Grain size measuring method for equiaxial structure of two-phase titanium alloy

A technology of equiaxed structure and measurement method, which is applied in the field of determination of material microstructure structure, can solve the problem of no standard search for grain size, achieve the effects of compensating measurement errors, simplifying measurement, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The assay method of the present embodiment comprises the following steps:

[0027] Step 1. Select a magnification of 200× to prepare a metallographic photograph of the equiaxed structure of the two-phase titanium alloy, and then measure the percentage content Vvα=82% of the primary α grains in the equiaxed structure of the two-phase titanium alloy; the primary α grains Grains include spherical alpha grains;

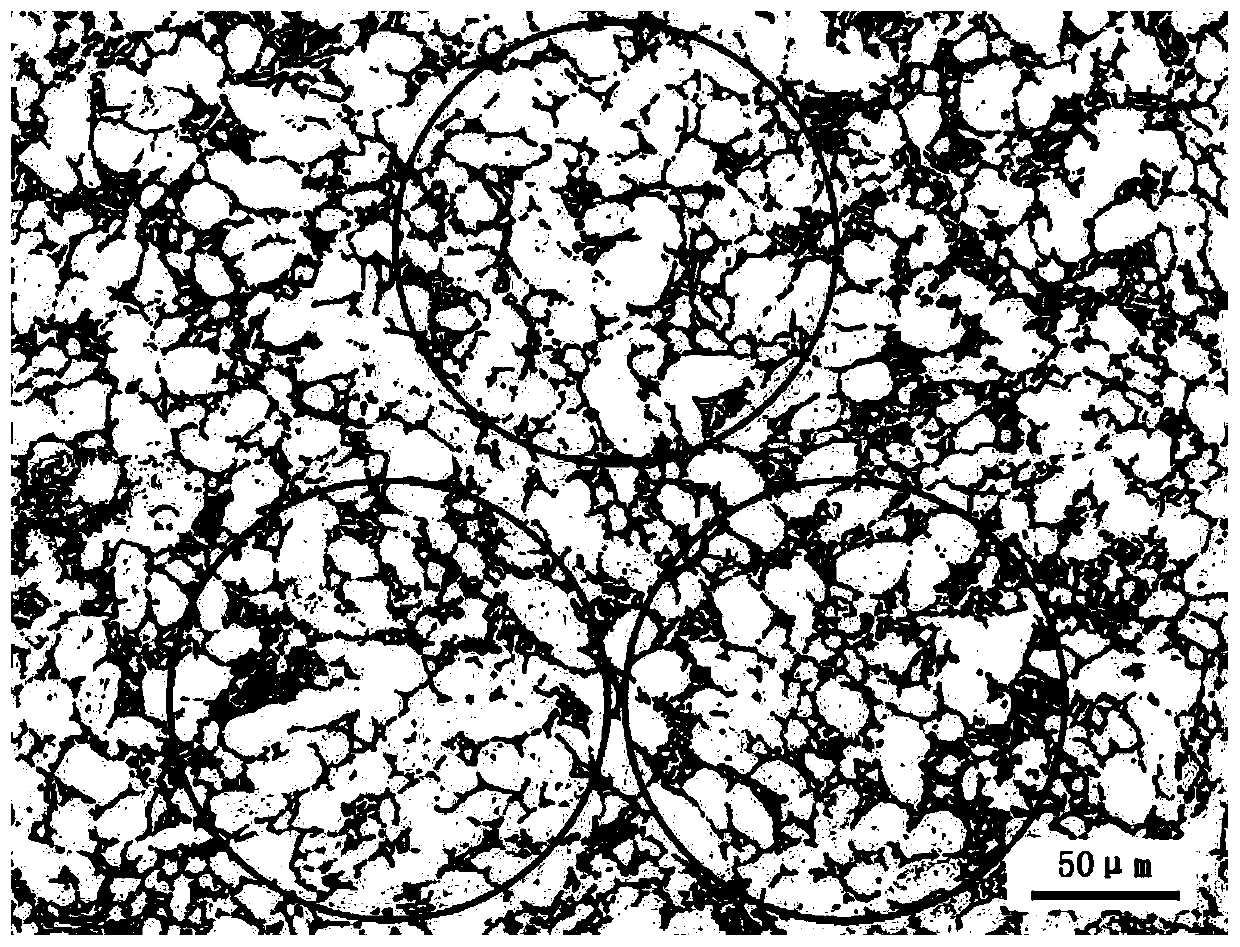

[0028] Step 2. Take the circle as the measurement line, and calculate the average intercept of the primary α grains by using the intercept point method The specific process of the intercept point method with the circle as the measuring line is: add three circles with a diameter of 30 mm on the metallographic photograph prepared in step 1, so that the number of the three circles and the primary α crystal grains is greater than 50 cutoff point, such as figure 1 As shown, and then count the number N of primary α grains intersecting and tangent to the three circles ...

Embodiment 2

[0034] The assay method of the present embodiment comprises the following steps:

[0035] Step 1. Select a magnification of 200× to prepare a metallographic photograph of the equiaxed structure of the two-phase titanium alloy, and then measure the percentage of primary α grains in the equiaxed structure of the two-phase titanium alloy Vvα=70%; the primary α crystals Grains include spherical α grains and long α grains;

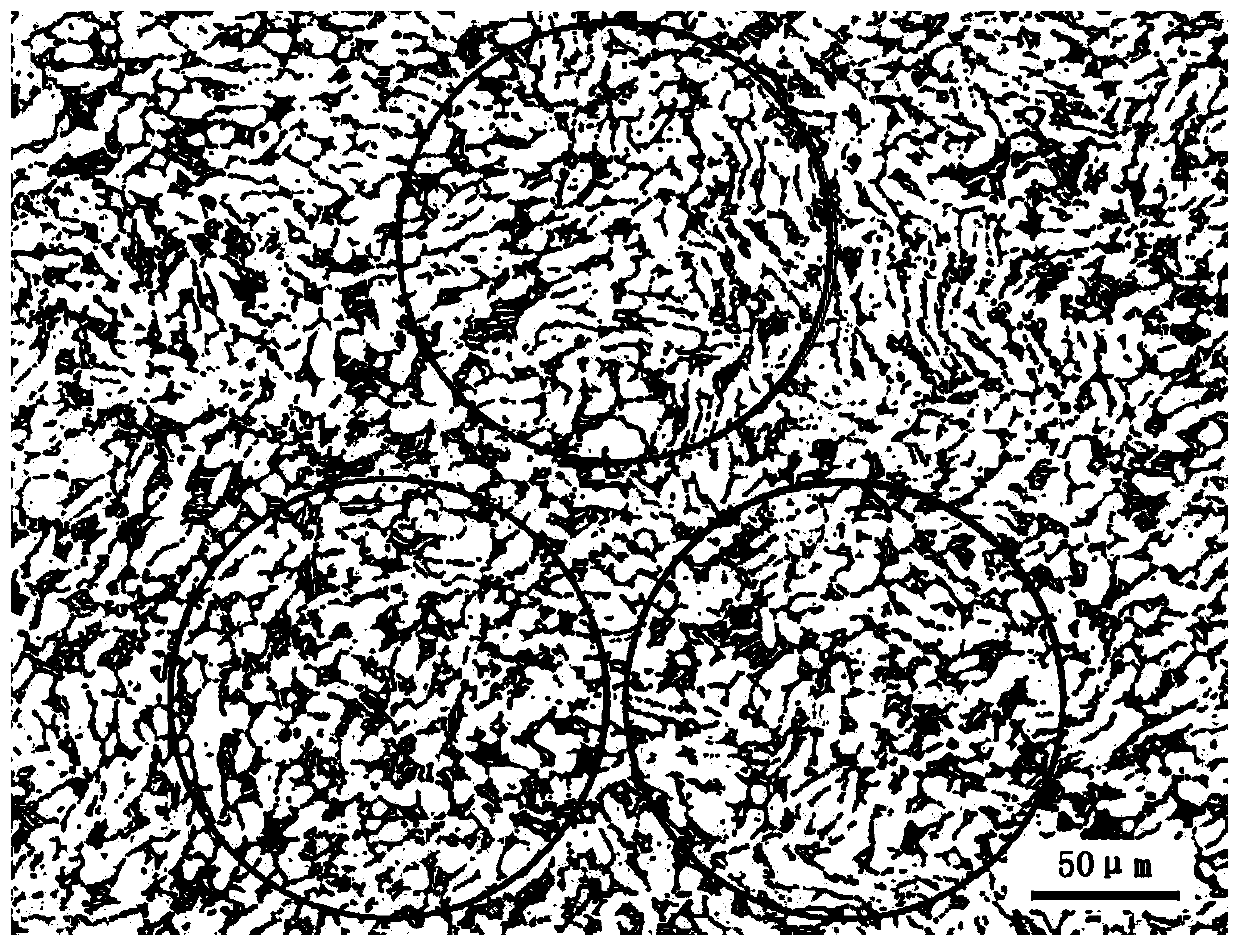

[0036] Step 2. Take the circle as the measurement line, and calculate the average intercept of the primary α grains by using the intercept point method The specific process of the intercept point method with the circle as the measuring line is: add three circles with a diameter of 30 mm on the metallographic photograph prepared in step 1, so that the number of the three circles and the primary α crystal grains is greater than 50 cutoff point, such as figure 2 As shown, and then count the number N of primary α grains intersecting and tangent to the three cir...

Embodiment 3

[0042] The assay method of the present embodiment comprises the following steps:

[0043] Step 1. Select a magnification of 500× to prepare a metallographic photograph of the equiaxed structure of the TC11 forging, and then measure the percentage of primary α grains in the equiaxed structure of the TC11 forging Vvα=45%; the primary α grains include spherical α grains and long α grains;

[0044] Step 2, take three straight lines with different directions as the measurement lines, and calculate the average intercept l of the primary α grains by the intercept method; the specific process of the intercept method with the three straight lines as the measurement lines is: in step one Three straight lines with different directions are added to the prepared metallographic photo, with lengths of 117 μm, 166 μm, and 118 μm, respectively, so that the three straight lines have more than 50 intercept points with the primary α grains, as shown in image 3 Shown, and then count the number N o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com