Silicon-based OLED product

A silicon-based and product technology, applied in the field of silicon-based OLED products, can solve the problems of small size and high cost, and achieve the effect of reducing the area and realizing the narrow frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

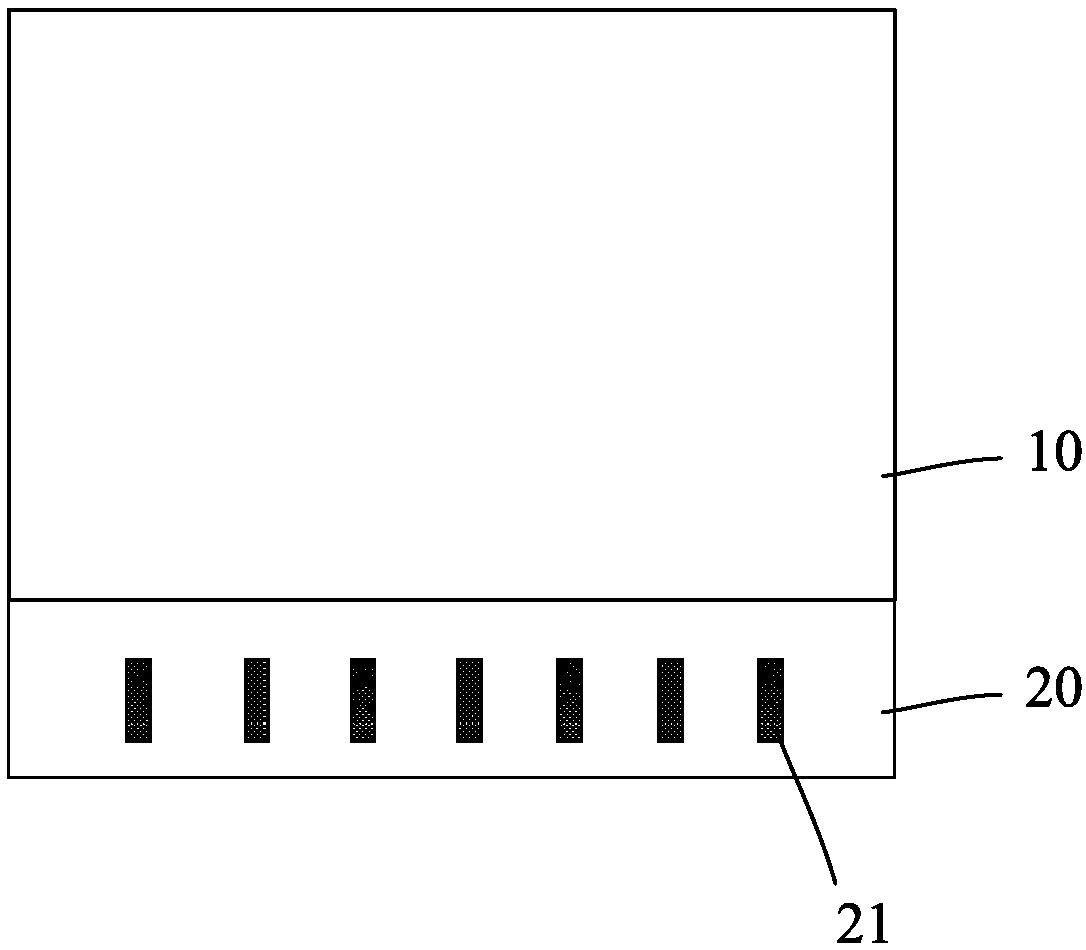

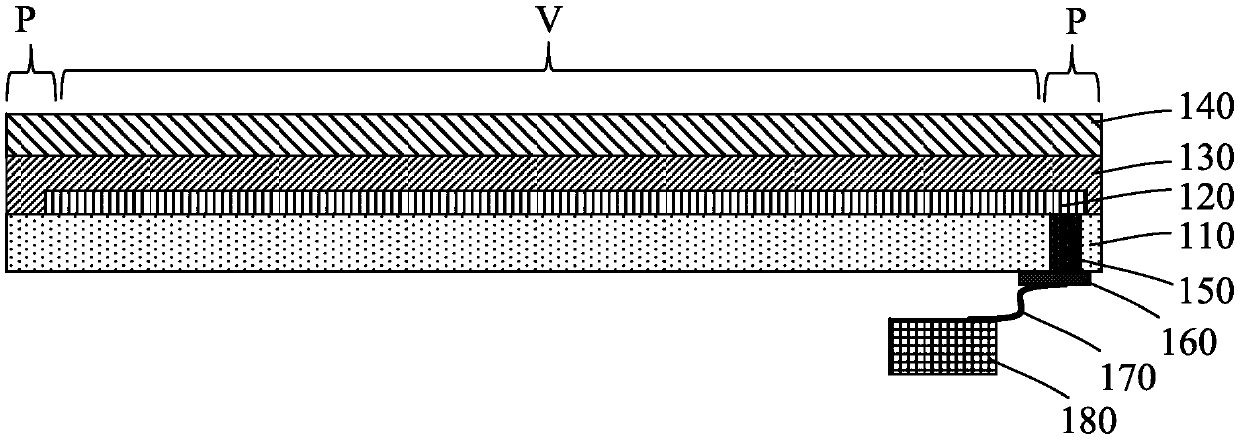

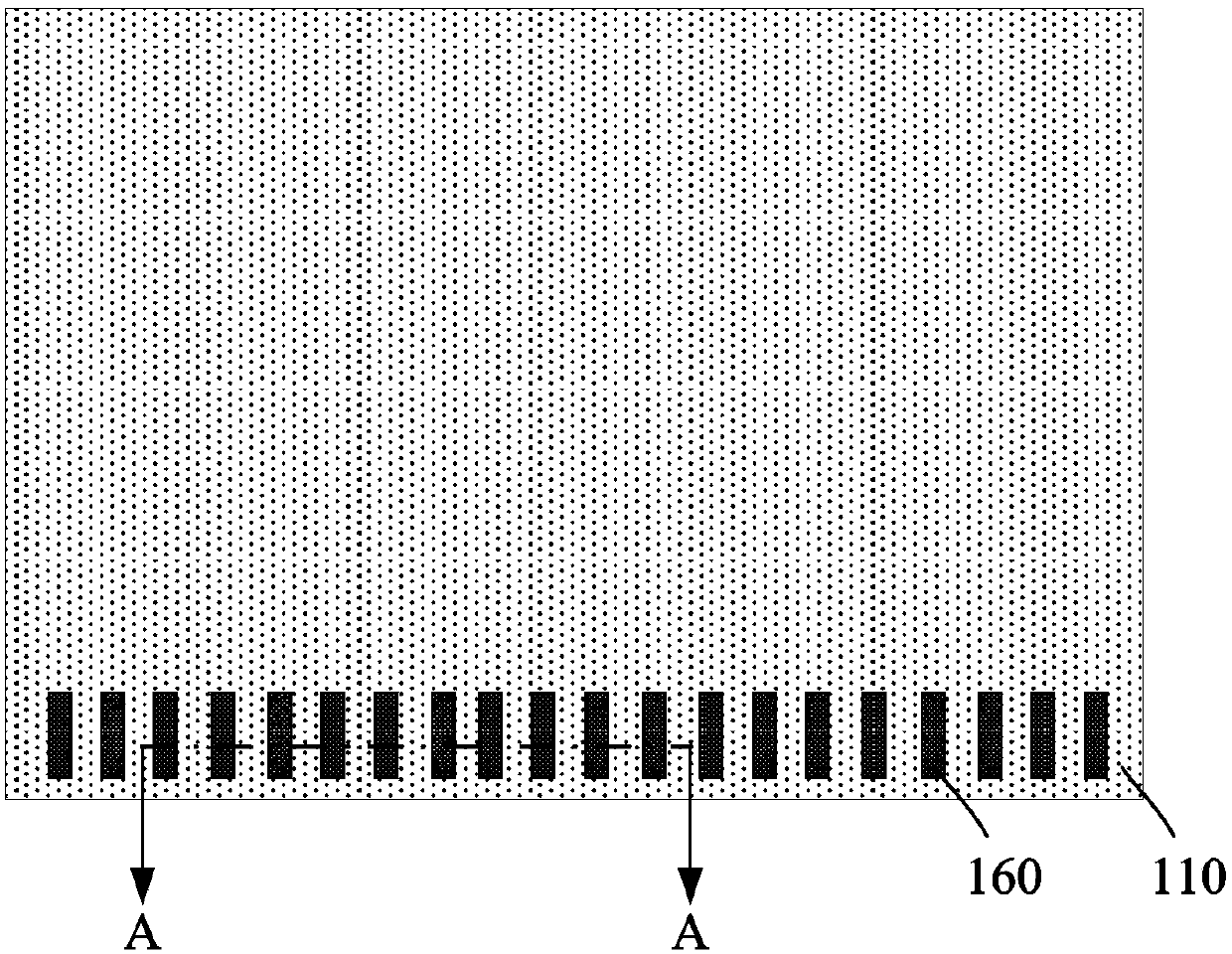

[0024] In silicon-based OLED products, when the chips originally produced outside are integrated into the silicon-based OLED display panel, that is, when the corresponding integrated circuits are integrated in the silicon-based OLED display panel, the corresponding cost will be very high, and it will also occupy Large product area.

[0025] Therefore, one way to reduce the cost is to use externally bonded chips instead of making corresponding integrated circuits in the display panel.

[0026] However, when the corresponding integrated circuit is not produced in the display panel, but chooses to bind external chips, due to the high resolution of the corresponding product, there are too many source signal lines, which leads to too many bonding pads for the chip The problem. Due to the limited size of the silicon-based OLED display panel, it is impossible to manufacture a large number of bonding pads to the edge area of the display panel, so the bonding pads have to be placed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com