Power joint device and lower limb power-assisted equipment

A power device and joint technology, applied in the field of wearable devices, can solve the problems of poor structural rigidity, difficult to guarantee, and high cost, and achieve the effects of wide selection adaptability, simplified design complexity, and improved morphological performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

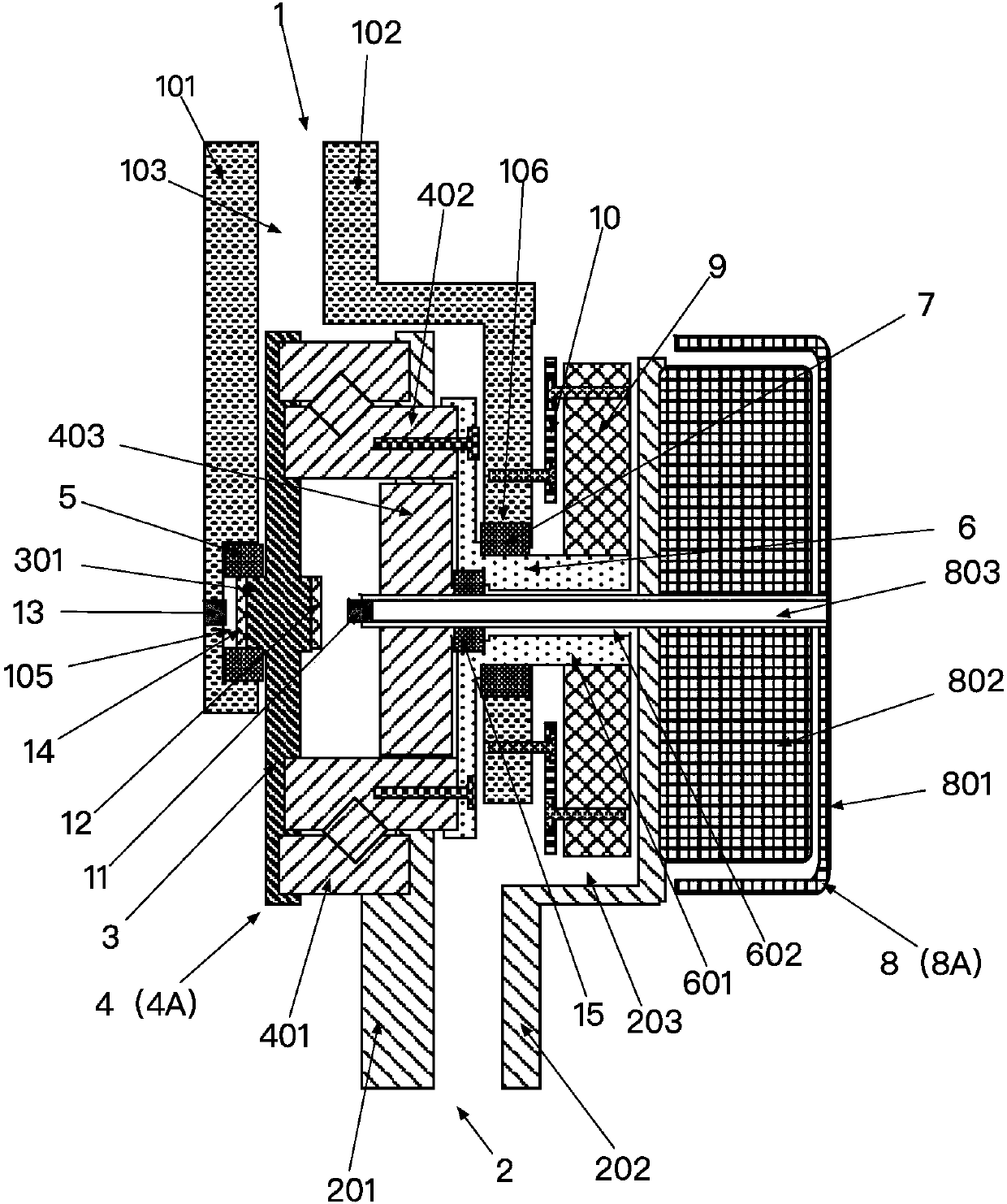

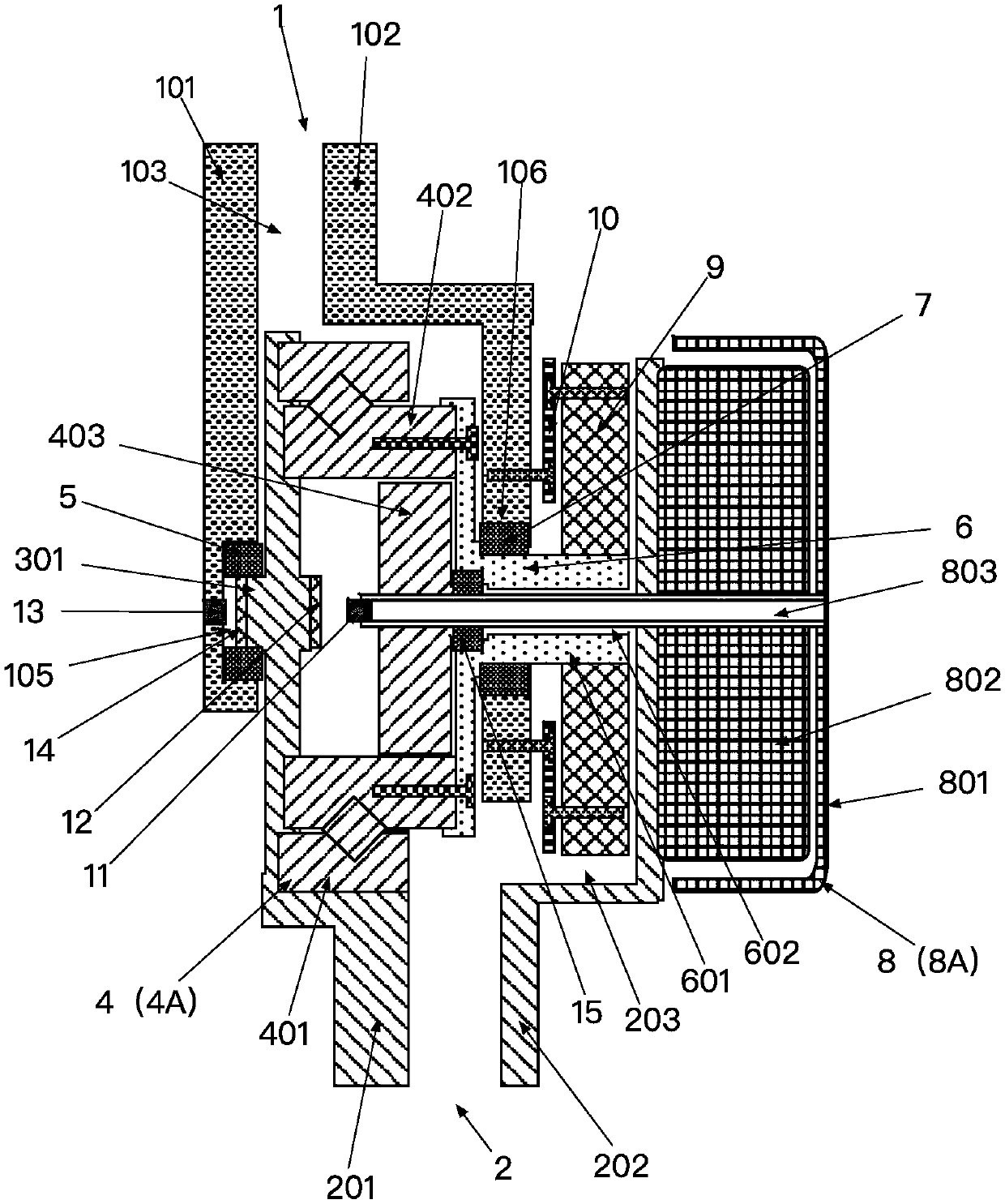

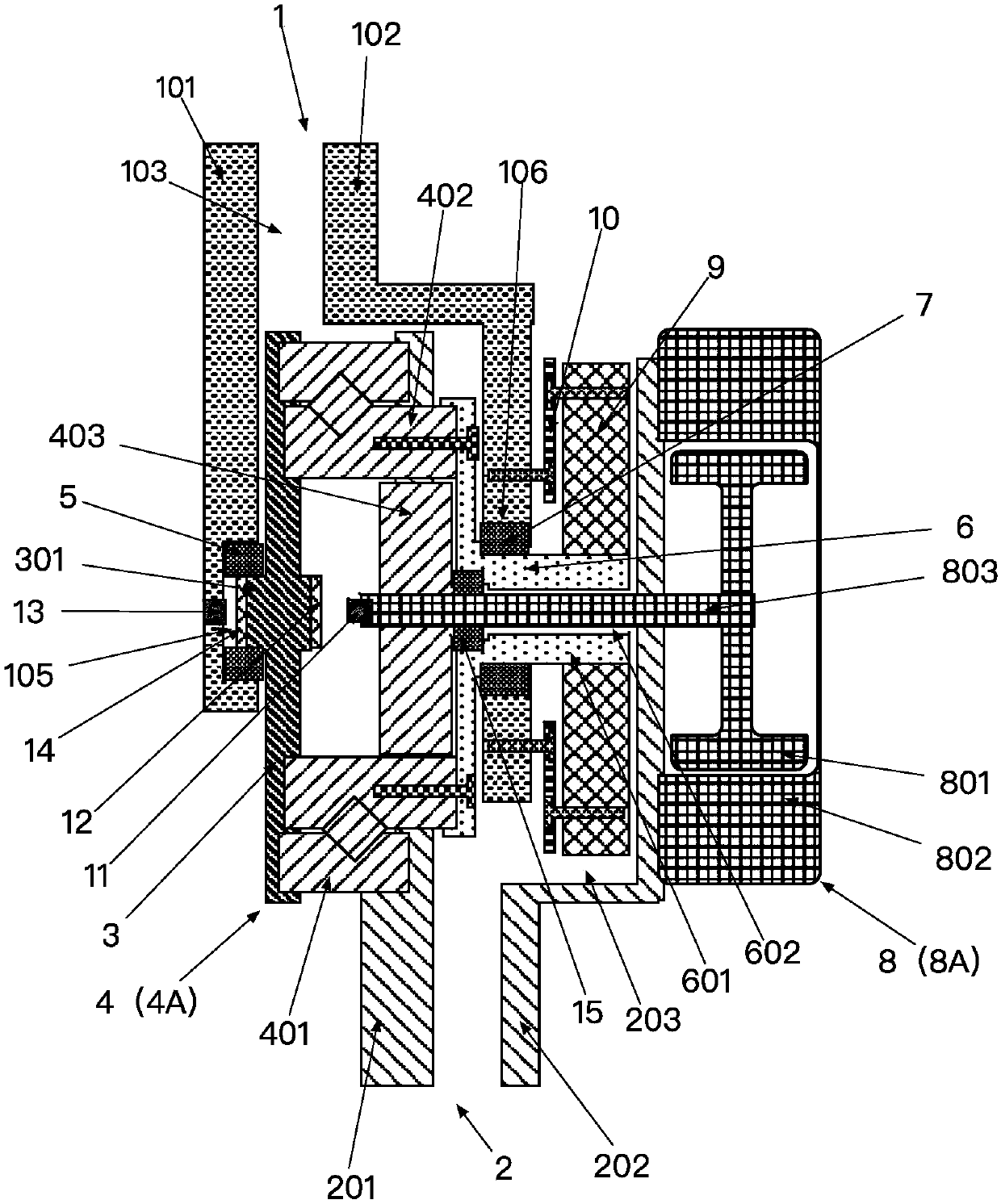

[0041] Such as figure 1 — Figure 8 Shown is a specific structural view of an embodiment of a portable dynamic joint device of the present invention.

[0042] A powered joint device such as figure 1 — image 3 As shown, it includes a joint body 1001 and a power device disposed on the joint body 1001 . The joint body 1001 includes an upper arm 1 and a lower arm 2 that moves relative to the upper arm 1 . The power device includes a power part 8A, and a reduction mechanism 4A fixed at the power output end of the power part 8A. The power part 8A is fixed on the lower arm 2, and the power output end of the reduction mechanism 4A is connected with the upper arm 1, so that the power part 8A drives the upper arm 1 to move relative to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com