Intelligent vacuum circulating propulsion grouting system

A technology of vacuum circulation and circulation system, which is applied in the direction of control devices, mixing plants, clay preparation devices, etc., can solve the problems of increased manufacturing difficulty, increased cost, poor measurement accuracy of weighing sensors, etc., to reduce uncertainty, maintain and clean Convenience and the effect of reducing the installation height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

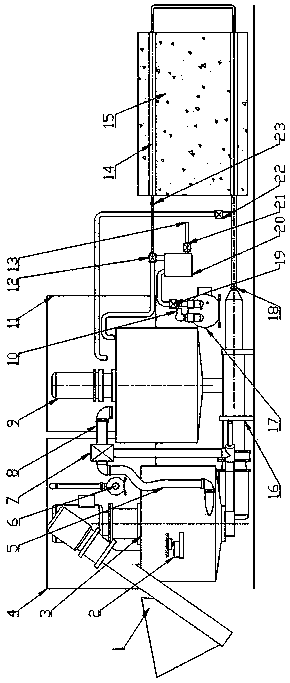

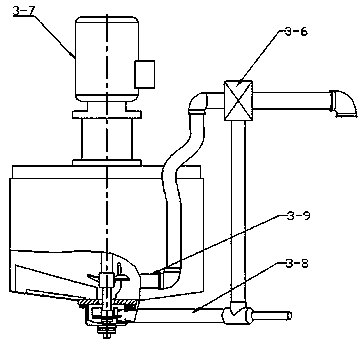

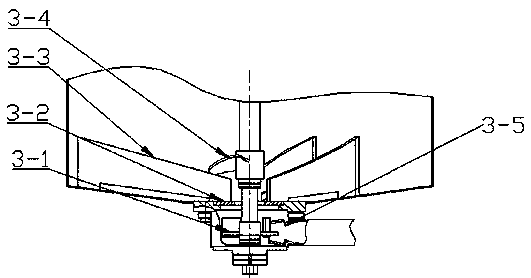

[0015] like figure 1 As shown, this embodiment includes an auger feeder 1, a load cell 2, a push-type high-speed circulation system 3, a water tank 4, a slurry return pipe 5, a water pump 6, a three-way reversing valve 7, a slurry outlet 8, a low-speed Mixing barrel system 9, sewage outlet 10, electrical control system 11 three-way vacuum valve 12, sewage outlet 13, slurry return pipe 14, prestressed beam 15, screw pump 16, vacuum pump 17, slurry outlet 18, air intake valve 19, Vacuum tank 20, blowdown valve 21, mud special overflow valve 22, slurry return port 23, and data storage and transmission system, the system realizes fully automatic pulping, guarantees the quality of slurry, and at the same time the slurry output and holding pressure It is stable and can detect the amount of grouting to ensure that the grout in the tunnel is full, automatically record the data of the grouting process, the system has a high degree of automation, and reduces the uncertainty of manual in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com