Tunnel digging-out supporting structure and construction method thereof

A construction method and technology for supporting structures, which are applied in tunnels, tunnel linings, and earth-moving drilling and mining, etc., can solve problems such as economic losses in tunnels, and achieve the effects of solving the difficulty of transporting construction personnel and equipment, reducing investment increases, and ensuring construction safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

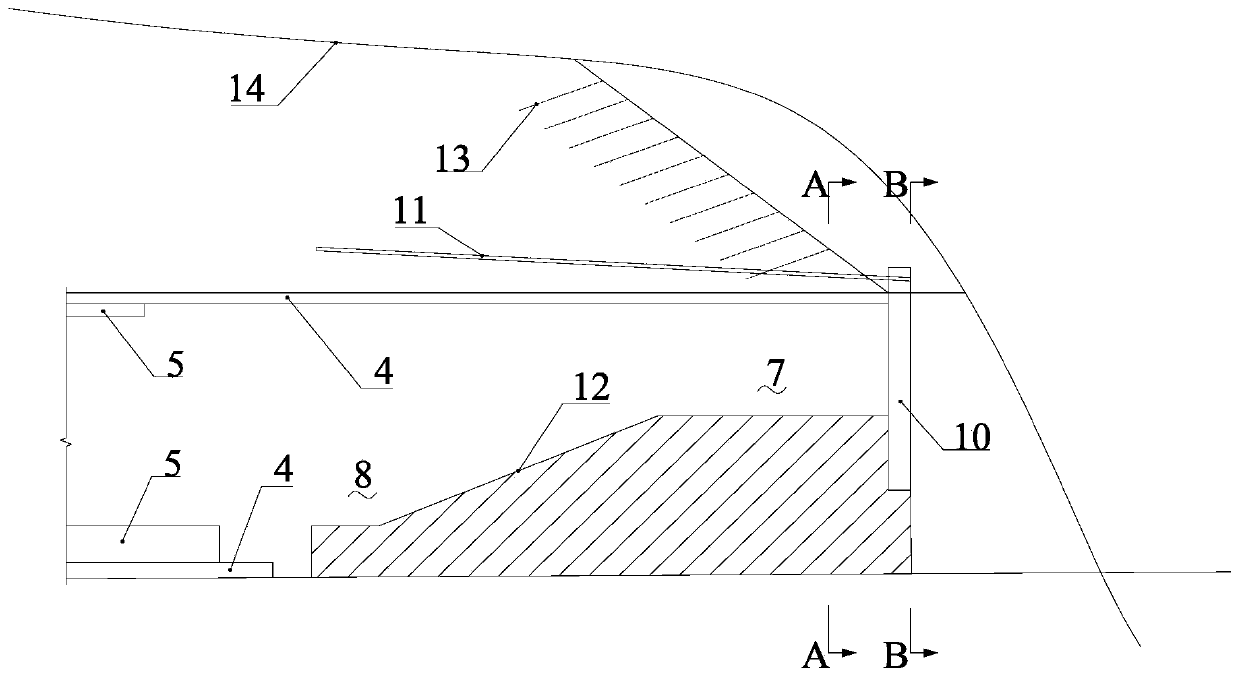

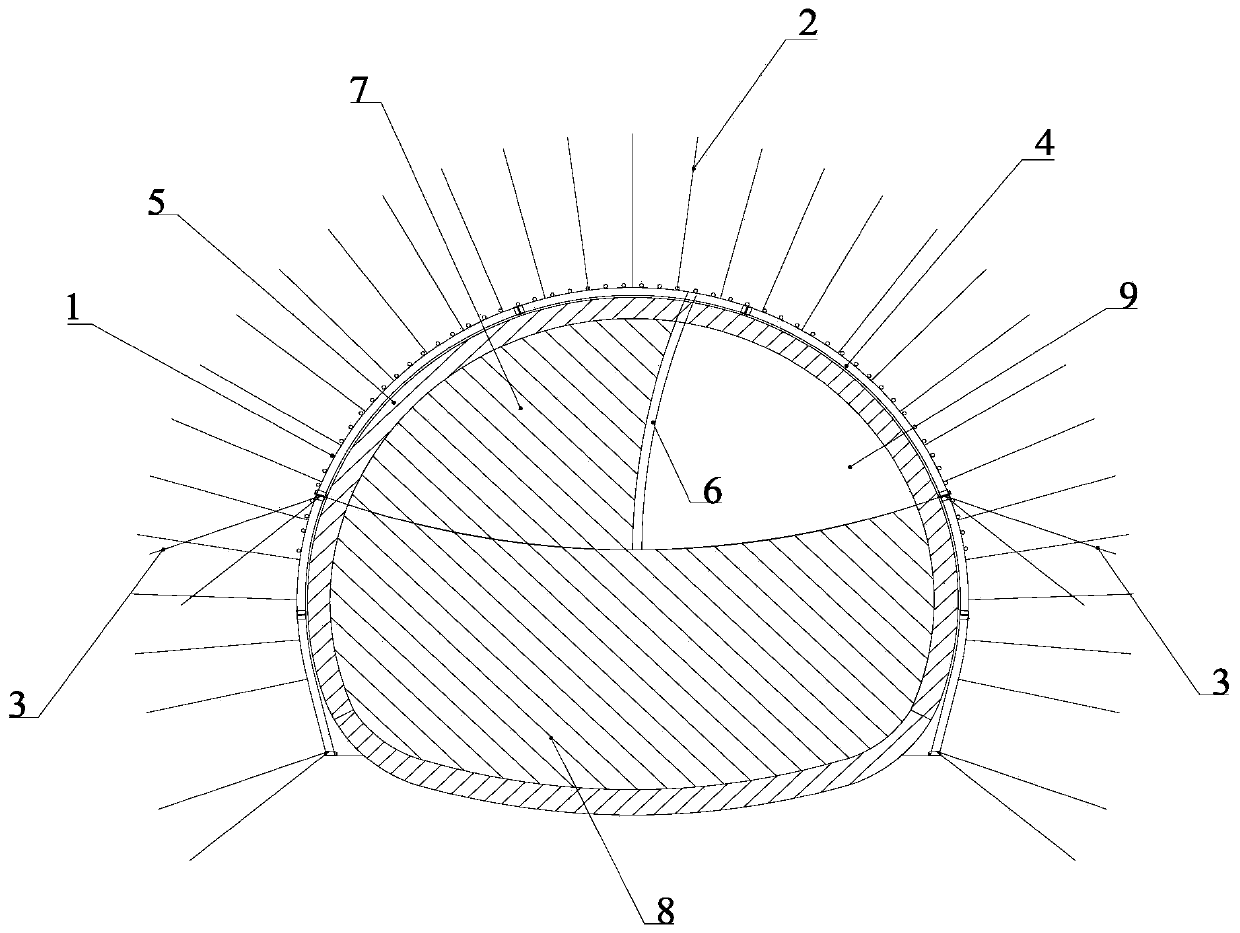

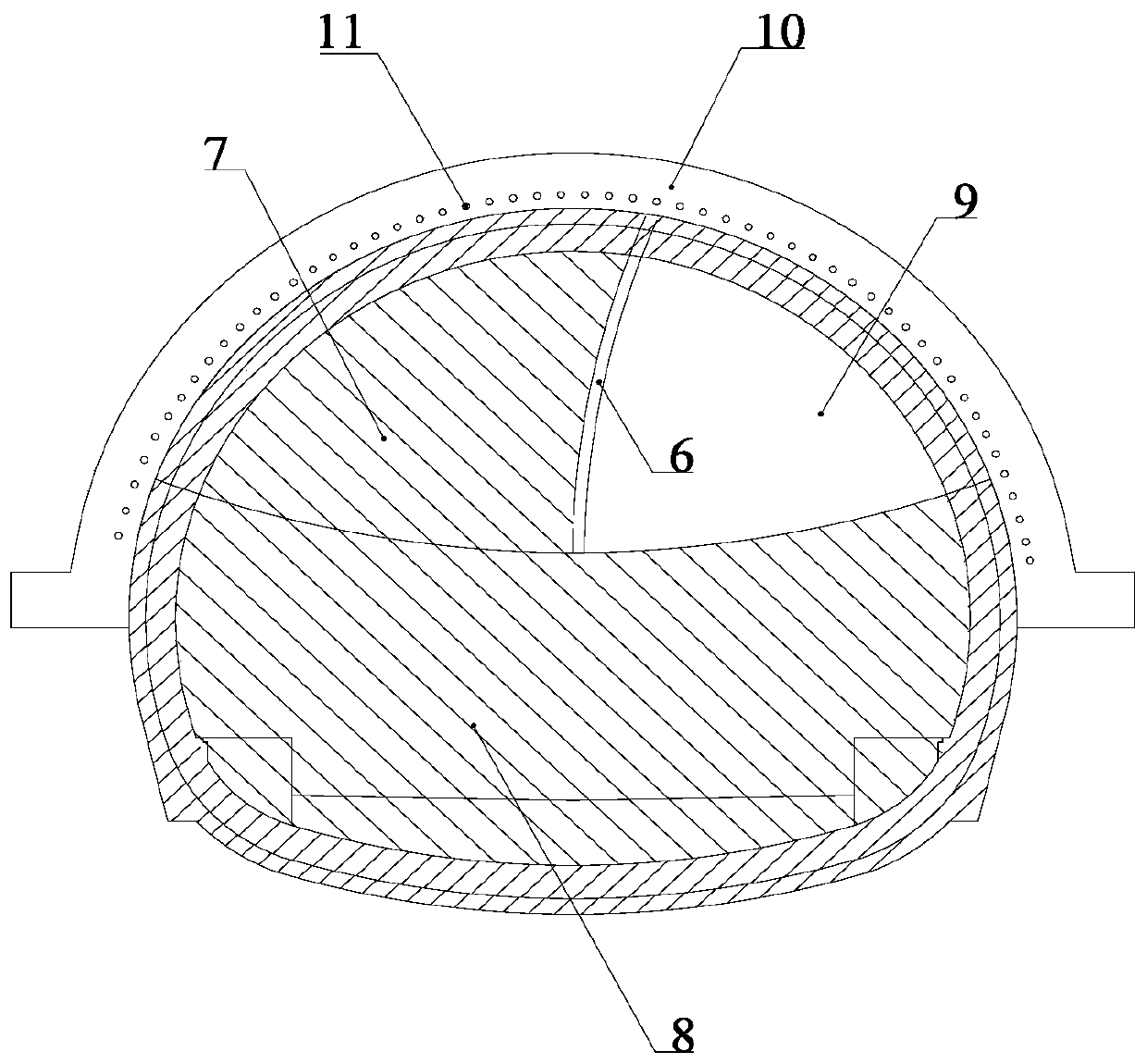

[0030] Such as Figure 1-Figure 3 As shown, a tunnel exit support structure includes an upper step 7 and a lower step 8 provided at the tunnel entrance, and a connecting slope 12 is connected between the upper step 7 and the lower step 8, and the connecting slope 12 The slope is less than or equal to 1 / 3, ensuring that the slope is gentle enough to facilitate the transportation organization of construction personnel and construction machinery.

[0031] One side of the upper step 7 is provided with a small guide hole 9, and also includes a temporary support 6 provided in time after the excavation of the small guide hole 9, and the temporary support 6 includes a steel frame shotcrete support ; and the advanced support 1, system anchor 2, lock foot anchor 3 and initial support 4 that are used to reinforce the surrounding rock of the tunnel around the tunnel entrance, the advanced support 1 includes an advanced small conduit, and the reinforcement The surrounding rock around the ...

Embodiment 2

[0034] Such as Figure 1-Figure 3 Shown, a kind of construction method of tunnel exit support structure, comprises the following steps:

[0035] Step 1: When the tunnel construction reaches the section adjacent to the entrance, adjust the construction method to the step method. The upper step 7 and the lower step 8 are connected by a connecting slope 12. The length of the upper and lower steps should be as long as possible, and the connection between the upper and lower steps should be ensured. The slope 12 is gentle enough to facilitate the transportation organization of construction personnel and construction machinery;

[0036] Step 2: Excavate the advanced small pilot tunnel 9 on the side of the upper step 7 of the tunnel. The small pilot tunnel 9 is excavated every cycle and then the advanced support 1, the system anchor 2, the locking foot anchor 3, and the initial support are applied. 4. Support measures such as secondary lining 5 and temporary support 6 ensure the saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com