A multi-source driven ultrasonic atomization device

An ultrasonic atomization and source-driven technology, applied in the direction of spraying devices, liquid spraying devices, etc., can solve the problems of poor film quality, slow deposition speed of ultrasonic atomized droplets, slow spraying speed of atomized droplets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

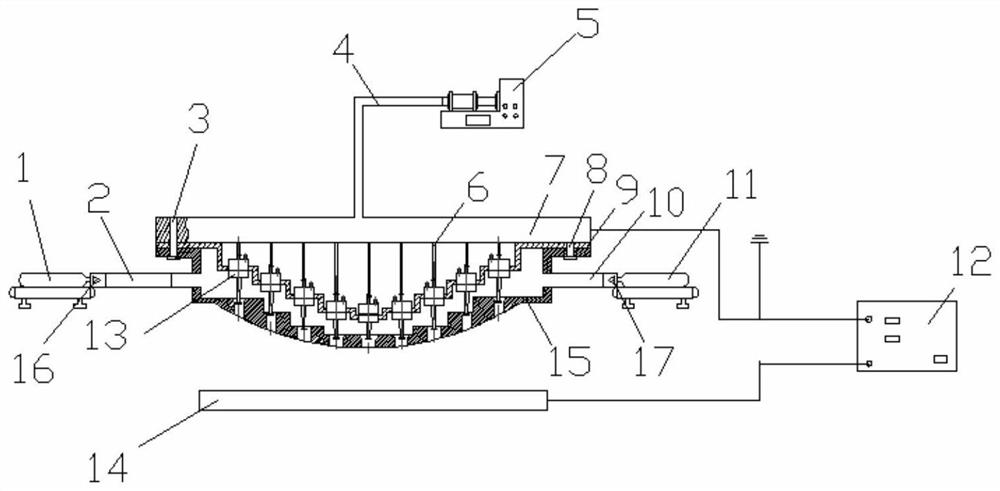

Embodiment 1

[0022]Seefigure 1 , A multi-nozzle multi-source driven ultrasonic atomization device of this embodiment 1, including a controllable injection pump 5, a liquid conduit 4, a liquid dispensing device 7, a gas hood 15, a high-voltage power supply 12 and a collection plate 14. The controllable The injection pump 5 is connected to one end of the liquid conduit, and the other end of the liquid conduit 4 is connected to the liquid inlet 6 of the liquid dispensing device 7. The gas hood 15 is arranged in the direction of the liquid dispensing device 7 and the collecting plate 14 is arranged on the liquid dispensing device 7. Below the device 7 and the gas hood 15, the high-voltage power supply 12 is electrically connected to the liquid separating device 7 and the collecting plate 14, and further includes a supporting plate 9 and an ultrasonic device 13, and the supporting plate 9 is arranged on the liquid separating device 7 and the gas Between the hoods 15, the ultrasonic device 13 is arran...

Embodiment 2

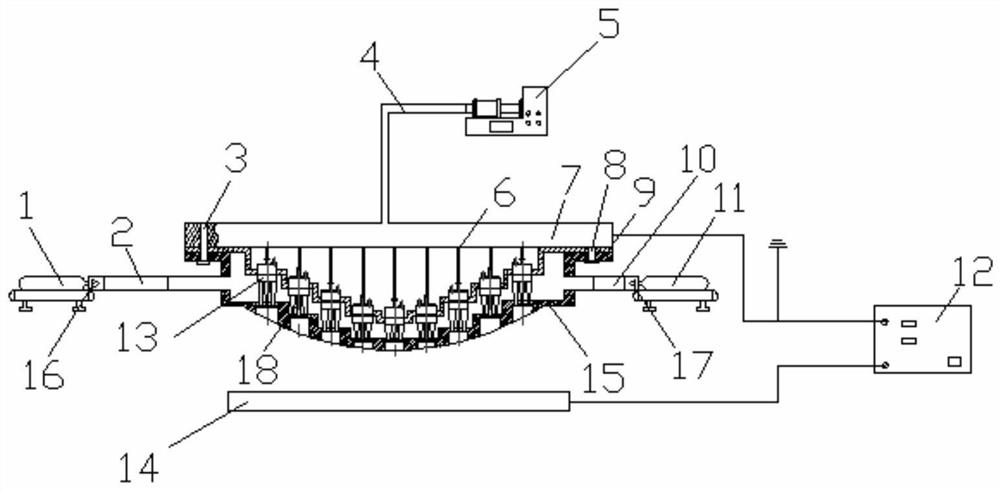

[0031]Seefigure 2 The structure of a multi-nozzle multi-source-driven ultrasonic atomization device of the second embodiment is basically the same as that of the first embodiment, except that the number of nozzles 18 corresponding to the ultrasonic device 13 is multiple.

Embodiment 3

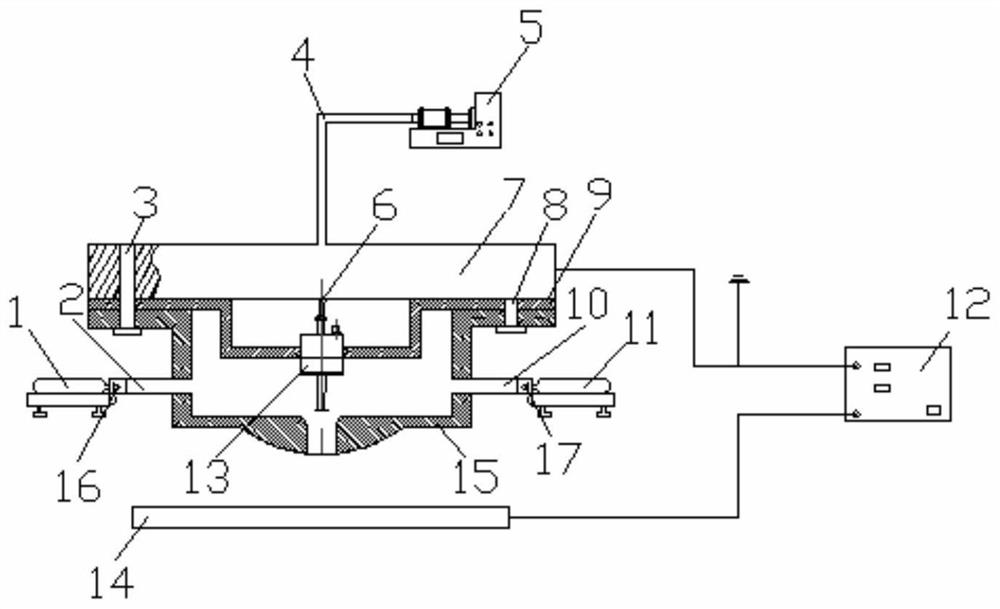

[0033]Seeimage 3The structure of a single-nozzle multi-source driven ultrasonic atomization device of this embodiment 3 is basically the same as that of embodiment 1, except that in this embodiment, a single ultrasonic device 13 is provided on the support plate 9 .

[0034]In this embodiment, the ultrasonic atomized droplets can be quickly and accurately attached to the collecting plate under the guidance of the high-voltage electrostatic field and the auxiliary airflow, thereby improving the spraying efficiency of the atomized droplets. In addition, under the action of a high-voltage electrostatic field, the surface of the atomized liquid droplets are charged, which repel each other, which overcomes the problem of the accumulation of droplets that affects the uniformity of film formation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com