Laser processing apparatus and method, laser packaging method, laser annealing method

A laser processing and laser technology, which is applied in the fields of laser annealing, laser packaging method, and laser processing device, can solve the problems of increasing yield, not reaching the optimum effect, and increasing cost, so as to improve yield, reduce cost, and improve efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

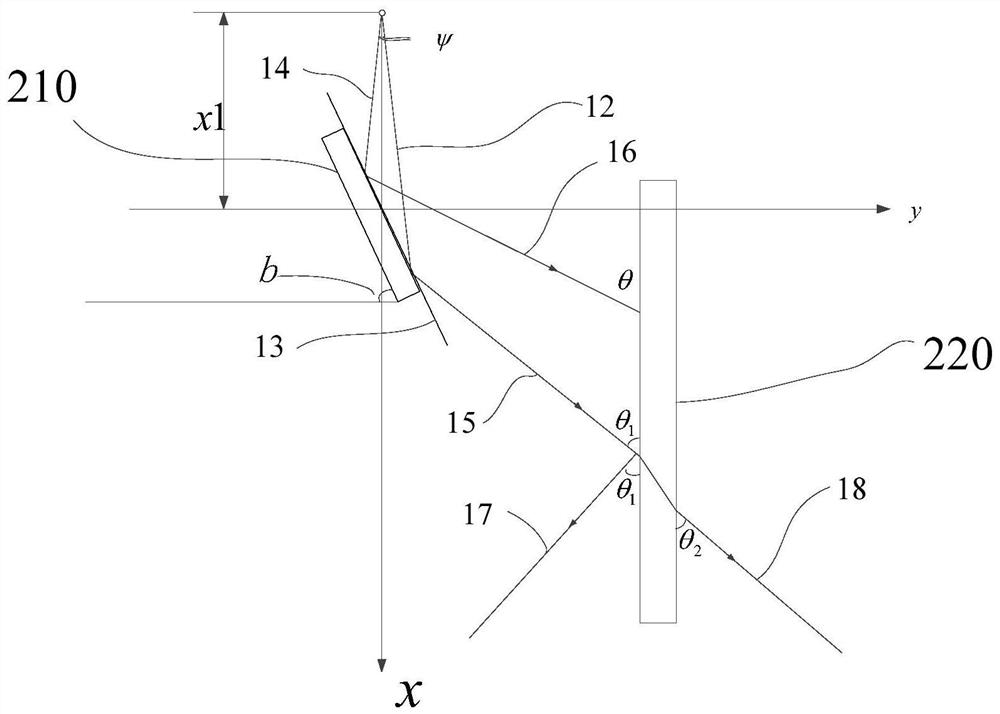

[0076] The difference between this embodiment and Embodiment 1 is that please refer to Figure 8 , in order to achieve no dead angle in the scanning process, two reflectors can be arranged on both sides of the beam splitter 220, which are respectively the second reflector 230 and the third reflector 240 on the left side, the second reflector 230 and the third reflector 240 The beam splitter 220 is symmetrical, and the height of the two reflecting mirrors relative to the material to be processed is smaller than the height of the beam splitter 220 relative to the material to be processed.

[0077] The reflected light and refracted light split by the beam splitter 220 are respectively reflected by the second reflector 230 and the third reflector 240 into the lens module. At this time, the beam splitter 220 and the two reflectors are all perpendicular to the lens module. The processing rate and processing path of refracted light are the same.

[0078] Please refer to Figure 9 a...

Embodiment 3

[0080] The difference between this embodiment and the first embodiment is that please refer to Figure 14 and Figure 15 :

[0081] Please refer to Figure 11 , at this time, it is also necessary to set two reflectors, and the two reflectors are also placed vertically, but the heights of the two reflectors relative to the material to be processed are not equal. In addition, the beam splitter 220 is placed obliquely, and the angle between it and the horizontal plane is α.

[0082] Figure 11 In the laser beam incident to the beam splitter 220, two edge rays with the largest spacing are selected, which are respectively 21 and 22, and when they are incident on the beam splitter 220, two incident points are generated, which are point A and point B respectively, and are projected to point A The light above is reflected by the beam splitter 220 to form a reflected light 23, and the light projected on point B is reflected by the beam splitter 220 to form a reflected light 24, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com