Rotor die-casting machine

A die-casting machine and rotor technology, applied in the field of rotor processing, can solve problems such as troublesome operation, achieve production safety, reduce burns to operators, and facilitate separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

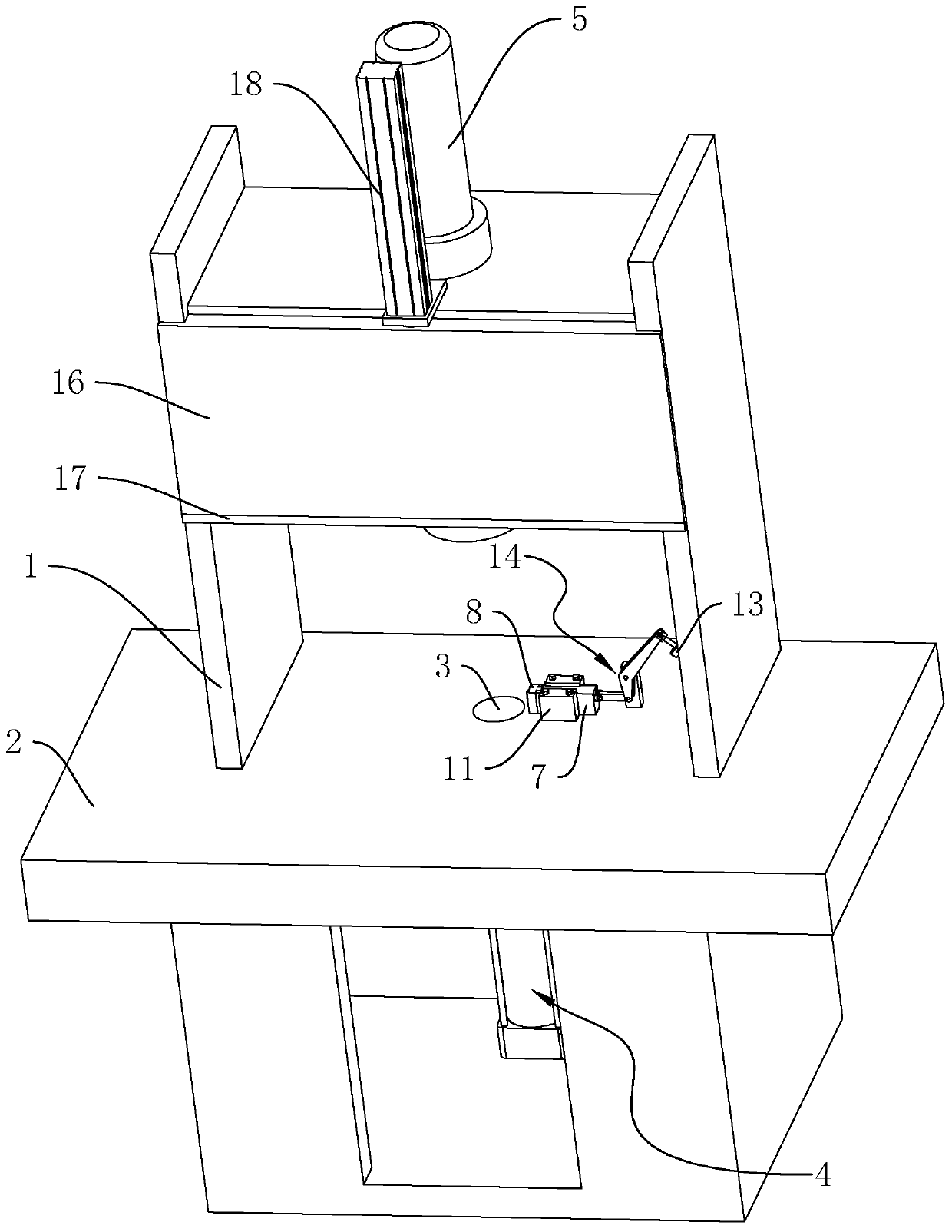

[0040] A rotor die casting machine such as figure 1As shown, it includes a frame 1, a stage 2 arranged on the frame 1, an aluminum water tank 3 set on the stage 2, an injection assembly 4 arranged under the aluminum water tank 3, and a set on the frame 1. Compress oil cylinder 5. The aluminum water tank 3 is cylindrically arranged, the compression cylinder 5 is vertically arranged, and the piston rod of the compression cylinder 5 is arranged towards the object stage 2, and the piston rod of the compression cylinder 5 is also provided with a compression block, and the compression cylinder 5 is compressed on the mold 6 by a pressing block.

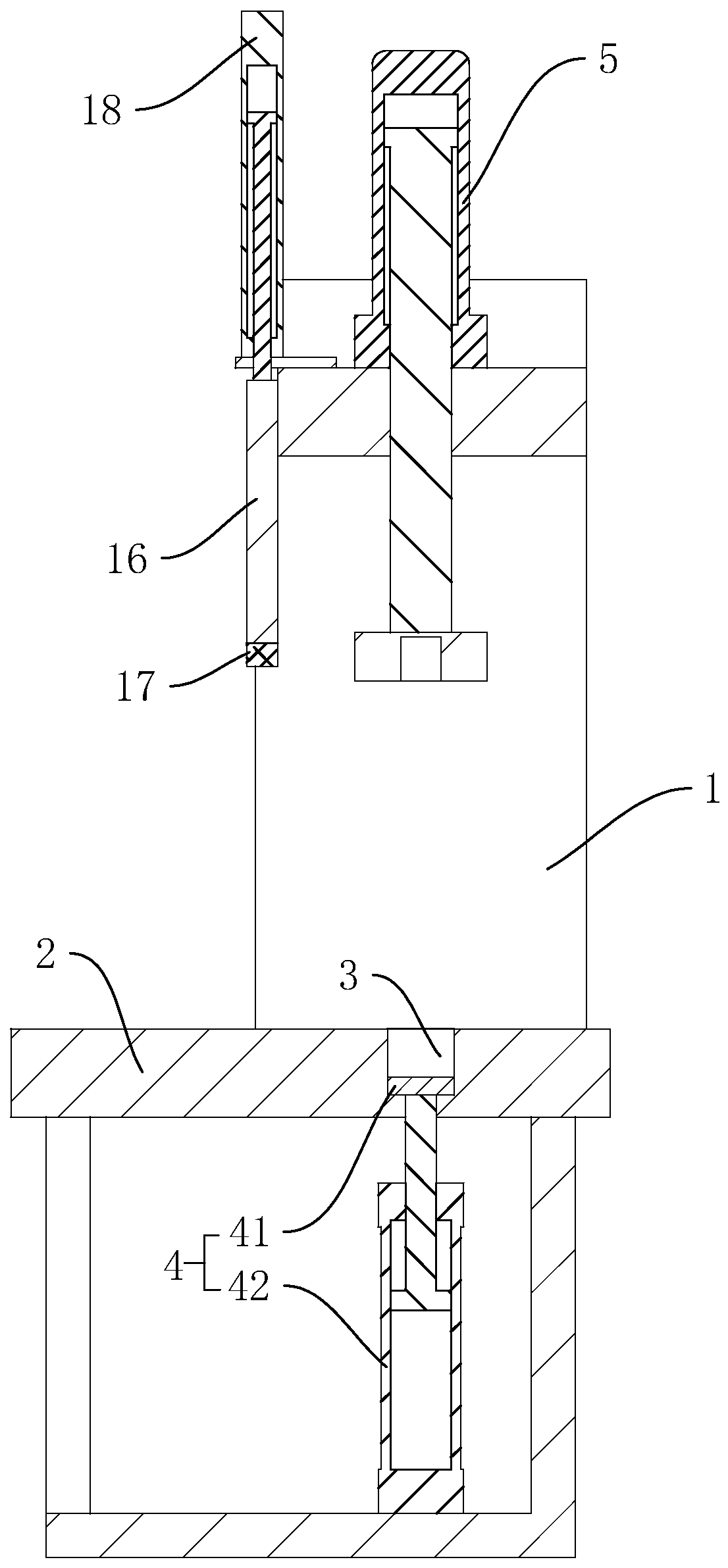

[0041] Such as figure 2 As shown, the injection assembly 4 includes an extrusion plate 41 sliding in the aluminum water tank 3, and an injection cylinder 42 arranged on the frame 1. The piston rod of the injection cylinder 42 is vertically arranged and connected to the extrusion plate 41. The lower bottom surface is connected, and the si...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap