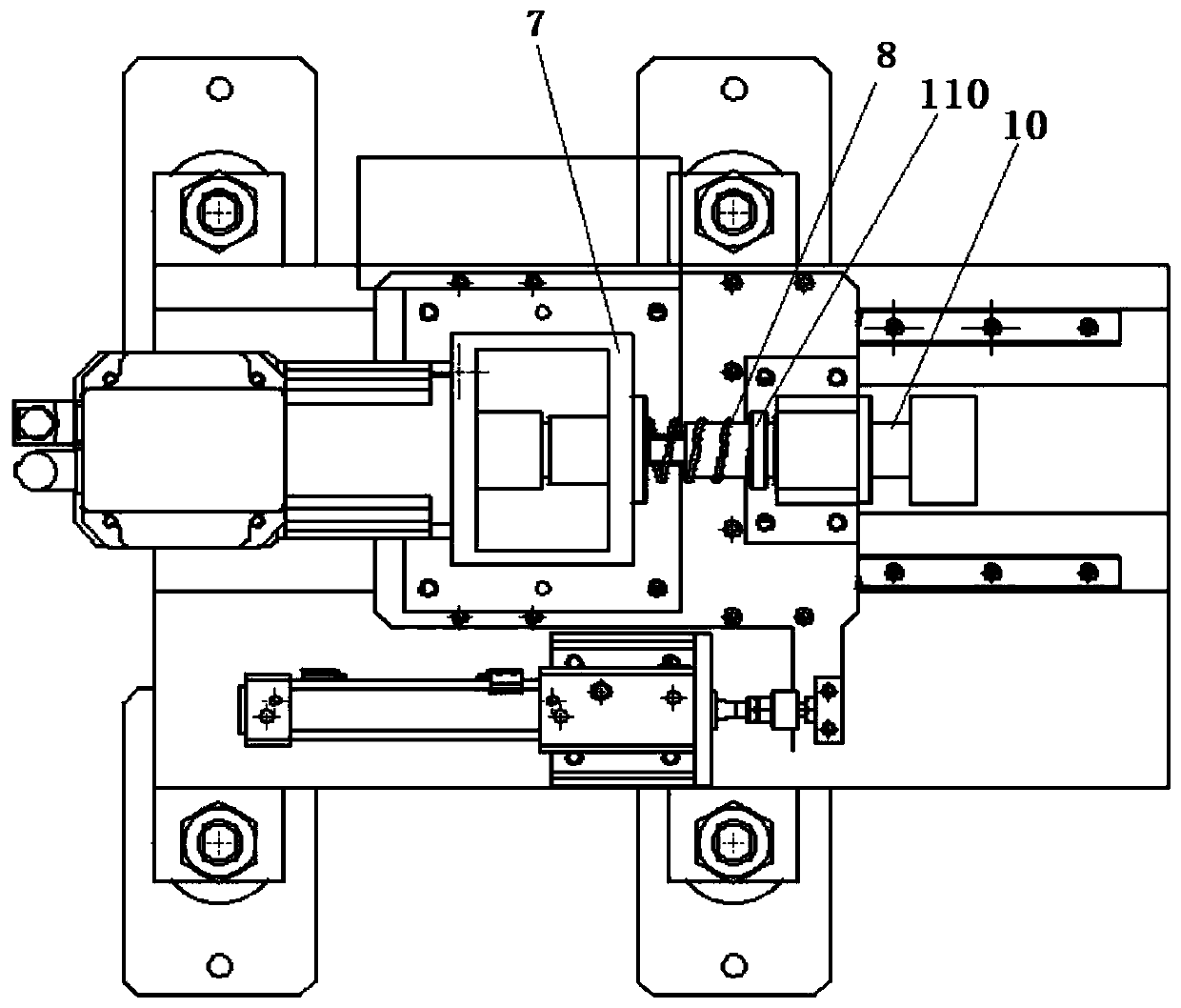

[0034] Such as Figure 1-6 The shown automatic and rapid crankshaft rotation positioning device includes a rotation mechanism and an assembly slide for fixing the engine arranged on the right side of the rotation mechanism. The hovering mechanism includes a support platform 1, a mounting plate 3, a cylinder 5, a support base 7, and a proximity switch 4. The mounting plate 3 is slidably connected with the upper surface of the support platform 1 through a sliding assembly, and is connected to the upper surface of the support platform 1 through the cylinder 5. The telescopic displacement drives the mounting plate 3 to reciprocate on the sliding device. The lower end of the supporting seat 7 is fixedly connected with the mounting plate 3 , and the upper end is provided with a servo motor 6 and a telescopic rotating shaft 10 connected with the servo motor shaft. The telescopic rotating shaft 10 is affected by the elastic member, so that it shrinks under the elastic force of the el...

Embodiment 2

[0047] The only difference between this embodiment and the first embodiment is that two square bosses 19 are arranged on the right end of the first connection base 11 , and the two square bosses 19 are one large and one small. Two bosses 19 of different sizes are provided to improve the linkage stability between the first connecting seat 11 and the second connecting seat, and at the same time, when the boss is aligned with the positioning square groove, it can be quickly inserted into the positioning square groove.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com