Polymer devolatilization device

A devolatilization device, polymer technology, applied in vertical tube evaporators, evaporator accessories, evaporation, etc., can solve the problems of reduced polymer yield, high volatile vapor velocity, vapor phase pipeline blockage, etc., and achieve short heating time. , The effect of reducing entrainment and preventing scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

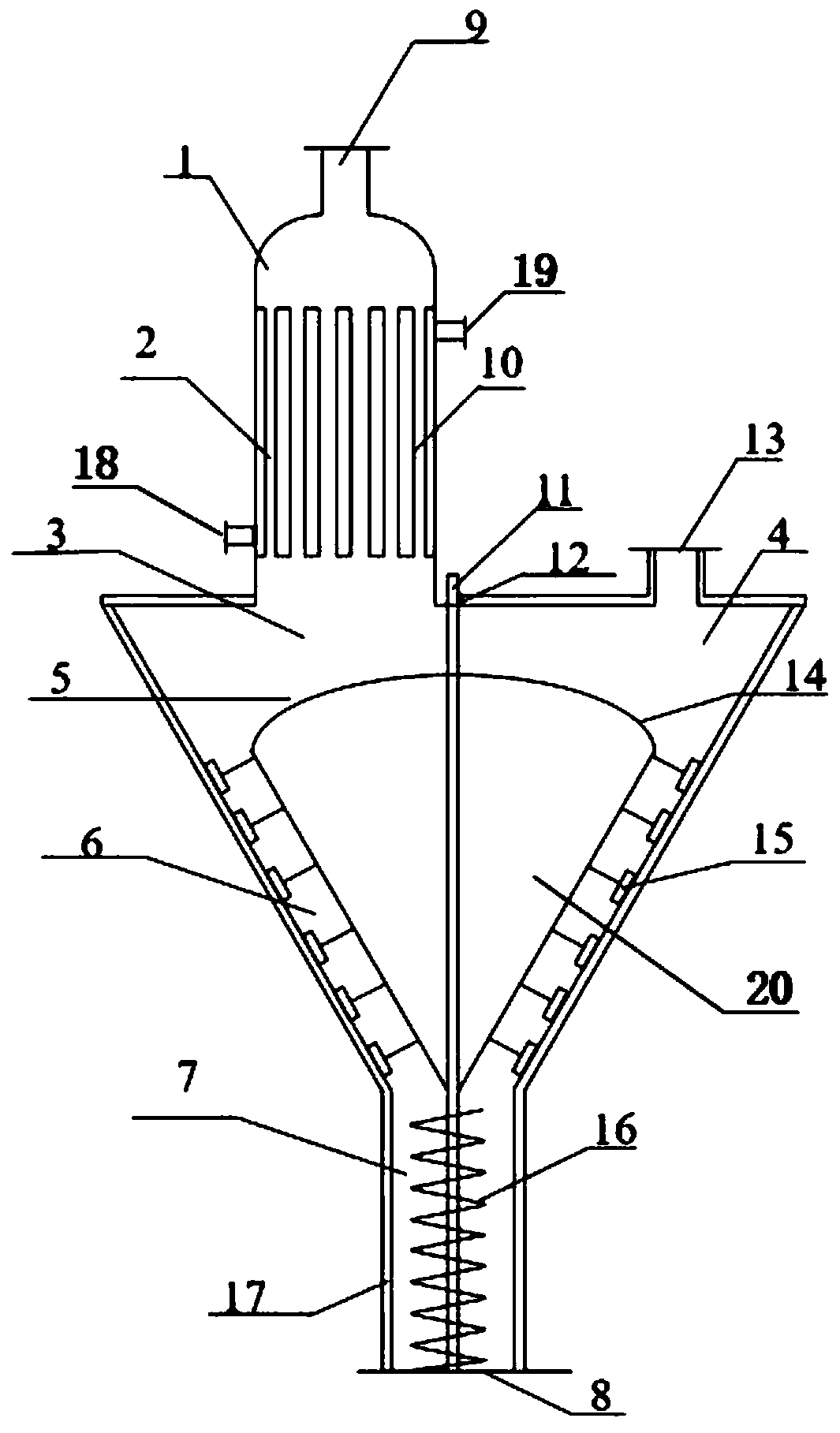

[0035] See attached figure 1 , is a structural schematic diagram of a polymer devolatilization device in an embodiment of the present invention, and the devolatilization device is provided with: a feed distribution area 1, a heating devolatilization area 2, a strip devolatilization area 3, and a vapor phase collection and discharge area 4 , Falling film devolatilization zone 5, bubble breaking devolatilization zone 6 and material collection zone 7.

[0036] The feed distribution area 1 is provided with a feed inlet 9, and the feed inlet 9 is arranged on the top or side of the feed distribution area 1, and the polymer enters the devolatilization from the feed inlet 9. device. In this embodiment, the feed inlet 9 is arranged at the top of the feed distribution area 1 .

[0037] The heating devolatilization zone 2 is located below the feed distribution zone 1, and the heating devolatilization zone 2 is provided with a heating device, which is used to heat the polymer to the tem...

Embodiment 2

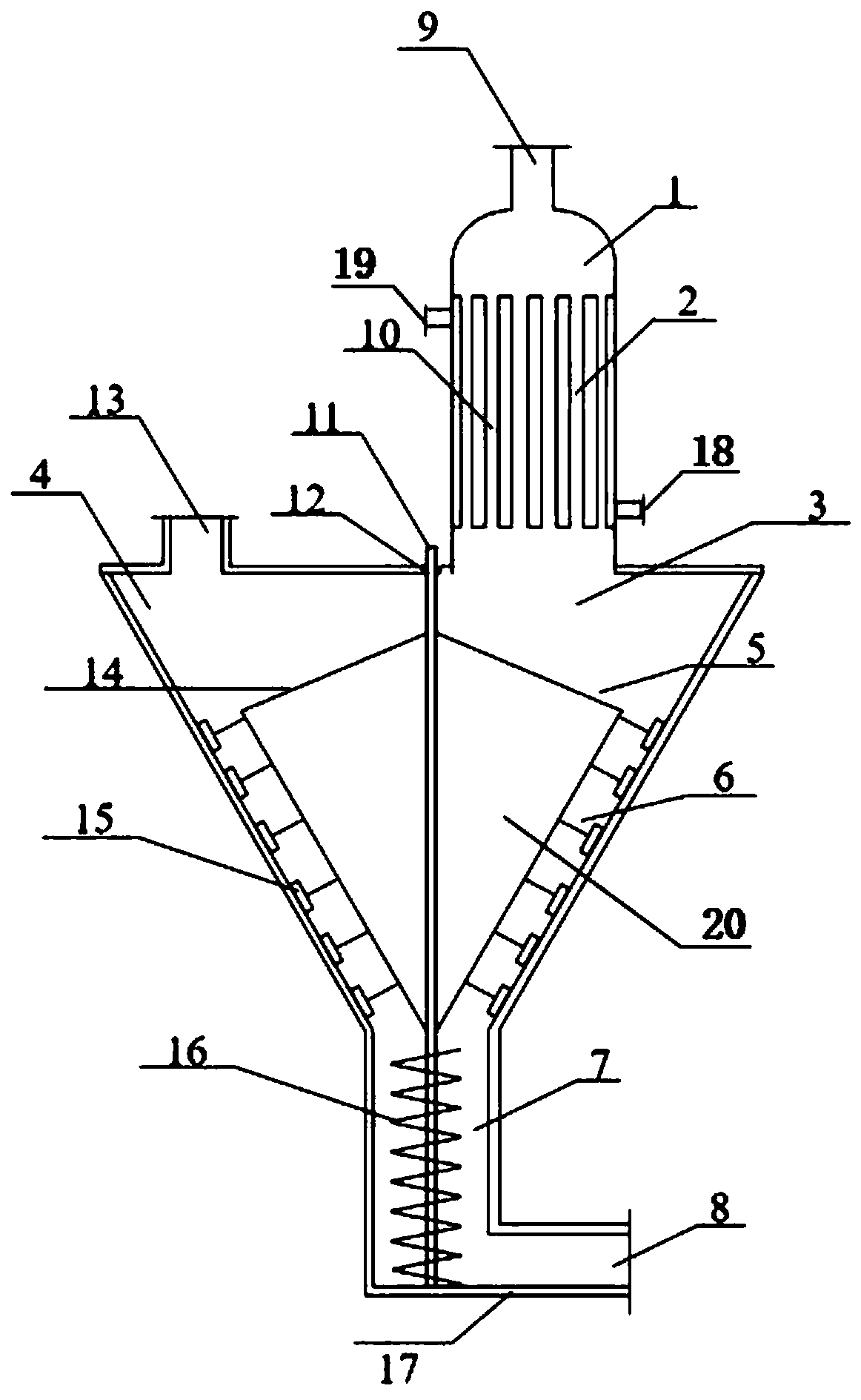

[0045] See attached figure 2, is a structural schematic diagram of a polymer devolatilization device in another embodiment of the present invention, and the devolatilization device is provided with: a feed distribution area 1, a heating devolatilization area 2, a strip devolatilization area 3, and a vapor phase collection and discharge area 4. Falling film devolatilization zone 5, bubble breaking devolatilization zone 6 and material collection zone 7.

[0046] The feed distribution area 1 is provided with a feed inlet 9, and the feed inlet 9 is arranged on the top or side of the feed distribution area 1, and the polymer enters the devolatilization from the feed inlet 9. device. In this embodiment, the feed inlet 9 is arranged at the top of the feed distribution area 1 .

[0047] The heating devolatilization zone 2 is located below the feed distribution zone 1, and the heating devolatilization zone 2 is provided with a shell-and-tube heat exchanger, and the tube layer of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com