Preparation method of modified copper-based catalyst for furfural hydrogenation to furfuryl alcohol

A copper-based catalyst, a technology for preparing furfuryl alcohol, applied in chemical instruments and methods, physical/chemical process catalysts, organic chemistry, etc., can solve problems such as no copper-based catalyst, and achieve good hydrogenation effect, simple operation and good catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Accurately weigh 0.2g MgCO 3 , 1g of anhydrous formic acid and 20mL of 1,4-dioxane were added to a 50mL autoclave, sealed, and stirred at 170°C for 30min. After cooling, add 1g Cu(NO 3 ) 2 4H 2 O, sealed reactor, N 2 Replace 3 to 5 times to empty, and react at 170°C for 30 minutes. After cooling, centrifuge, wash, and dry under vacuum at 60°C to obtain 57% Cu-MgCO 3 Composite catalyst. In a similar manner, change the additive to CaCO 3 、BaCO 3 or Ba(CH 3 COO) 2 ·H 2 O, copper salt precursor is Cu(HCOO) 2 4H 2 O, Cu(CH 3 COO) 2 ·H 2 O or CuSO 4 ·5H 2 O, modified Cu-based catalysts supported by different metals or additives can be prepared.

[0025] The above Cu-MgCO 3 Add 0.3g of catalyst, 0.6g of furfural and 20mL of 1,4-dioxane into the reaction kettle, then add 1.15g of anhydrous formic acid, after mixing and sealing, use N 2 The air was replaced 3 to 5 times, and the reaction was carried out at 170° C. for 2 hours. The conversion rate of furfuryl ...

Embodiment 2

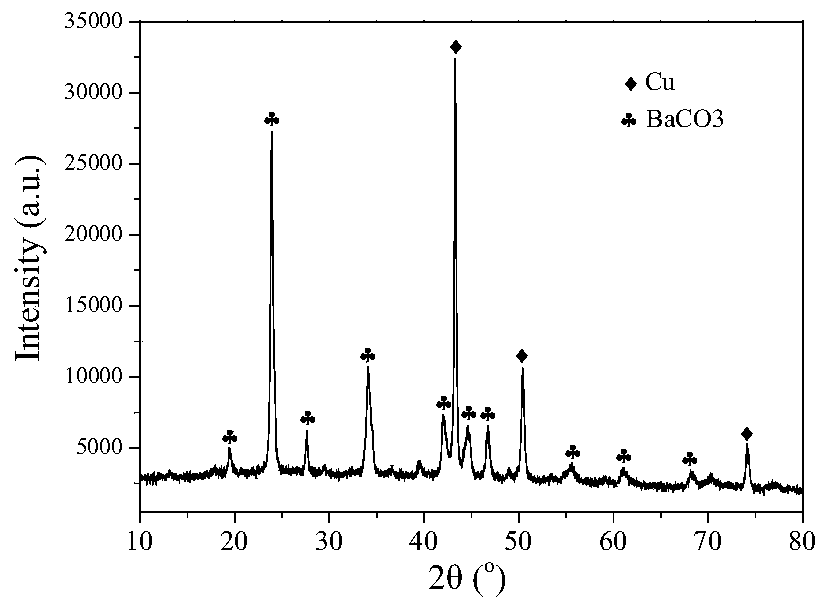

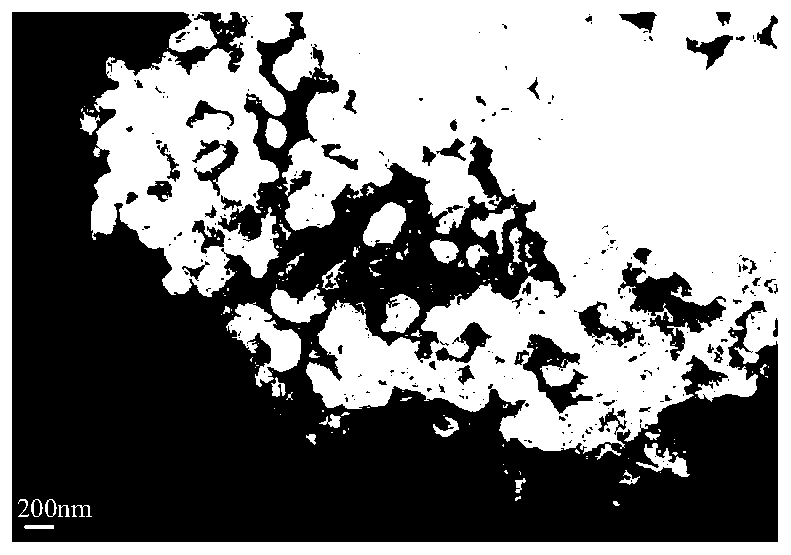

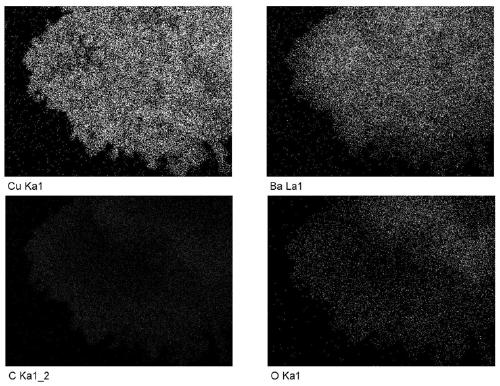

[0027] Accurately weigh 0.08g BaCO 3 , 1g of anhydrous formic acid and 20mL of 1,4-dioxane were added to a 50mL autoclave, sealed, and stirred at 200°C for 30min. After cooling, add 0.43g Cu(HCOO) to the above reaction solution 2 4H 2 O, sealed reactor, N 2 Replace 3 to 5 times to evacuate, and react at 170°C for 30 minutes. After cooling, centrifuge, wash, and dry under vacuum at 60°C to obtain 60% Cu-BaCO 3 Composite catalyst. In a similar way, changing Cu(HCOO) 2 4H 2 O and BaCO 3 The amount of addition, the preparation of different mass fractions of Cu-BaCO 3 Composite catalyst.

[0028] The above Cu-BaCO 3 Add 0.3g of catalyst, 0.6g of furfural and 20mL of 1,4-dioxane into the reaction kettle, then add 1.15g of anhydrous formic acid, after mixing and sealing, use N2 Replace the air 3 to 5 times to discharge the air, react at 170°C for 2 hours, the conversion rate of furfuryl alcohol is 100%, and the selectivity is 99%. Under the same conditions, use 2MPa H 2 I...

Embodiment 3

[0030] Accurately weigh 0.08g BaCO 3 , 0.02g of anhydrous formic acid and 20mL of 1,4-dioxane were added to a 50mL autoclave, sealed, and stirred at 170°C for 30min. After cooling, add 0.43g Cu(HCOO) to the above reaction solution 2 4H 2 O, sealed reactor, N 2 Replace 3-5 times to empty, and react at 170°C for 60min. After cooling, centrifuge, wash, and dry under vacuum at 60°C to obtain 60% Cu-BaCO 3 Composite catalyst.

[0031] The above Cu-BaCO 3 Add 0.3g of catalyst, 0.6g of furfural and 20mL of 1,4-dioxane into the reaction kettle, then add 1.15g of anhydrous formic acid, after mixing and sealing, use N 2 The air was replaced 3 to 5 times, and the reaction was carried out at 170° C. for 2 hours. The conversion rate of furfuryl alcohol was 58%, and the selectivity was 97%. Under the same conditions, use 2MPa H 2 Instead of formic acid, the conversion rate of furfural is 41%, and the selectivity is 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com