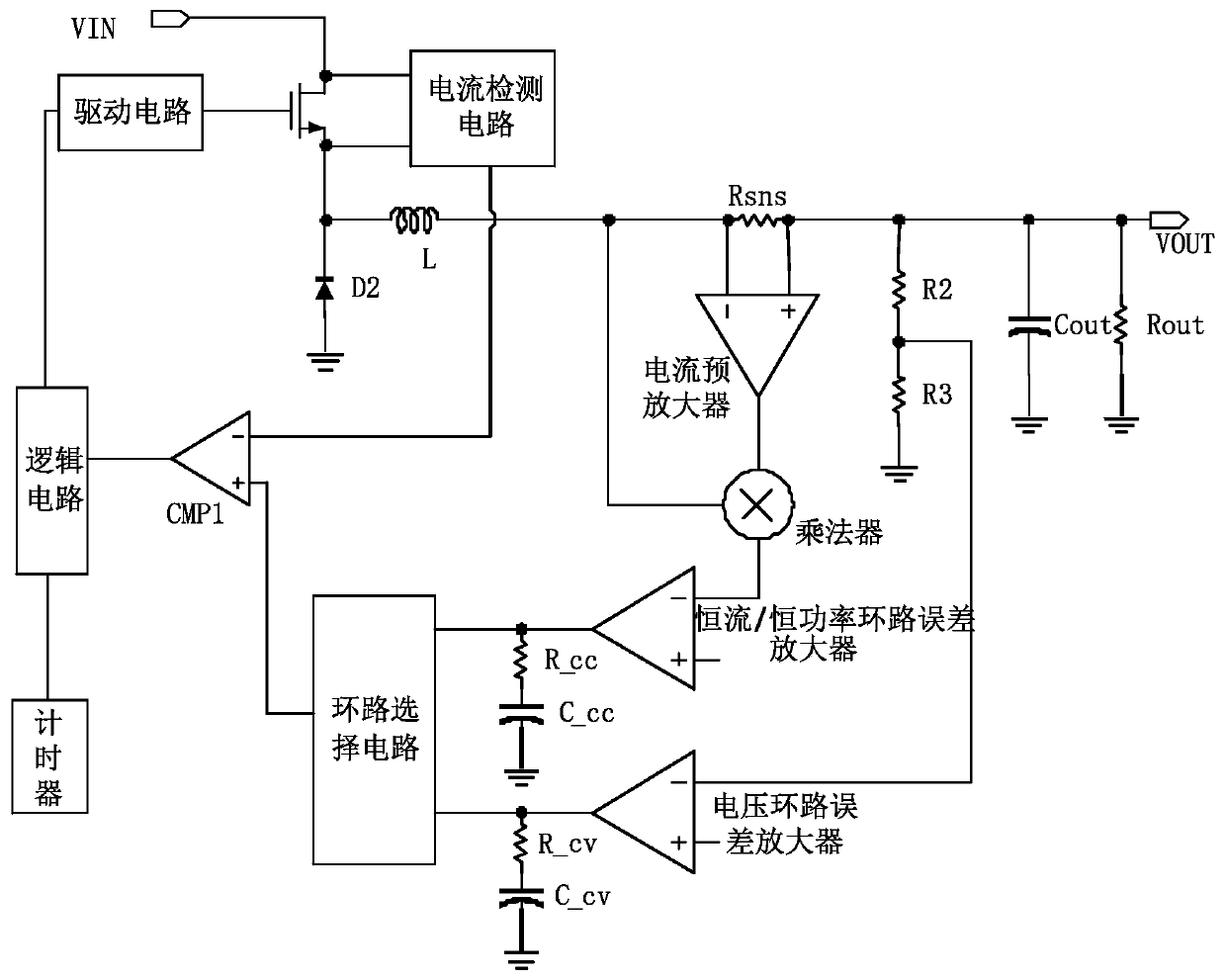

Constant-current constant-power control circuit for DC-DC converter and implementation method

A constant power control and circuit technology, applied in the direction of converting DC power input to DC power output, control/regulation systems, output power conversion devices, etc., can solve the problems of large power loss, high cost, complex structure, etc. Small loss, constant power, and solving the effect of complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

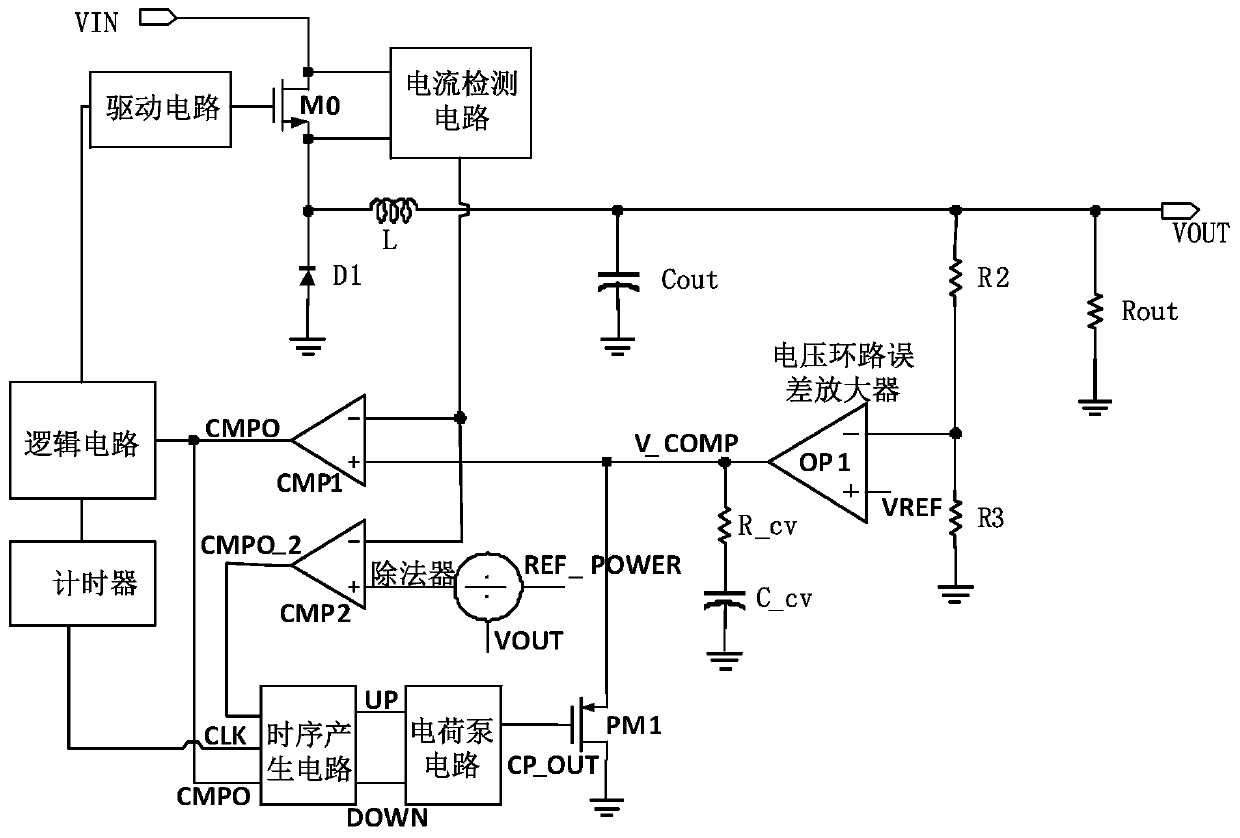

[0028] Such as figure 2 As shown, the present invention discloses a constant current and constant power control circuit for DC-DC, including a timer, a voltage loop error amplifier OP1, a current detection circuit, a comparator CMP1, and a comparator CMP2, and a timing generation circuit , a charge pump circuit, a MOS tube PM1, a divider, the divider is connected to the non-inverting input of the comparator CMP2, the inverting input of the comparator CMP2 is connected to the current detection circuit, and the CMPO of the timing generation circuit The interface is connected to the output terminal of the comparator CMP1, the CMPO_2 interface is connected to the output terminal of the comparator CMP2, the CLK interface is connected to the output terminal of the timer, the Up interface is connected to the UP interface of the charge pump circuit, and the Down interface is connected to the DOWN of the charge pump circuit Interface connection, the gate of the MOS transistor PM1 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com