Method for suppressing mechanical resonance of cutting machine servo system

A mechanical resonance and servo system technology, applied in control systems, vector control systems, motor generator control, etc., can solve problems such as complex algorithm design, high hardware support, and large amount of computation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] combine Figure 1~6 The present invention is further described:

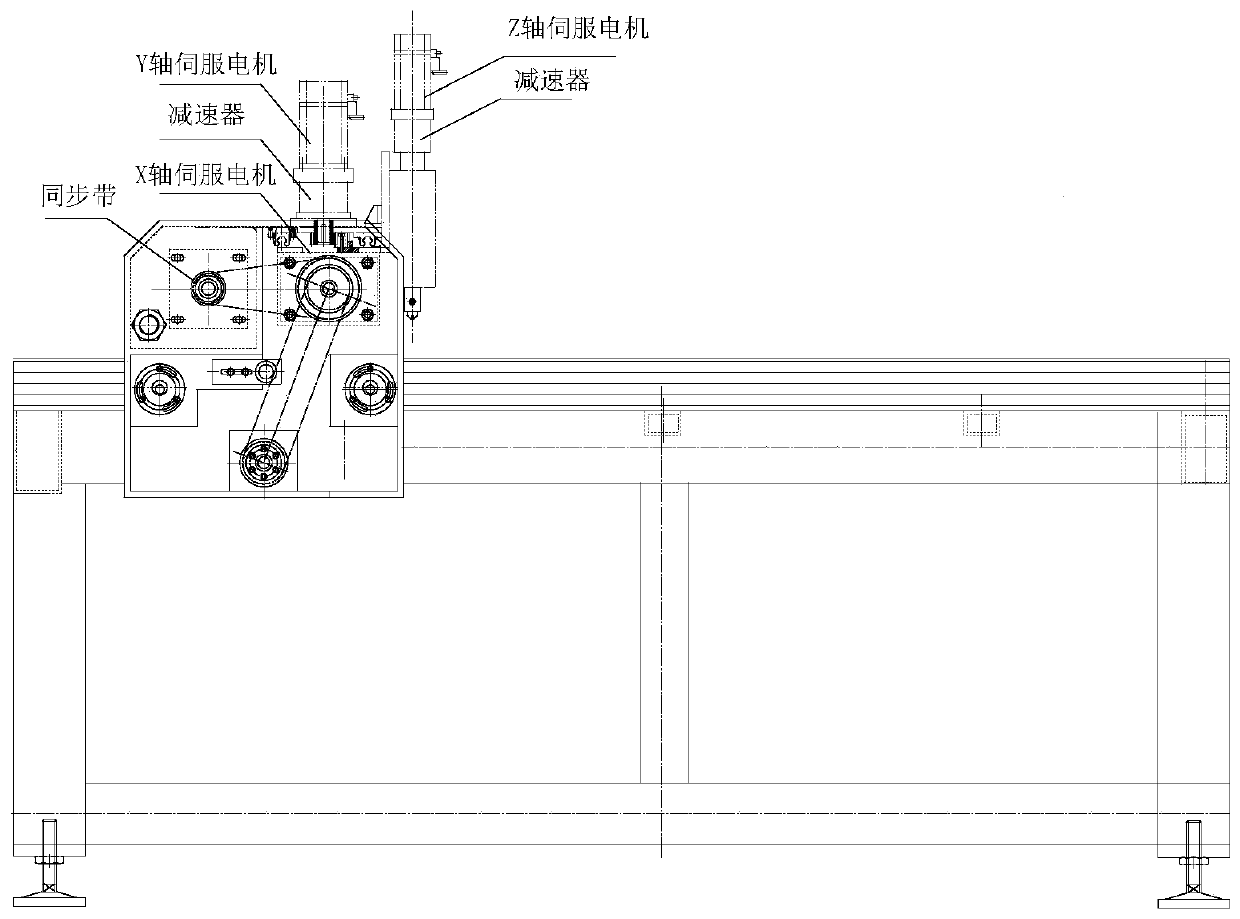

[0056] attached figure 1 It is a schematic diagram of the mechanical structure of the glass cutting machine. In the deep processing of glass, the high precision and high performance of the glass cutting machine are important guarantees for the subsequent glass processing and the quality of the finished product. The glass cutting machine system is mainly composed of a frame, a conveying system, a positioning system, Road cutting system consists of four parts. The cutter path cutting system is a motion mechanism, which consists of a three-axis servo system: the X-axis servo motor drives the beam to move through the synchronous belt mechanism, the Y-axis servo motor drives the cutting knife box through the reducer, and the Z-axis servo motor drives the cutter wheel through the reducer sports. In the glass cutting process, the control system is required to have good dynamic characteristics to meet high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com