Flue gas emission system and desulfurization device of power plant

A flue gas emission and power plant technology, applied to the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of water vapor entry, waste of water resources, white feathers at the chimney outlet, etc., to reduce temperature and humidity, and reduce water pollution. Consumption, reduce the effect of project cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

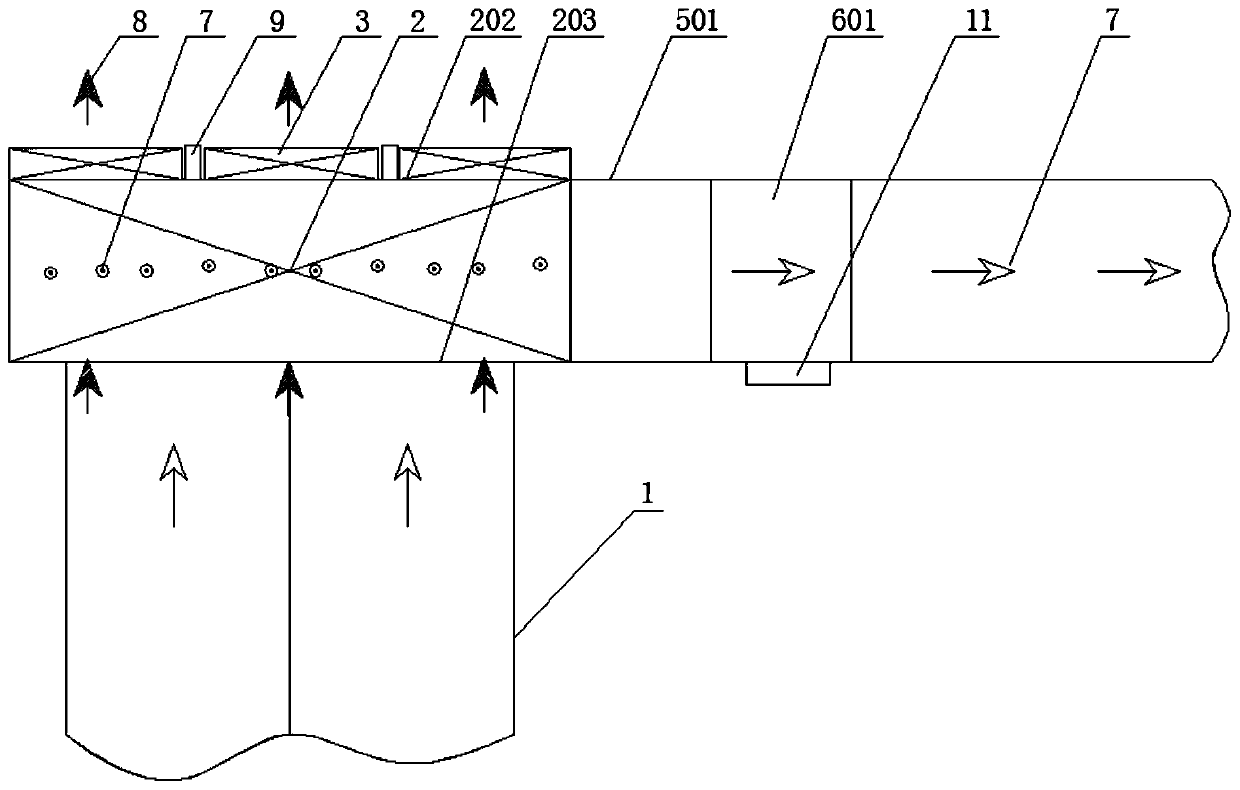

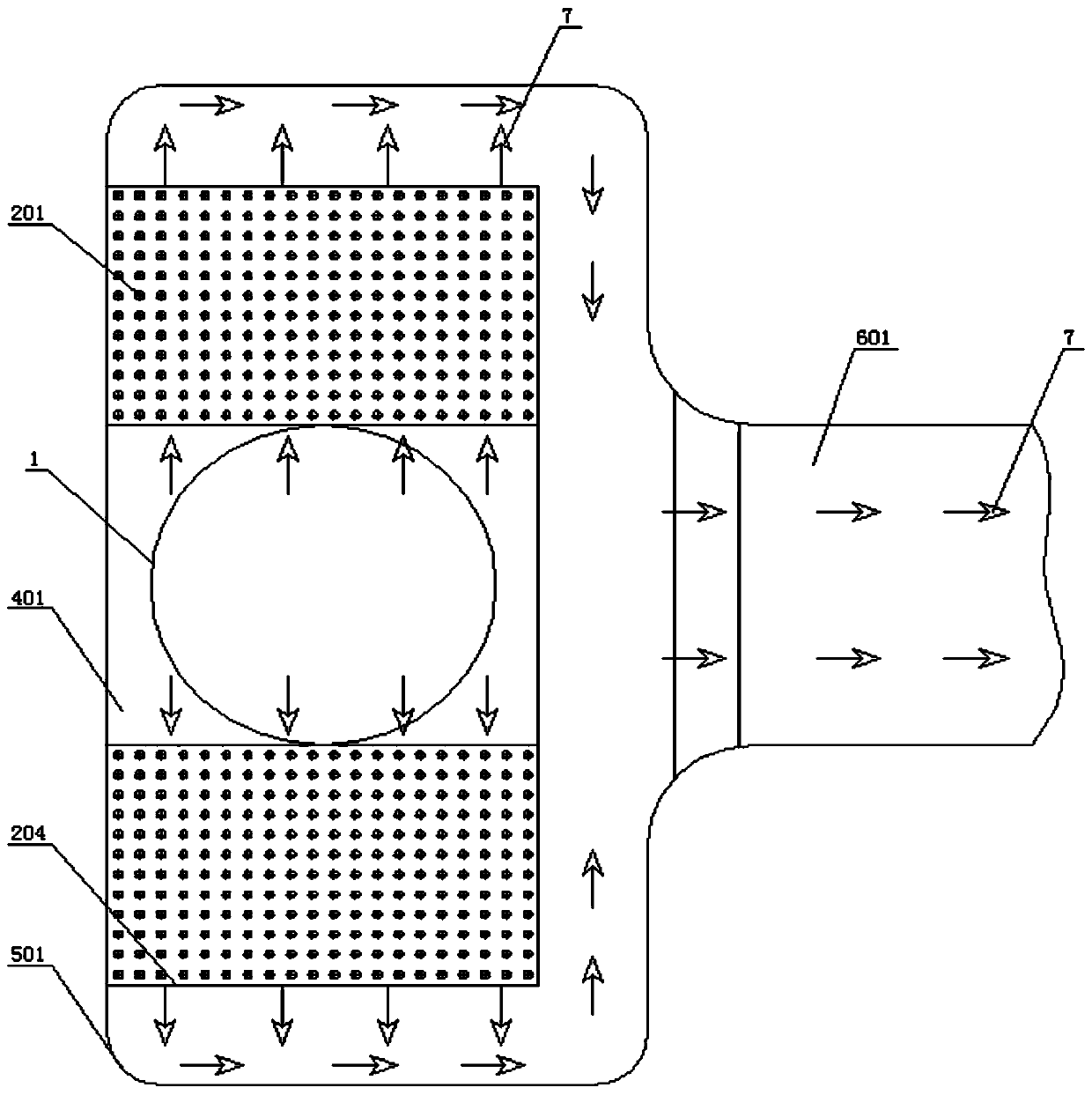

[0035] A power plant flue gas exhaust system, such as figure 1 with figure 2 As shown, including the desulfurization tower 1, the top of the desulfurization tower 1 is provided with a tubular heat exchanger 2, and the tubular heat exchanger 2 is directly connected to the desulfurization tower 1 through the air intake air box to introduce the desulfurized wet and clean flue gas, which will be lower than the wet flue gas. The ambient air of the clean flue gas is introduced into the heat exchange tube 201 of the tubular heat exchanger 2 as a cold medium, and the wet and clean flue gas desulfurized by the desulfurization tower 1 is heat-exchanged and condensed, and the clean flue gas after heat exchange enters the belt The exhaust channel of the liquid collection tank 11, the liquid collection tank 11 is arranged at the low point of the exhaust channel.

[0036] In this embodiment, a water spray or spray system is installed at the inlet of the cooling medium of the tubular heat ...

Embodiment 2

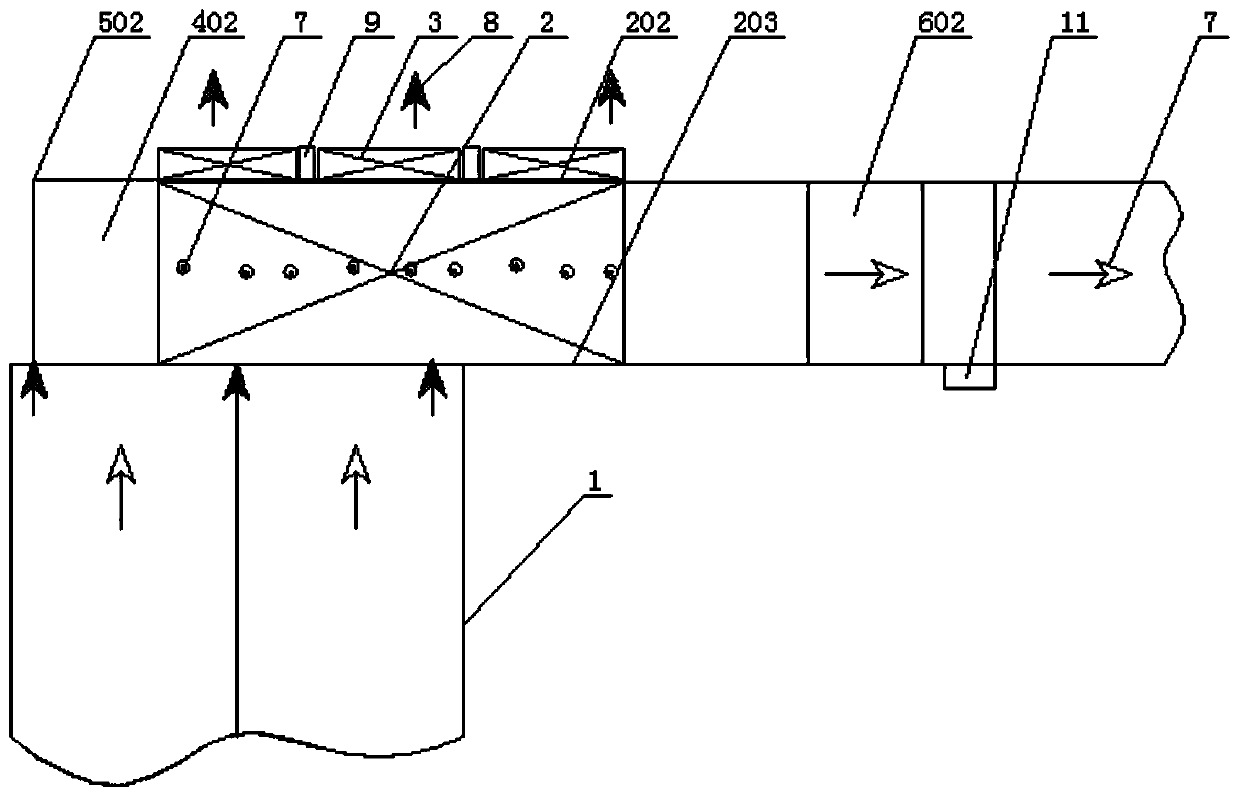

[0049] A power plant flue gas exhaust system, such as image 3 with Figure 4 As shown, including the desulfurization tower 1, the top of the desulfurization tower 1 is provided with a tubular heat exchanger 2, and the tubular heat exchanger 2 is directly connected to the desulfurization tower 1 through the air intake air box to introduce the desulfurized wet and clean flue gas, which will be lower than the wet flue gas. The ambient air of the clean flue gas is introduced into the heat exchange tube 201 of the tubular heat exchanger 2 as a cold medium, and the wet and clean flue gas desulfurized by the desulfurization tower 1 is heat-exchanged and condensed, and the clean flue gas after heat exchange enters the belt The exhaust channel of the liquid collection tank 11, the liquid collection tank 11 is arranged at the low point of the exhaust channel.

[0050] In this embodiment, a water spray or spray system is installed at the inlet of the cooling medium of the tubular heat ...

Embodiment 3

[0062] A power plant flue gas exhaust system, such as Figure 5 with Image 6 As shown, including the desulfurization tower 1, the top of the desulfurization tower 1 is provided with a tubular heat exchanger 2, and the tubular heat exchanger 2 is directly connected to the desulfurization tower 1 through the air intake air box to introduce the desulfurized wet and clean flue gas, which will be lower than the wet flue gas. The ambient air of the clean flue gas is introduced into the heat exchange tube 201 of the tubular heat exchanger 2 as a cold medium, and the wet and clean flue gas desulfurized by the desulfurization tower 1 is heat-exchanged and condensed, and the clean flue gas after heat exchange enters the belt The exhaust channel of the liquid collection tank 11, the liquid collection tank 11 is arranged at the low point of the exhaust channel.

[0063] In this embodiment, a water spray or spray system is installed at the inlet of the cooling medium of the tubular heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com