Design and construction method of side face formworks of thick and large concrete structures

A technology of concrete structure and construction method, which is applied in the direction of basic structure engineering, formwork/formwork/work frame, building structure, etc., and can solve problems such as long construction period, insufficient rigidity, and difficult construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

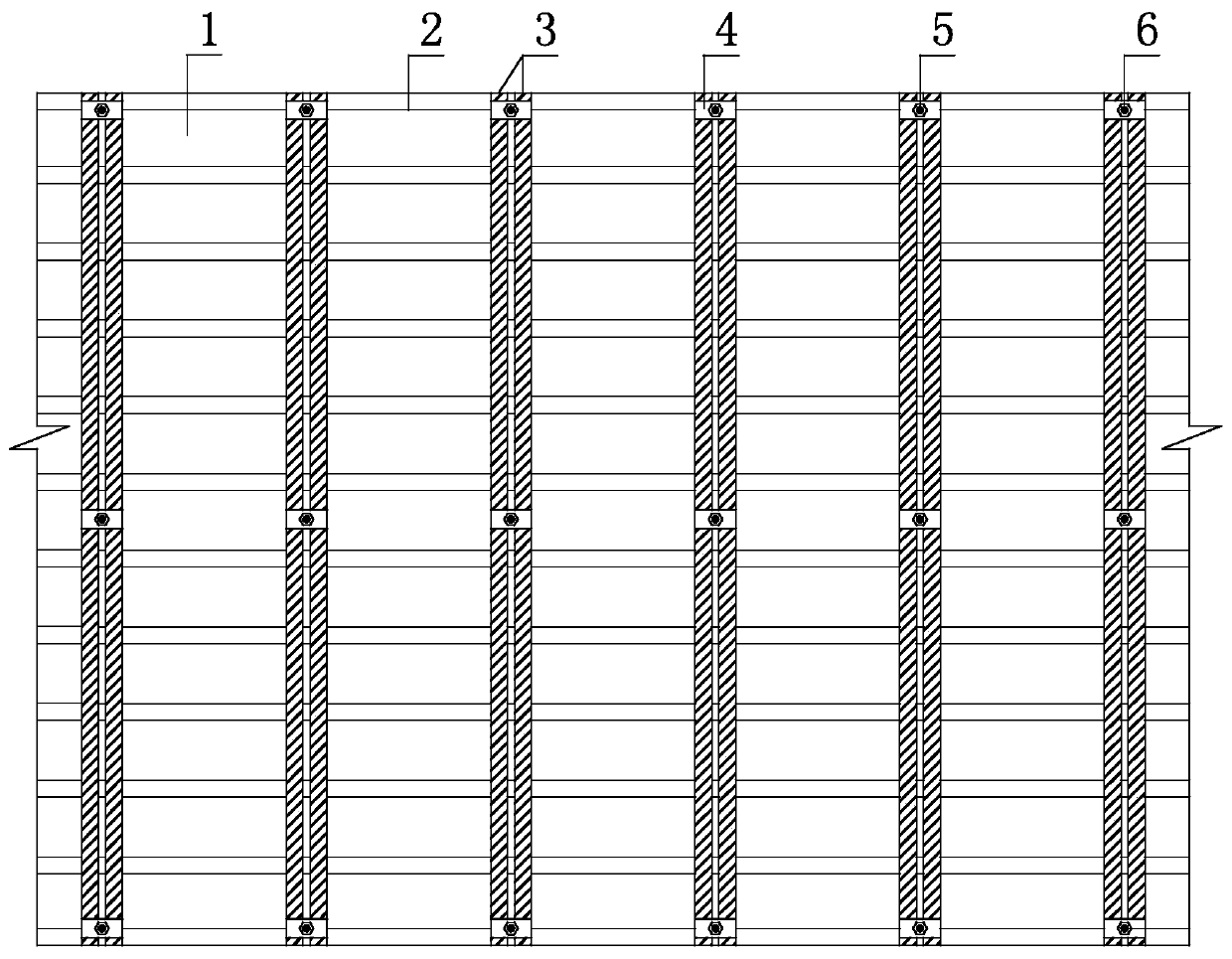

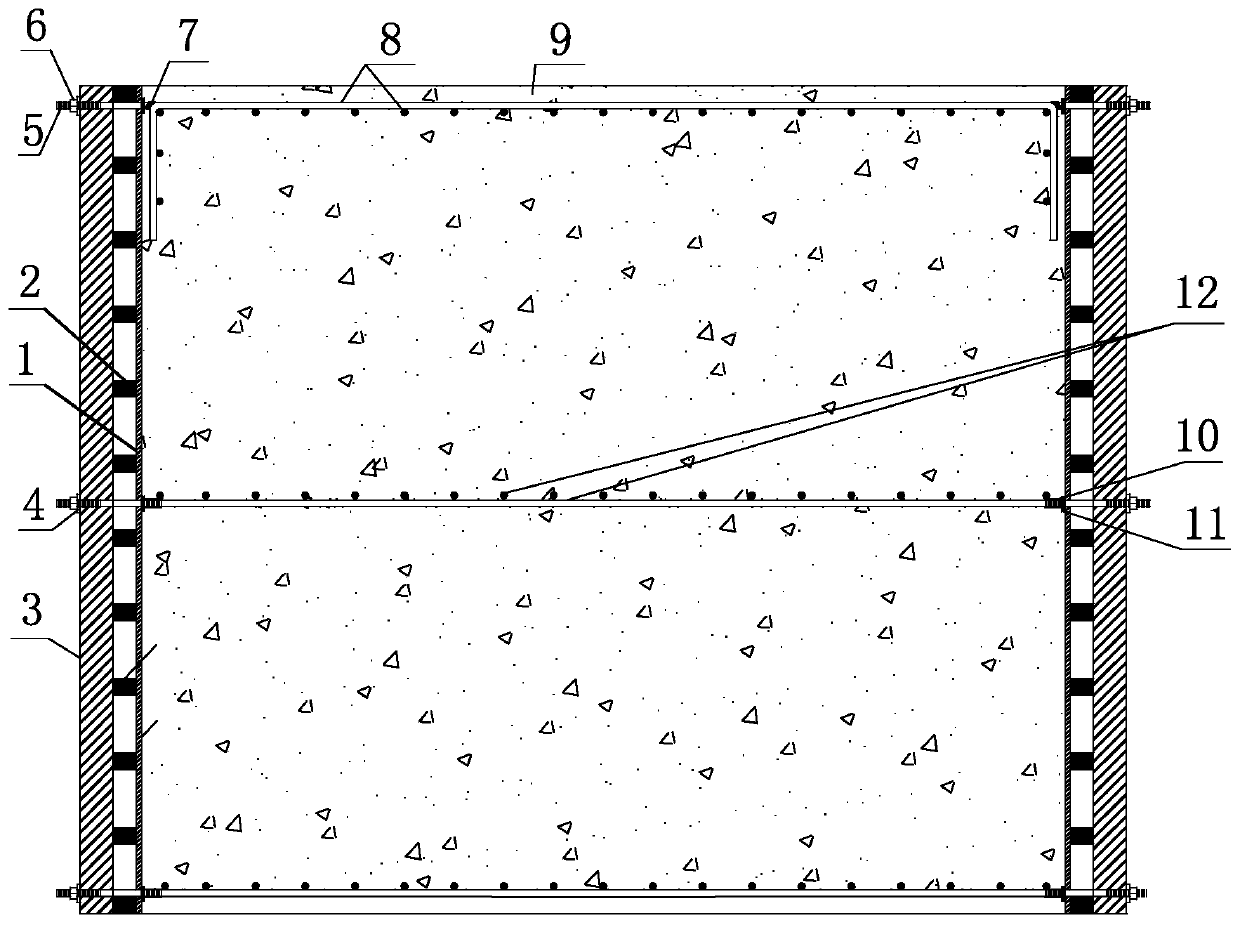

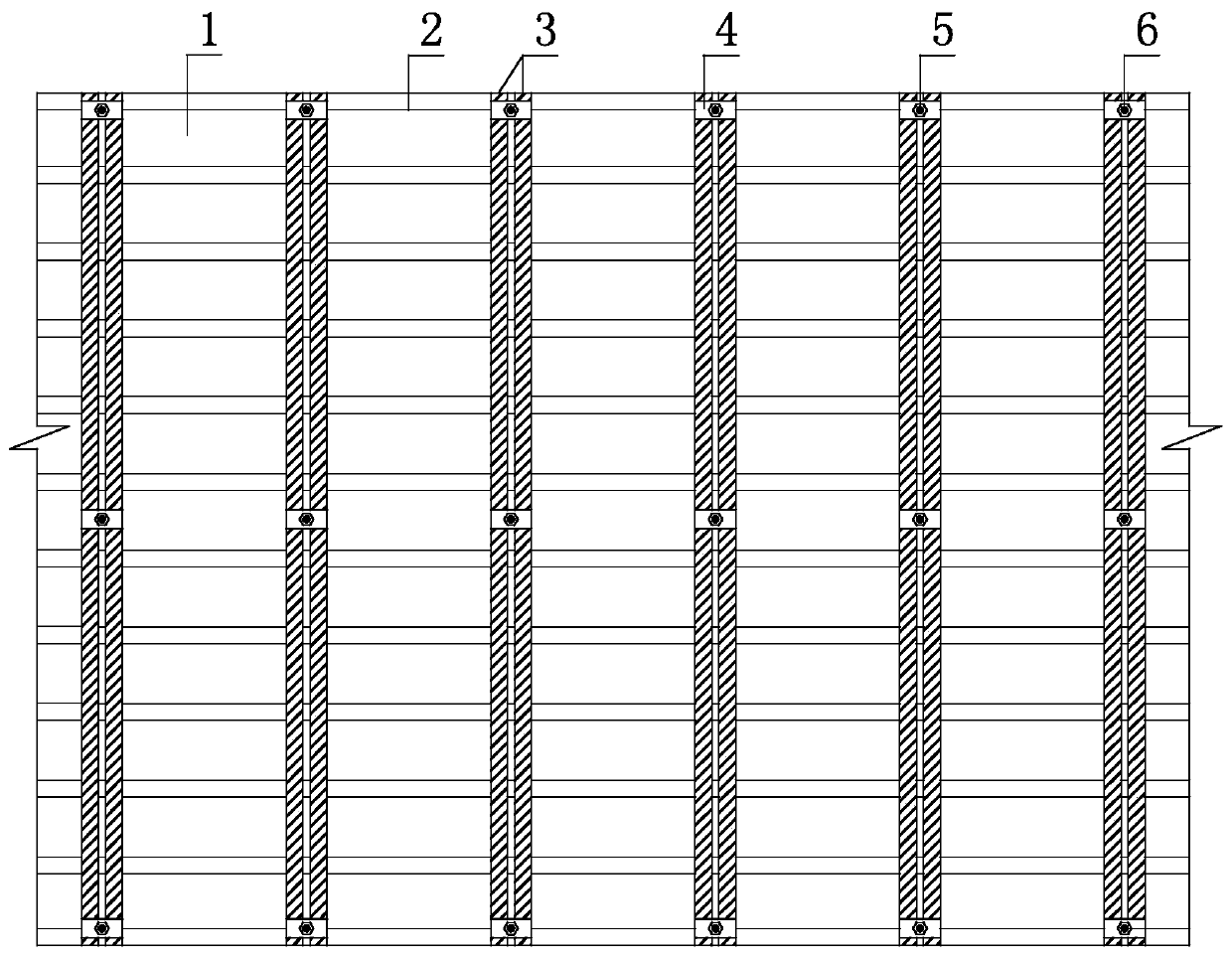

[0215] Such as Figure 1-2 As shown, the design and construction method of the thick concrete structure side formwork described in this embodiment, take the following steps:

[0216] 1. Determine the formwork system calculation model:

[0217] 1.1. Determine the layout direction and spacing of secondary flute 2 and main flute 3:

[0218] The secondary flute 2 is arranged horizontally with a spacing of 200㎜~250㎜; the main flute 3 is arranged vertically with a spacing of 400~600㎜, which is consistent with the multiple of the horizontal spacing of structural steel bars;

[0219] 1.2. Determine the calculation model of Panel 1:

[0220] The panel 1 takes the second corrugated 2 as the support, and the calculation model is determined according to the continuous beam with three spans and equal spans;

[0221] 1.3. Determine the calculation model of second flute 2:

[0222] The secondary flute 2 takes the main flute 3 as the support, and the calculation model is determined accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com