Wear-resistant anti-reflection transparent heat-insulating glass and preparation method thereof

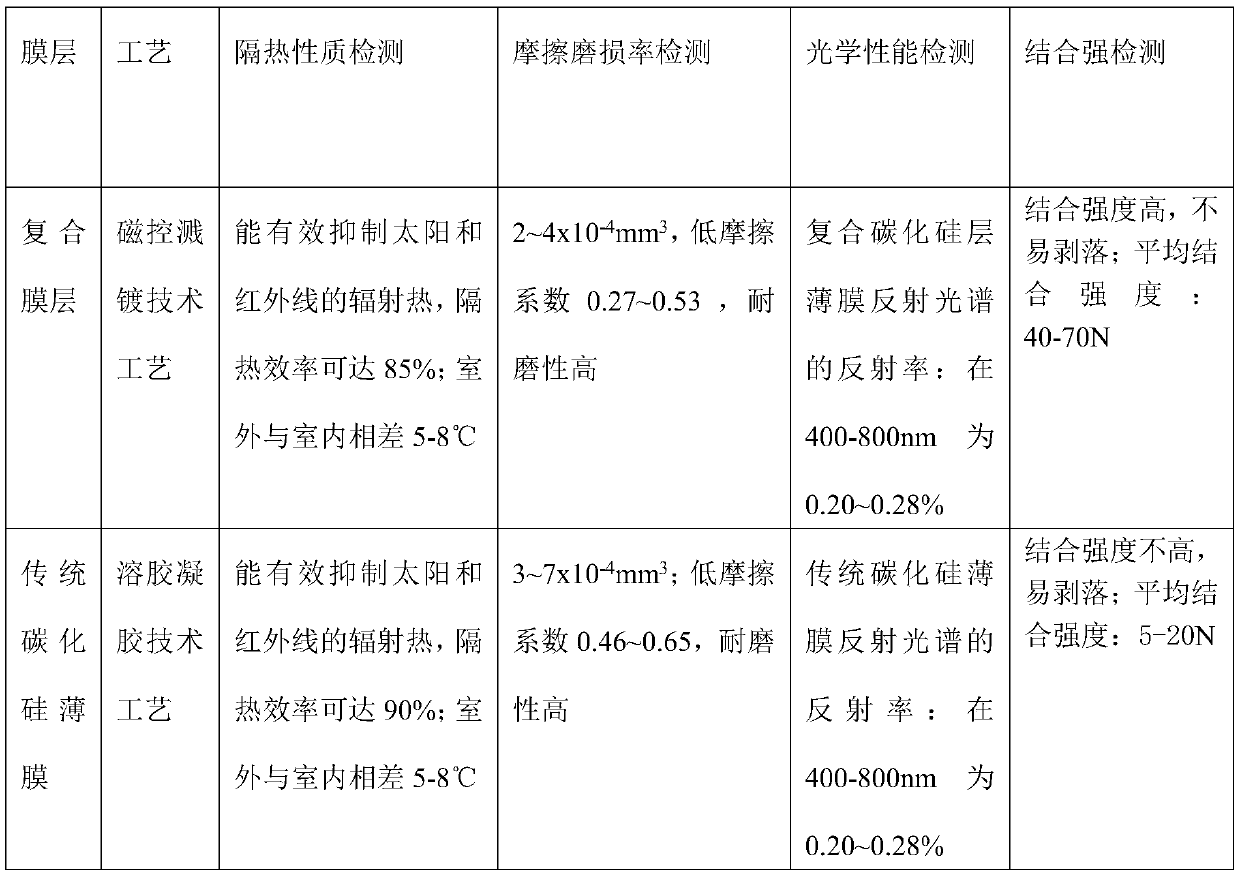

An insulating glass and anti-reflection technology, which is applied in the fields of transparent insulating glass and its preparation, wear resistance and anti-reflection, and achieves the effects of good transparency, good heat insulation and broad market prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

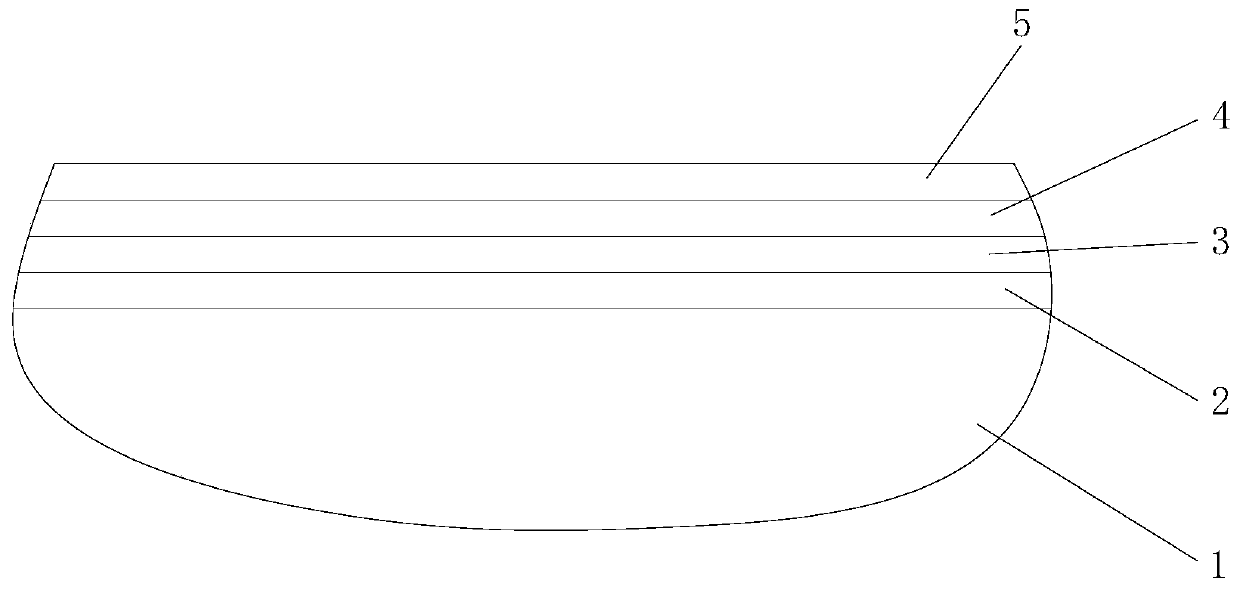

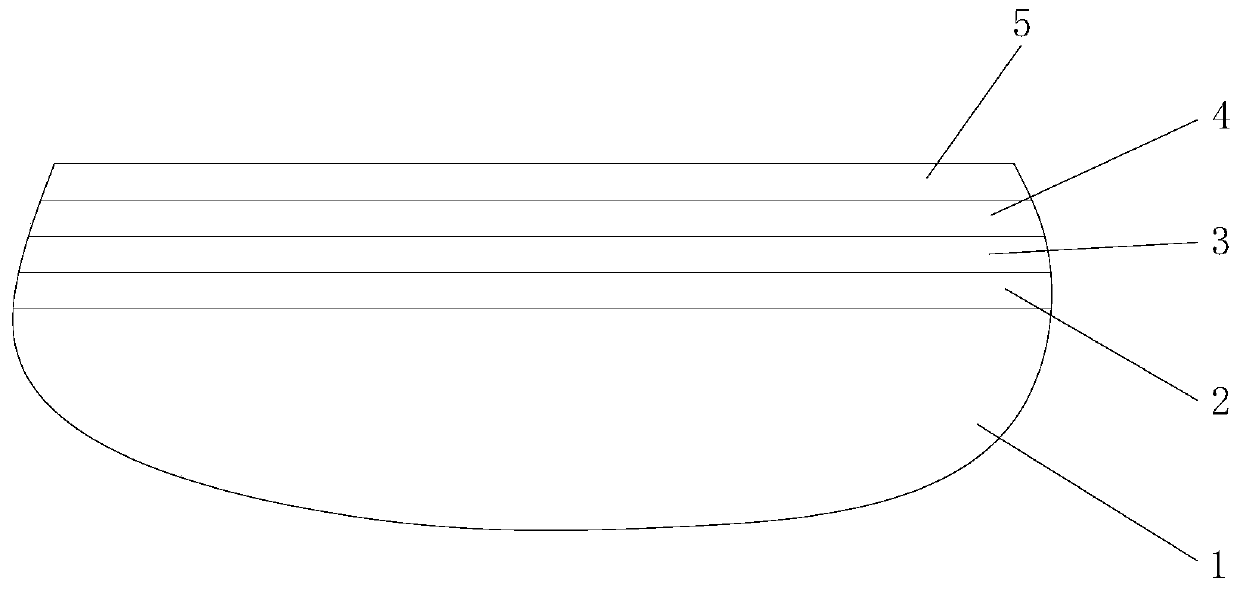

Image

Examples

Embodiment 1

[0028] Embodiment 1: The preparation method of the wear-resistant, anti-reflection, transparent heat-insulating glass of the present invention comprises the following steps:

[0029] 1) Surface treatment of the substrate: the substrate was ultrasonically cleaned in deionized water and ethanol for 30 min respectively, and then dried with nitrogen.

[0030] 2) Prepare the inner layer: send the substrate into the coating chamber, use radio frequency magnetron sputtering to form the ZnO layer, use DC power supply, sputtering power 100W, Ar gas as the protective gas, ZnO as the target, ZnO target current 4A, Ar gas flow 100sccm, substrate revolution 2rpm, sputtering time 10min, distance between ZnO target and substrate 40mm;

[0031] 3) Preparation of the first transition layer: Continue radio frequency magnetron sputtering to form a 30wt% SiC+70wt% ZnO layer (the mass ratio of SiC to ZnO is: 30wt%: 70wt%), using DC power supply, sputtering power 100W, Ar gas As protective gas, Zn...

Embodiment 2

[0034]Embodiment 2: The preparation method of the wear-resistant, anti-reflection, transparent heat-insulating glass of the present invention comprises the following steps:

[0035] 1) Surface treatment of the substrate: the substrate was ultrasonically cleaned in deionized water and ethanol for 30 min respectively, and then dried with nitrogen.

[0036] 2) Prepare the inner layer: send the substrate into the coating chamber, use radio frequency magnetron sputtering to form the ZnO layer, use DC power supply, sputtering power 200W, Ar gas as the protective gas, ZnO as the target, ZnO target current 8A, Ar gas flow rate 200sccm, substrate revolution 4rpm, sputtering time 30min, distance between ZnO target and substrate 80mm;

[0037] 3) Preparation of the first transition layer: Continue radio frequency magnetron sputtering to form a 30wt% SiC+70wt% ZnO layer (the mass ratio of SiC to ZnO is: 30wt%: 70wt%), using DC power supply, sputtering power 200W, Ar gas As protective gas...

Embodiment 3

[0040] Embodiment 3: The preparation method of the wear-resistant, anti-reflection, transparent heat-insulating glass of the present invention comprises the following steps:

[0041] 1) Surface treatment of the substrate: the substrate was ultrasonically cleaned in deionized water and ethanol for 30 min respectively, and then dried with nitrogen.

[0042] 2) Prepare the inner layer: send the substrate into the coating chamber, use radio frequency magnetron sputtering to form the ZnO layer, use DC power supply, sputtering power 150W, Ar gas as the protective gas, ZnO as the target, ZnO target current 6A, Ar gas flow rate 150sccm, substrate revolution 3rpm, sputtering time 20min, distance between ZnO target and substrate 60mm;

[0043] 3) Preparation of the first transition layer: Continue radio frequency magnetron sputtering to form a 30wt% SiC+70wt% ZnO layer (the mass ratio of SiC to ZnO is: 30wt%: 70wt%), using DC power supply, sputtering power 150W, Ar gas As protective ga...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com