Processing method of cured fish, film coating agent for cured fish and application of film coating agent

A processing method and technology of coating agent, which are applied in the direction of preserving meat/fish by coating a protective layer, etc., can solve the problems such as excessive oxidation of protein and fat, unfavorable quality and flavor of cured fish, and reduction of product value, and reduce fat. and protein oxidation, improving quality and safety, good emulsification and antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

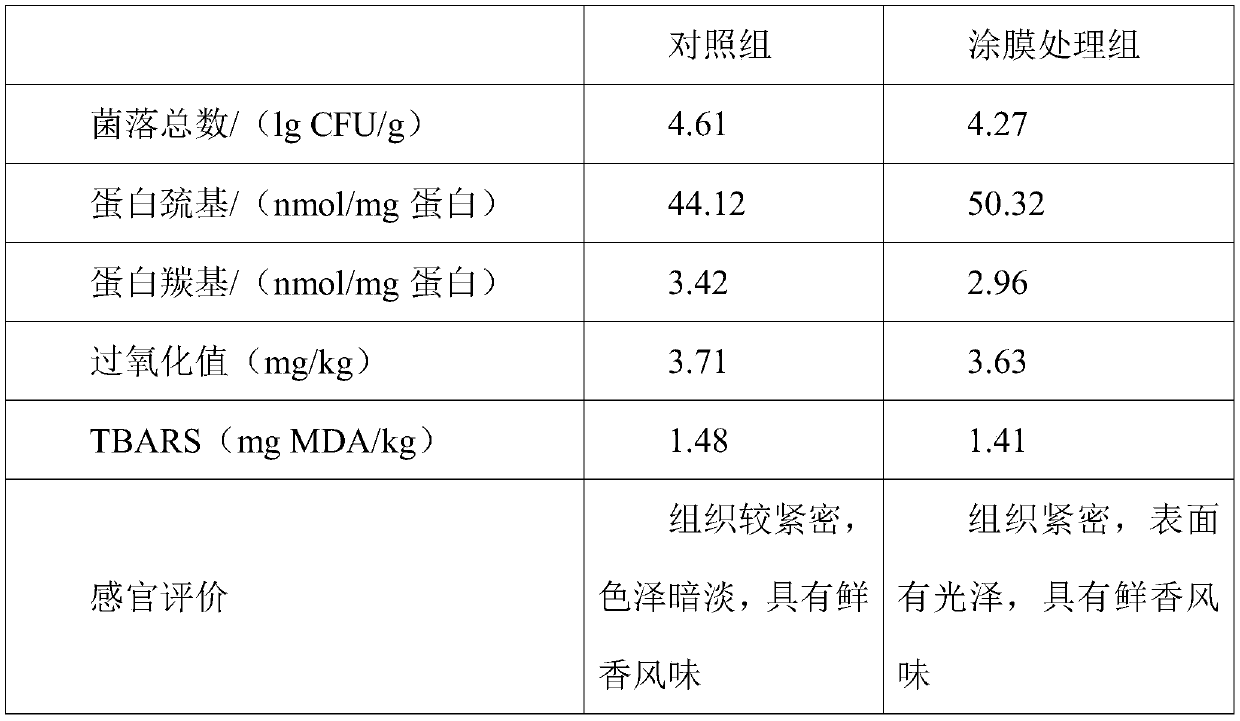

Embodiment 1

[0030] A processing method for cured fish, comprising the following steps:

[0031] (1) After washing, draining and weighing the fresh grass carp samples, evenly apply salt (10% salt content) on the surface of the fish samples, stack them neatly in the basin, compact them with objects, and marinate at 10°C Cook for 7 days, turn over the fish pieces every 12 hours, and cut the grass carp into 3×4×1.5cm evenly sized fish pieces after marinating.

[0032] (2) Wheat gluten, glycerin, mangosteen chitin extract and water are mixed, wherein the ratio of each component is: 5% wheat gluten, 1% glycerin, 0.2% mangosteen chitin extract , and the rest is water. When mixing, stir magnetically for 20 minutes, place in a water bath at 60°C for 20 minutes, cool to room temperature, and vacuum degas for 5 minutes to obtain a salted fish coating agent, wherein,

[0033] Air-dry and crush the mangosteen shells, add appropriate amount of water, and extract polysaccharides with the aid of ultraso...

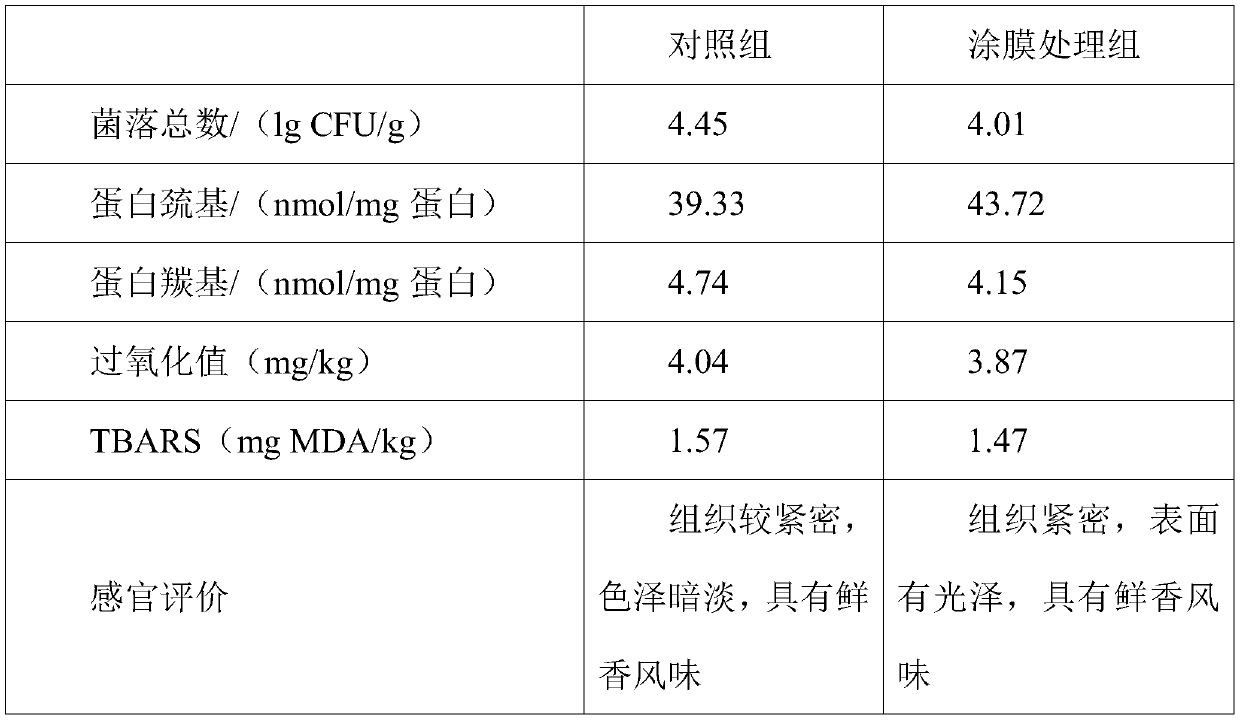

Embodiment 2

[0041] A processing method for cured fish, comprising the following steps:

[0042] (1) After washing, draining and weighing the fresh grass carp samples, evenly apply salt (10% salt content) on the surface of the fish samples, stack them neatly in the basin, compact them with objects, and marinate at 10°C Cook for 7 days, turn over the fish pieces every 12 hours, and cut the grass carp into 3×4×1.5cm evenly sized fish pieces after marinating.

[0043] (2) Wheat gluten, glycerin, mangosteen chitin extract and water are mixed, wherein the ratio of each component is: 5% wheat gluten, 1% glycerin, 0.4% mangosteen chitin extract , and the rest is water. When mixing, stir magnetically for 20 minutes, place in a water bath at 60°C for 20 minutes, cool to room temperature, and vacuum degas for 5 minutes to obtain the composite coating solution of wheat gluten-mangosteen chitosan extract, in which the mangosteen shells are air-dried , pulverize, add appropriate amount of water, and e...

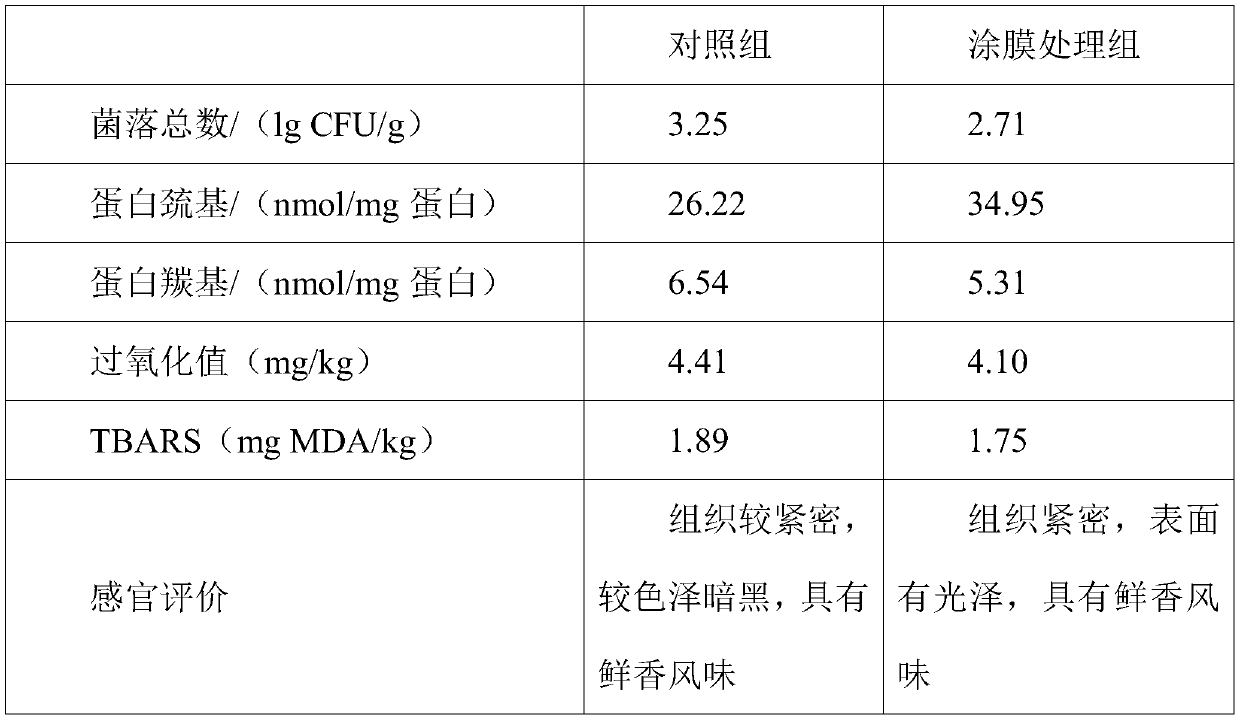

Embodiment 3

[0051] A processing method for cured fish, comprising the following steps:

[0052] (1) After washing, draining and weighing the fresh grass carp samples, evenly apply salt (10% salt content) on the surface of the fish samples, stack them neatly in the basin, compact them with objects, and marinate at 10°C Cook for 7 days, turn over the fish pieces every 12 hours, and cut the grass carp into 3×4×1.5cm evenly sized fish pieces after marinating.

[0053] (2) Wheat gluten, glycerin, mangosteen chitin extract and water are mixed, wherein the ratio of each component is: 5% wheat gluten, 1% glycerin, 0.8% mangosteen chitin extract , and the rest is water. When mixing, stir magnetically for 20 minutes, place in a water bath at 60° C. for 20 minutes, cool to room temperature, and vacuum degas for 5 minutes to obtain the composite coating solution of wheat gluten-mangosteen chitosan extract, air-dry the mangosteen shell, Crush, add appropriate amount of water, and extract polysacchari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com