Catalyst composite support, catalyst based on catalyst composite support and preparation method of catalyst

A technology of catalyst carrier and composite carrier, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problem of poor performance and the influence of ozone catalytic oxidation nbsCOD catalyst on catalytic performance and other problems, to achieve the effect of reducing the amount of ozone, excellent carrier performance, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

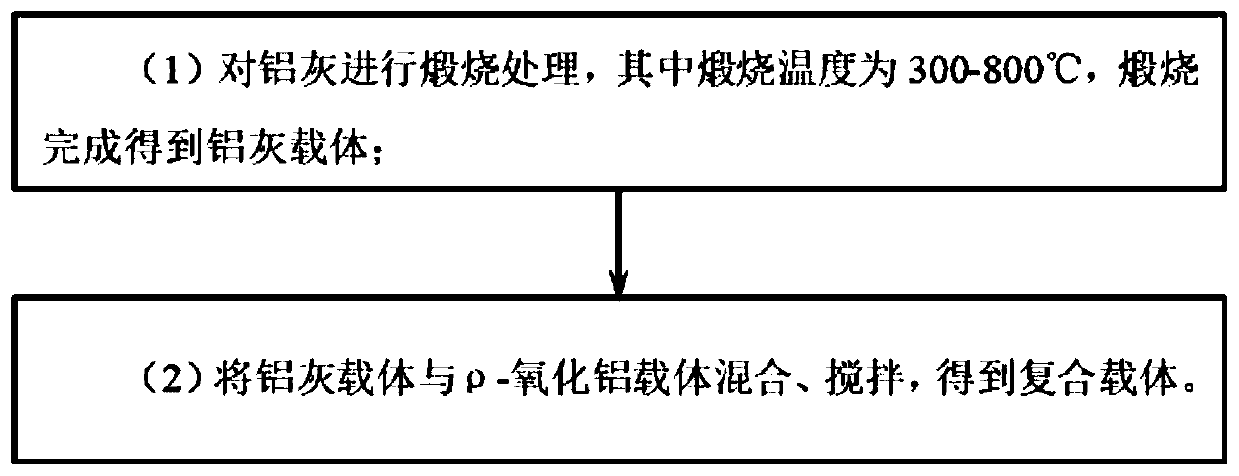

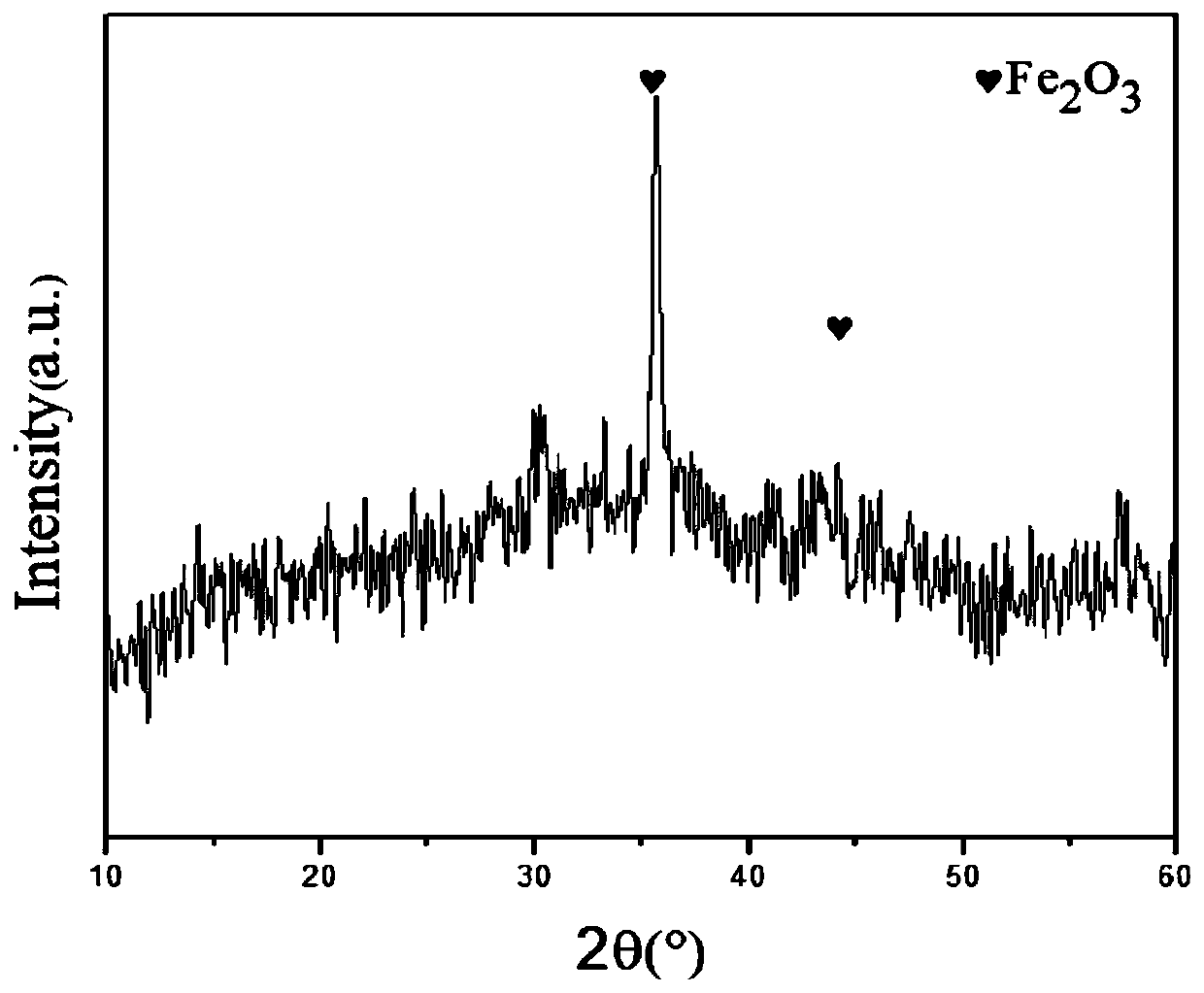

[0049] The preparation method of the catalyst of the ozone catalytic oxidation nbsCOD based on composite support of the present invention, concrete steps are as follows:

[0050] S100, the carrier and the active ingredient are mixed and finely ground

[0051] The active components of the catalyst and the catalyst carrier are mixed and finely ground by using a ball milling tank, the rotating speed of the ball milling tank is 200-500r / min, and the ball milling time is 2-6h, so that a uniform dispersion system can be obtained efficiently; the catalyst carrier is the above-mentioned Composite carrier for supporting catalyst; after ball milling, a mixed fine material dispersion system is obtained, and the particle size of the mixed fine material obtained by mixing and fine grinding is ≤300 mesh, which makes the catalyst have a larger specific surface, which is conducive to improving catalytic activity and catalytic efficiency. It is worth noting that the mixed material is dried to ...

Embodiment 1

[0064] A kind of composite carrier for supporting catalyst of the present embodiment, comprises aluminum ash carrier and rho-alumina carrier, and the doping mass ratio of aluminum ash carrier and rho-alumina is 1:4; Wherein aluminum ash carrier is made of aluminum The ash is obtained by calcining, and the calcining temperature of the aluminum ash is 300-800°C.

[0065] The preparation method of a kind of composite carrier for loading catalyst of the present embodiment is as follows

[0066] (1) Calcining the aluminum ash, wherein the calcination temperature is 400° C., and the aluminum ash carrier is obtained after the calcination is completed;

[0067] (2) Mix and stir the aluminum ash carrier and the ρ-alumina carrier, and the doping mass ratio of the aluminum ash carrier and ρ-alumina carrier is 1:4 to obtain a composite carrier.

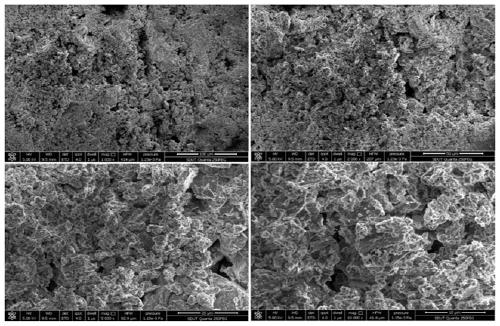

[0068] The aluminum ash carrier of this example and the rho-alumina carrier are jointly prepared to obtain a composite carrier with a large spe...

Embodiment 2

[0078] A kind of composite carrier for supporting catalyst of the present embodiment, comprises aluminum ash carrier and rho-alumina carrier, and the doping mass ratio of aluminum ash carrier and rho-alumina is 1:1; Wherein aluminum ash carrier is made of aluminum The aluminum ash is calcined at a temperature of 500 °C.

[0079] The preparation method of a kind of composite carrier for loading catalyst of the present embodiment is as follows

[0080] (1) Calcining the aluminum ash, wherein the calcination temperature is 500° C., and the aluminum ash carrier is obtained after the calcination is completed;

[0081] (2) Mix and stir the aluminum ash carrier and the ρ-alumina carrier, and the doping mass ratio of the aluminum ash carrier and ρ-alumina carrier is 1:1 to obtain a composite carrier.

[0082] The aluminum ash carrier of this example and the rho-alumina carrier are jointly prepared to obtain a composite carrier with a larger specific surface area, which provides more ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com