Uncoupled continuous charge structure with eccentric retaining wall and its application method

A charging and eccentric technology, used in manufacturing tools, ceramic molding machines, blasting, etc., can solve problems such as increased blasting cost, detonating cord damage, excessive damage, etc., to improve energy utilization, save economic costs, overcome clamping effect for making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: In controlled blasting of peripheral holes,

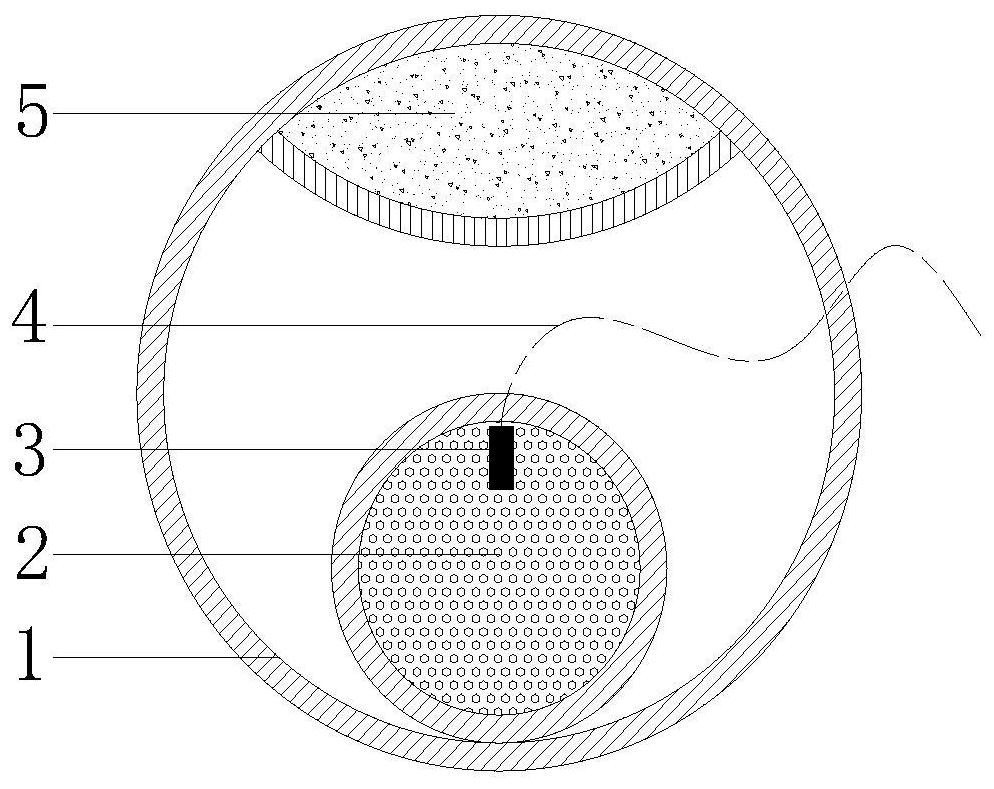

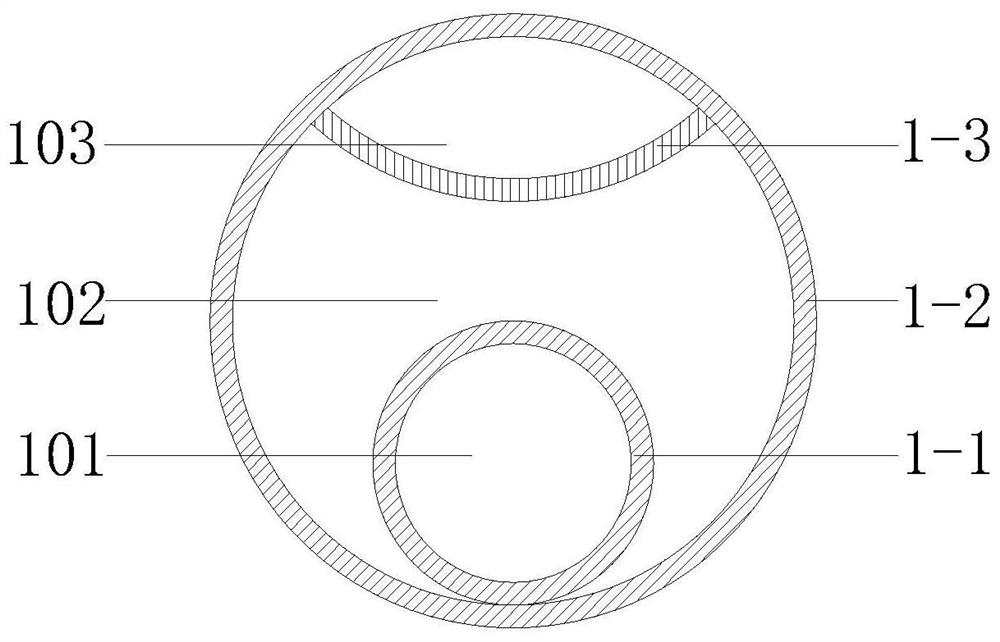

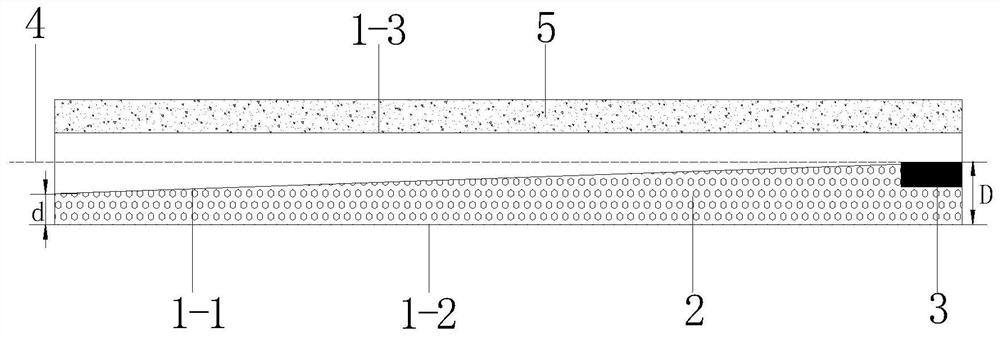

[0034] refer to Figure 1-4 , an eccentric retaining wall uncoupled continuous charging structure, comprising a PVC pipe 1, explosives 2, nonel detonator 3 and high wave impedance material 5, the PVC pipe 1 includes a charging pipe 1-1, a positioning pipe 1-2 and Arc partition 1-3, the charging tube 1-1 is located at the lower part of the inner cavity of the positioning tube 1-2, the upper part of the inner cavity of the positioning tube 1-2 is provided with an arc-shaped partition 1-3, and the charging tube 1-2 1 and arc-shaped partitions 1-3 are arranged along the axial direction of the PVC pipe 1 and the length is compatible with the PVC pipe 1. The internal space of the positioning pipe 1-2 is divided into a charge chamber 101, an air chamber 102 and a wall chamber from bottom to top. 103, the charge cavity 101 is filled with explosives 2, the explosives 2 are preferably No. 2 rock explosives, the bottom of t...

Embodiment 2

[0049] The non-coupling continuous charge structure of the eccentric retaining wall is the same as that of embodiment 1, and the different method steps are as follows:

[0050] The diameter of the charge tube increases from the orifice end to the bottom of the hole, and the diameter D at the bottom of the charge tube hole is proportional to the diameter d at the orifice end of the charge tube, D: d=1.3.

[0051] The explosive is emulsion explosive.

[0052] The components of high wave impedance concrete stones are Portland cement, iron sand, water and admixture, the Portland cement and the iron sand are mixed uniformly at a mass ratio of 1:5.0, and the water-cement mass ratio is 0.5, so The mass of the above-mentioned admixture is 4% of the mass of Portland cement. The admixture is composed of an accelerator and a hardening accelerator at a mass ratio of 1:1.5, and the mixture is evenly mixed to obtain high-wave impedance concrete, and then the high-wave impedance concrete is ...

Embodiment 3

[0054] The diameter of the charge tube increases from the orifice end to the bottom of the hole, and the diameter D at the bottom of the charge tube hole is proportional to the diameter d at the orifice end of the charge tube, D: d=1.2.

[0055] The explosive is a powdered explosive.

[0056] The components of the high wave impedance concrete stones are Portland cement, iron sand, water and admixtures, the Portland cement and the iron sand are uniformly mixed at a mass ratio of 1:3.0, and the water-cement mass ratio is 0.4 , the mass of the admixture is 4% of the mass of Portland cement, the admixture is formed by mixing the accelerator and the hardening agent at a mass ratio of 1:1.3, and the mixture is evenly mixed to obtain high-wave impedance concrete, and then the high-wave impedance concrete Pour it into the mold and take it out after 7 days of curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com